Practical LED bulbs are now available from a number of sources. One manufacturer, Cree, Inc., reached a milestone in LED lighting with the development of a 75-watt replacement bulb more than 100 years after Thomas A. Edison produced the first practical incandescent lamp. Thus, LED bulbs can now replace traditional incandescent bulbs that lack the efficiency you would expect of nearly any other piece of modern technology. In fact, about 90% of the energy they use is wasted as heat in incandescents, with only the remaining 10% actually producing light.

Early LED bulbs weren’t a good replacement for Incandescent lamps. One reason is that LED’s produce a directional point of light, so bulbs with a single LED didn’t give off the same omnidirectional glow that incandescents do. Therefore, early attempts to replicate Edison bulbs with LEDs were expensive and looked different from what the average consumer would recognize.

Cree succeeded by developing a bulb that imitated Edison’s invention by giving off light similar to that of incandescents. Even the shape and look of the Cree bulb is virtually indistinguishable from old-school bulbs — a huge boon in getting people to adopt the new technology.

Engineering innovation was the key to Cree’s success. Besides affordable cost, the company focused on six key engineering issues in the design of the 75-W replacement bulb:

1. Bulb brightness

2. Bulb appearance

3. Light distribution similar to the light dispersed by an incandescent.

4. Acceptable light color quality, .i.e., the ability of the light to reproduce colors of various objects relative to how they look in natural light (known as CRI or color rendering index).

5. Efficiency

6. Usable lifetime

Cree produces LEDs so they have a controlled source of these semiconductors. A key innovation was the way they packaged LEDs in a way that distributed the light, provided thermal management, and was cost effective. Seen in Fig. 1 was Cree’s approach called a “Filament Tower™.” Ten LEDs are arranged around the top of the tower so that the produced light was omni-directional. The series of LEDs produce light at the center of the bulb that gives off an even light resembling the glow of an incandescent filament.In addition, the Tower provided thermal management to dissipate heat from the LEDs and enhance reliability, and useful lifetime.

The bulb shape is similar to the traditional incandescent bulb (Fig. 2). Although U.L. didn’t require it traditional incandescent bulbs, they wanted the LED types to be shatter resistant. Therefore, Cree deposited a silicone coating on its 75-W replacement bulb. U.L. required that despite the fact that an LED bulb could continue operating if the bulb cracked, whereas a crack on an incandescent would render it useless.

Cree’s LEDs are higher voltage types that simplify the associated drive circuits. Phosphors used with the LEDs provide a “soft white” 2700K color temperature. The 75-W bulb consumes 13.5 W and produces 1100 lumens. CRI is 80.

These bulbs have the same glass dome as incandescent lights and there isn’t a noticeable metal heat sink. The first wave of general-purpose LED products have heavy metal fins that draw away heat from the LED light sources.

Although the LEDs can have a long useful lifetime like most semiconductors, the other internal electronic components must be able to operate reliably as well as the semiconductors. A key passive component in converting ac to dc is the filter capacitor. However, Cree takes special care on the use of electrolytic. The company says it has carefully designed, tested and verified the reliability of the capacitors and ensures they will outlive the 10-year warranty.

If you use the bulb three hours a day, then over a year’s time it will draw about 15 kW-Hours. At roughly 10 cents per KWH that’s about $1.50 in electricity per year. In comparison, an old 75-watt incandescent would use about 82 KWH, costing about $8.20. Initially, the retail price of the Cree was $23.97 and recently was reduced to $19.97. Therefore, the payback time for the bulb is about 30 months.

As part of its ongoing mission to drive 100-percent adoption of LED lighting, Cree, Inc. has earned ENERGY STAR® qualification for its soft-white Cree® LED Bulbs. ENERGY STAR qualification signifies these Cree LED bulbs now qualify for incentive rebates through certain local utilities. Not only do the ENERGY STAR-qualified Cree LED bulbs look and light like traditional incandescent bulbs, use 84 percent less energy and last 25 times longer than typical incandescents, but now they will be even more affordable in select markets with utility rebates.

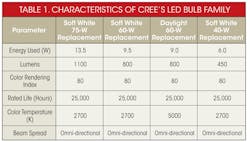

Table 1 lists the characteristics of Cree’s line of LED bulbs.

About the Author

Sam Davis Blog

Editor-In-Chief - Power Electronics

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.