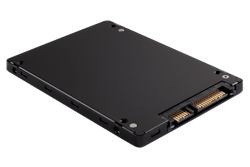

Micron’s latest crop of NAND flash memory products comes in three form factors: a 2.5-in., SATA solid state drive (SSD), an M.2 SATA drive, and an M.2 NVMe drive. All utilize Micron’s 32-layer, 3D NAND flash technology that allows the 1100 SSD 2.5-in SATA drive (Fig. 1) to hold 2 Tbytes. The drive has a 6 Gbit/s SATA III interface. It can deliver 540 Mbyte/s and 500 Mbyte/s sequential read and write transfers. It handles 92 and 83 random read and write IOPS. The 2 Tbyte drive should deliver at least 400 TBW (Tbytes written).

The drives incorporate a range of features including data at rest power loss protection and Micron’s Adaptive Thermal Monitoring. The drives are S.M.A.R.T.-enabled and there is optional TCG Opal Encryption support. The drives employ Dynamic Write Acceleration to improve performance. This utilizes SLC (single level cell) for faster write operations, then migrates the data to TLC (three level cell) for higher capacity in the background.

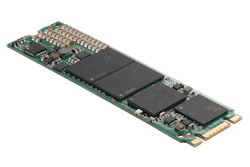

The M.2 1100 SSD (Fig. 2) stores up to 1 Tbyte using TLC 3D NAND in a single-sided M.2 form factor. Like the 2.5-in drive, the M.2 1100 SSD is up to 900 times faster than a conventional hard disk drive (HDD). The M.2 2100 SSD uses a faster PCI Express interface that allows it to deliver up to 1,900 times the performance of an HDD. All three SSDs are more power-efficient than an HDD.

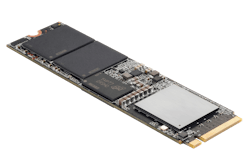

The M.2 2100 SSD (Fig. 3) has a x4 PCI Express interface instead of the 1100’s SATA III interface. It will be available later this year. The PCI Express interface helps deliver the higher throughput available with NVMe (non-volatile memory express) support. The 2100 SSD uses MLC 3D NAND; it is a double-sided board, rather than single-sided like the 1100 M.2 SSD.

The 2.5-in drive provides higher-capacity storage, while the M.2 form factor works for mobile devices. It is also becoming more popular on motherboards, allowing more compact PCs and all-in-one PC solutions. The M.2 solutions are also becoming more popular for embedded applications.

Looking for parts? Go to SourceESB.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.