Make the Timely Move: Add a UPS to Your Battery/Cell Tester

Battery and cell testing can take many hours and produce large volumes of data. Engineers need to protect their time invested in processing the batteries/cells and collecting that data. One of the hazards to protect against is a loss of ac power to the system that’s charging, discharging, collecting, and storing measurements. An uninterruptible power supply (UPS) is a common tool to use to maintain power locally when the ac mains or grid can’t be relied upon.

Protecting Batteries/Cells and Data During R&D

In the case of testing batteries/cells in R&D, cell design validation or qualification is performed. These tests can run for days or weeks, collecting a large volume of test data. If battery/cell cycling is complete, these tests could run for weeks or even months. An ac power loss may interrupt the testing, but in most cases, testing can be resumed immediately after power is restored. Still, it’s important to protect the test data and ensure it’s safely stored to local or remote storage without loss caused by the power blackout. A UPS can be employed here to ensure the data gets to its final destination.

A cautionary consideration: Battery/cell tester hardware needs to be robust, such that when ac power is unexpectedly removed, the tester hardware immediately goes into a high-impedance state. Therefore, the unpowered channels don’t act as loads on the battery/cell, drawing down the state-of-charge (SoC) in an uncontrolled way, or worse, acting as shorts on the batteries/cells, which can have hazardous results.

Protecting Cells and Data During Manufacturing

In the case of testing cells in manufacturing, the primary activity is cell formation and grading. This process can take 5 to 20 days, depending on the cell manufacturer’s process. Should an ac power loss interrupt the formation and grading, it’s important to protect the cell measurement data and ensure it’s safely stored to local or remote storage without loss of data. Once again, a UPS can be employed here to ensure the data gets to its final destination.

Beyond data protection, you need to consider the impact of power loss on the electrical processes happening to the cell during this 5- to 20-day period. The bulk of this time is spent in aging, where the cells aren’t connected to anything. Thus, during aging, a loss of ac power will have little impact on the cells. During formation, when the cells are being charged and discharged under very specific and controlled conditions, a loss of ac power can be disastrous.

If power is lost briefly, as in under a minute, most manufacturers will just pick up and resume the formation process where it left off. For longer power losses, this long interruption acts like a rest step unexpectedly inserted in the carefully selected charging/discharging profile used to form the cells. Adding this unexpected rest step means this batch of affected cells is now different, in an unknown way, from the other cells that are produced. These cells may have to be scrapped or reworked.

While a UPS could protect data storage, it's probably not feasible to use a UPS to ensure the formation process (charging/discharging) continues without interruption. First, the formation process is happening on many cells simultaneously. In the case of a large factory, there could be hundreds of thousands of cells being charged/discharged at the same time, consuming megawatts of power. Employing one or many UPSs to continuously power the cell formation electronics during a blackout would be prohibitively expensive, as would using UPSs to even briefly hold up the formation electronics while waiting for giant backup generators to kick in.

Furthermore, because most cell formation equipment is regenerative, the UPS (and/or backup generator) would need to be a very complex design to support power flow—from the ac line through the UPS into the cell formation system (during charge), and from the cells through the formation system, through the UPS back to the ac line (during discharge). Due to the size and complexity, protecting the ac power of formation systems is just not done.

Use the UPS to Protect Data

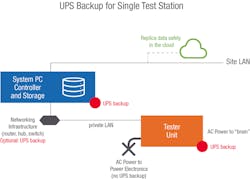

Protecting data is the main reason to add UPS to battery/cell testers, so where do you need to put the UPS? There are several points in the system to be protected (Figs. 1 and 2).

Protect the “brain”

The control system that’s closest to the batteries/cells needs to be protected. This could be the processor inside the battery/cell tester or the PC that’s running the tester control software. In a large distributed system, this would be the edge computer at that test station.

My recommendation: Put a UPS on the tester’s low-power ac input (standard wall plug, not high power 3-phase input) and on any PC that’s connected directly to the tester. This will ensure that any power loss keeps the “brain” alive and allows any residual data collected immediately before the power loss to be stored on the local PC. It will also allow for later analysis of the impact of the power-loss event, as in what happened just prior to the event; what happened to the batteries/cells as the power was lost; and what was the final state of the cells prior to shutdown.

The UPS doesn’t need to be large. It should have sufficient capacity or runtime to collect and store the final in-process measurements and then enable an orderly shutdown of the system. Five or ten minutes of runtime should be sufficient.

Protect servers

In a large system, a distributed computing platform is likely to be used. The central server cluster for the battery/cell testers should be protected by a UPS. It should have sufficient capacity or runtime to collect and store any final measurements flowing through the network and then allow for an orderly shutdown of the servers. Ten to fifteen minutes of runtime should be sufficient.

Protect storage

Today, it’s common for PCs to store data into centralized on-premises file servers. While the individual PCs in the system are recommended to be protected by their own UPS, the file servers that store large datasets should also be protected by a UPS. Note that if the centralized file servers are a duplicate backup to the local storage on the individual PCs, then protecting central storage may not be necessary. Another consideration is off-site cloud storage, where data backup is managed by a third-party provider. Off-site cloud storage eliminates the need to protect on-premises storage against local power failures.

Protect networking

In distributed systems, Ethernet is the common site-wide communications infrastructure. When the power goes out, the network goes out. Therefore, switches, hubs, and routers should also be on a UPS if you’re relying on the network to get data from distributed testers back into a battery/cell tester server cluster, on-premises bulk storage on a file server, or even off into the cloud. Once again, if the cloud or on-premises centralized file servers are a duplicate backup to the local storage on the individual PCs, then protecting the network infrastructure may not be necessary.

Bob Zollo is the Solution Architect for Battery Testing, Electronic Industrial Solutions Group, at Keysight Technologies.

About the Author

Bob Zollo

Solution Architect for Battery Testing, Electronic Industrial Solutions Group

Bob Zollo is solution architect for battery testing for energy and automotive solutions in the Electronic Industrial Solutions Group of Keysight Technologies. Bob has been with Keysight since 1984 and holds a degree in electrical engineering from Stevens Institute of Technology, Hoboken, N.J. He can be contacted at [email protected].