Flexible Supercaps Enable Body-Sensing Harvesting-Powered Apps

Supercapacitors are widely used for energy storage and often associated with harvesting applications. However, their physical rigidity makes them a less-than-desired option for many such situations, especially those that use a body’s motion as the energy source. Among the limitations of conventional micro-supercapacitors, with their “sandwich-like” stacked geometry, are poor flexibility, long ion-diffusion distances, and a complex integration process when combined with wearable electronics.

Now, a research team based at Pennsylvania State University (Penn State), along with members from Minjiang University and Nanjing University (both in China), has devised and tested planar micro-supercapacitor arrays (MSCAs) (Fig. 1). These are based on hybrid electrodes using ultra-thin zinc-phosphor (Zn3P2) nanosheets anchored on 3D laser-induced graphene foams (ZnP@LIG), which are arranged in an island-bridge device architecture. The MSCAs can complement or replace lithium-ion batteries in wearable devices due their small footprint, high power density, and the ability to charge and discharge quickly.

Led by Prof. Huanyu “Larry” Cheng, the team explored alternative device architectures and integration processes to advance the use of micro-supercapacitors in wearable devices. They found that arranging micro-supercapacitor cells in a serpentine, island-bridge layout enables the configuration to stretch and bend at the bridges, while reducing deformation of the micro-supercapacitors (the islands). Hence the designation as micro-supercapacitors arrays.

Prof. Cheng noted, “By using an island-bridge design when connecting cells, the micro-supercapacitor arrays displayed increased stretchability and allowed for adjustable voltage outputs. This allows the system to be reversibly stretched up to 100%.”

By using non-layered, ultra-thin zinc-phosphorus nanosheets and 3D laser-induced graphene foam—a highly porous, self-heating nanomaterial—to construct the island-bridge design of the cells, Cheng and his team saw significant improvements in electric conductivity and the number of absorbed charged ions.

The MSCA numbers tell the story: The hybrid electrodes with a large specific surface area demonstrate excellent ionic and electrical conductivities, with gravimetric and areal capacitances of 1425 F/gram and 7.125 F/cm2 at 1 A/gram, respectively. In addition, they achieved high energy density of 245 mW-hr/cm2 along with power density of 12.50 mW/kg at 145 mW-hr/cm2. They adjusted and controlled voltage- and current-output ratings as needed by varying serial and parallel connections of MSCA cells within the island-bridge design.

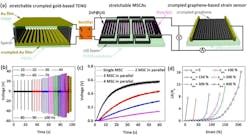

The basic MSCA numbers alone are only part of the story. The team integrated stretchable MSCAs with a “crumpled” Au-based triboelectric nanogenerator (TENG) plus a stretchable, crumpled graphene-based strain sensor to demonstrate a self-powered, energy-harvesting stretchable system (Fig. 2).

These MSCAs with adjustable voltage/current outputs can be reversibly stretched to 100% and integrated with a TENG and sensors to create a viable solution for a self-powered stretchable system. The details are in their paper published in Nano Energy with the formidable title, “High-energy all-in-one stretchable micro-supercapacitor arrays based on 3D laser-induced graphene foams decorated with mesoporous ZnP nanosheets for self-powered stretchable systems.”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.