What’s the Difference Between Monolithic and Modular UPS Systems?

This article is part of TechXchange: Power Supply Design

What you’ll learn:

- Why UPS systems are needed.

- Differences between monolithic and modular UPS systems in relation to cost, simplicity, and reliability.

- Key benefits and downsides of each system design.

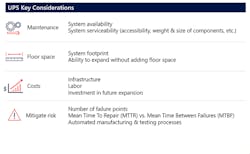

Increasing demand for reliable power, coupled with the growing use of essential electrical equipment and digitization, is driving up adoption of uninterruptible power supply (UPS) systems. While data centers, hospitals, and manufacturers were among the first to adopt the technology, demand for UPS systems is expanding to other users such as research facilities, schools, or anywhere with critical power applications. Considering the high stakes associated with energy failure, what are the most important factors to consider when choosing such a system?

UPS system design boils down to two main types: monolithic or modular. The original UPS design, the monolithic system, is a solution made of single subsystems including one static switch, one rectifier, one inverter etc.—but importantly, they have no intrinsic redundancy.

The more recently developed modular UPS, as the name suggests, consists of several smaller components that can be added or removed to scale the solution up or down. Looking at both UPS solutions, we will analyze the benefits of each in relation to three main decision criteria—cost, reliability, and simplicity.

Cost: Is It All About Price?

When making any investment, cost is always the primary consideration. When it comes to UPS systems, and if comparing systems of a similar power requirement, the monolithic solution has the lower initial price tag.

That’s why, traditionally, the monolithic UPS has been the solution of choice for organizations with smaller power requirements—especially if their needs are unlikely to change in the near future. However, for those businesses with larger power requirements or where increased flexibility is needed, there’s more to consider.

Different model sizes of monolithic systems are available, but there’s less flexibility in terms of power capacity than with modular UPS. Subsequently, monolithic UPS users often end up paying more for a system that’s larger than they need to reach their power requirements. In addition, should their power requirements change due to a lack of design flexibility, a whole new monolithic system is often required.

That underscores one of the strengths of modular UPS. To increase the capacity of your modular system, it’s as simple as buying additional power modules and slotting them into your existing rack. What’s more, should you have multiple modular UPS solutions at your facility, you also can swap modules from system to system to address changing load profiles, increasing efficiency savings and mitigating risk.

Reliability: When You Can’t Afford to Fail

Designed to ensure that your power supply is reliable and uninterrupted, a UPS system must be extremely robust and reliable. Obviously, this is critical when powering lifesaving medical equipment or other essential electrical devices.

Traditional monolithic systems feature a simple design. Consisting of fewer individual components, this means that less failure points are in the system. Alternatively, modular UPS solutions spread the load over many more components, which could bring up the argument that it provides many more potential failure points.

However, in a monolithic system, failure of one component could cause failure of the entire system. But in true modular units, if one module fails, it’s separated from the rest of the system and the other modules pick up the slack to ensure continued operation/power. This is a key distinction between modular systems: Not all modular solutions are the same, and only “true modular” UPS, like our SolarEdge solutions, provide this functionality.

Like many things in life, being handmade is generally better. UPS systems are not one of those things, though.

While large monolithic solutions are manufactured manually with the attendant risk of human error, smaller power modules for modular UPS systems are manufactured and tested utilizing automated solutions. This approach adds to reliability, with each of these smaller modules also being machine tested before shipping—something that doesn’t occur within the monolithic manufacturing process.

Simplicity is Key

Thankfully, failure of a UPS system is uncommon, but replacing individual components as part of regular system maintenance is both expected and planned. Ensuring that your system remains operational, or that you have backup power during those service intervals, can be a big issue with considerable consequences for your operation.

In this case, modular UPS systems are relatively easy to maintain. In a true modular solution, each essential part is hot-swappable and can be removed for maintenance or replaced while the system continues to run.

Conversely, a monolithic system will likely need to be shut down for maintenance of core components. Thus, you either lose your backup facility during this period, or you have to switch to another system, essentially meaning that you need two units to provide the same service. And that comes with all of the associated costs of purchasing, installing, and maintaining two UPS devices. Some users also install two modular UPS systems for ultimate peace of mind, but this trend is beginning to change—depending on the load’s criticality, it’s often not necessary.

Crucially, and unlike the modular approach, if certain individual parts fail in a monolithic environment, the process of replacing them is often complex and time-consuming. Usually, it requires a specialist UPS engineer, representing additional downtime and cost.

Summary

Both UPS systems are reliable, but they employ completely different designs to provide different levels of flexibility and autonomy. For organizations with lower critical power application requirements, a monolithic solution will be both cheap to install and generally fit for purpose.

But, as we’ve explored, you also could be installing a system that’s larger and more expensive than you need, as well as being more costly to maintain in the long run. Plus, should your power requirements change, and you need to add more capacity, monolithic solutions don’t have the system flexibility to support you.

For organizations that require ultimate reliability and no downtime, a modular UPS system is very appealing, although they do look more expensive. But, when the total cost of ownership is calculated, considering ease of maintenance, a smaller floorspace footprint, and overall system flexibility, the modular argument becomes very compelling.

Read more articles in TechXchange: Power Supply Design

About the Author

Luke Eiland

Service Manager, SolarEdge Critical Power Division

Luke Eiland is the Service Manager for the SolarEdge Critical Power Division, which delivers innovative products and solutions that power critical computers, storage, and machines in a broad range of sectors.