Ultra-Thin Solar Cells Easily Conform, Bend, and Even Flex

What you’ll learn:

- How an ultra-thin, flexible solar cell was fabricated.

- How the resultant solar cell was attached to a strong, ultra-lightweight, flexible fabric carrier.

- The results of the electrical and mechanical tests.

While overall efficiency (watts/unit area) and cost are primary metrics for solar cells—and there are many others, of course—another important but often overlooked parameter is power output versus weight. Conventional larger-area silicon solar cells are fragile, so they must be encased in glass and packaged in heavy, relatively thick aluminum framing, which limits where and how they can be used.

Now, a research team at MIT’s Organic and Nanostructured Electronics Laboratory (ONE Lab) has developed ultra-light, fabric-mountable solar cells that can quickly and easily make nearly any surface into a power source.

These durable, flexible organic photovoltaic (OPV) solar cells are glued to a strong, lightweight fabric, making them easy to install on a fixed surface, or even a flexing one such as a sail. They are one-hundredth the weight of conventional solar panels and generate 18X more power-per-kilogram. As an additional virtue, they’re made from semiconducting inks using printing processes that can be scaled to large-area manufacturing.

Creating the Ultra-Light OPV Solar Cells

The effort is more than a “routine” extension of their past research. Six years ago, the ONE Lab team produced solar cells using an emerging class of thin-film materials that were so lightweight they could sit on top of a soap bubble.1 However, these ultra-thin solar cells were fabricated using complex, vacuum-based processes that were expensive and challenging to scale up. As a result, they decided to try to develop thin-film solar cells that are entirely printable, using ink-based materials and scalable fabrication techniques.

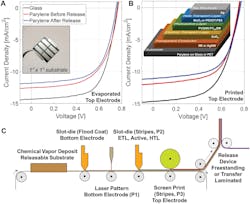

In the new approach, they coat the solar-cell structure using a slot-die coater, which deposits layers of the electronic materials onto a prepared, releasable substrate that’s only three microns thick (Fig. 1). Using screen printing (similar to how designs are added to silkscreened T-shirts), an electrode is deposited on the structure to complete the solar module. The researchers can then peel the printed module, which is about 15 microns thick off the plastic substrate, forming an ultra-light solar device with an areal density of just 105 g/m2 (0.344 oz/ft2).

Finding the Right Substrate

Unfortunately, this thin film makes for a very fragile and thus impractical solar cell. To rectify this unacceptable deficiency, they searched for a lightweight, flexible, and high-strength substrate to which they could adhere the cell. They identified fabrics as the optimal solution, as they provide mechanical resilience and flexibility with little added weight. After further investigation, they chose a composite ultra-light fabric known commercially as Dyneema. It weighs only 13 g/m2 (0.043 oz/ft2) and is used in applications such as high-strength ropes and fabric sheets.2

By adding a layer of UV-curable glue that’s only a few microns thick, they adhered the solar modules to sheets of this fabric. This forms an ultra-light and mechanically robust solar structure.

“While it might appear simpler to just print the solar cells directly on the fabric,” said team co-leader Mayuran Saravanapavanantham, an electrical engineering and computer science graduate student at MIT, “this would limit the selection of possible fabrics or other receiving surfaces to the ones that are chemically and thermally compatible with all the processing steps needed to make the devices. Our approach decouples the solar-cell manufacturing from its final integration.”

Performance Assessment

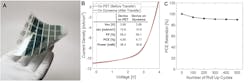

Completed devices were tested inside a nitrogen-filled glovebox, under AM1.5 simulated solar irradiation with the simulator was adjusted to 1 sun with a calibrated reference cell.3 Each test module was comprised of five serially connected cells, each with an active area of 1.5 cm2 (Fig. 2).

The researchers determined that it could generate 730 W/kg when freestanding and about 370 W/kg when mounted on the high-strength Dyneema fabric, which is about 18X more than conventional solar cells offer against this metric. They also assessed the durability of the result by rolling and unrolling a fabric solar panel more than 500 times and determined that the cells still retained more than 90% of their initial capabilities.

They do acknowledge some drawbacks. While these solar cells are far lighter and much more flexible than traditional cells, the carbon-based organic material used to make them could be “corrupted” due to interaction with moisture and oxygen in the air. This, in turn, could deteriorate their performance, and so they would need to be encased in another material to protect them from the environment.

To address this critical issue, they’re currently developing ultra-thin packaging solutions that would only fractionally increase the weight of the present ultra-light devices.

This research was funded in part by Eni S.p.A. through the MIT Energy Initiative, the U.S. National Science Foundation, and the Natural Sciences and Engineering Research Council of Canada. Details are in their paper “Printed Organic Photovoltaic Modules on Transferable Ultra-thin Substrates as Additive Power Sources” published in Small Methods, along with a Supporting Information file. Also, check out this interesting two-minute video:

References

1. MIT, “Solar cells as light as a soap bubble”

2. Avient Corp., “Dyneema”

3. PV Education, “Standard Solar Spectra”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.