Hybrid Cathode Synergy Yields Sharply Improved Li-S Battery Metrics

Improved battery technology isn’t just a matter of better electrolytes or physical configuration, but also the electrodes—anode and cathode—of the cell. An MIT-led team led by Ju Li, professor of nuclear science and engineering and of materials science and engineering, and Weijiang Xue, an MIT postdoctoral student (plus 13 others) has focused on the cathode and the tradeoffs in cathode material and fabrication. The team devised what they say is a dramatic improvement in cathode performance and, thus, the battery’s performance.

Most Li-ion batteries have cathodes fabricated from a transition metal oxide, but lithium-sulfur batteries face a tradeoff. Their cathodes can be made in one of two ways:

• The intercalation type uses compounds with high volumetric energy density, such as lithium cobalt oxide. These cathodes maintain their structure and dimensions while incorporating lithium atoms into their crystalline structure.

• The conversion type uses sulfur that’s transformed structurally and temporarily dissolved in the electrolyte. “Theoretically, these [batteries] have very good gravimetric energy density,” says Li. “But the volumetric density is low,” partly because they tend to require a lot of extra materials, including an excess of electrolyte and carbon, used to provide conductivity.

The researchers merged the two approaches into a single cathode using a type of molybdenum sulfide called Chevrel-phase Mo6S8 along with pure sulfur (Fig. 1), a combination that provides the best attributes of both but without their weaknesses. The electrical conductivity of the combined material is relatively high, which reduces the need for carbon and shrinks the overall volume about 20% to 30% in typical sulfur cathodes to about 10%, notes Li.

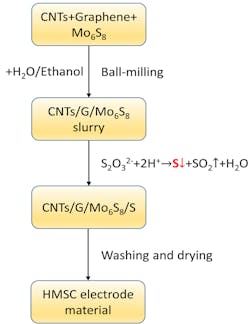

1. This high-level overview of the chemical fabrication process for the hybrid molybdenum sulfur carbon (HMSC material) doesn’t show all of the details, which are provided in the published paper and supplementary material. (Source: MIT)

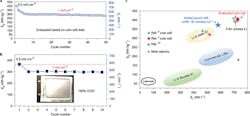

The new design provides energy density of 360 W-hr/kg and 580 W-hr/l compared to 250 W-hr/kg and 700 W-hr/l, respectively, for a commercial Li-ion battery, and 400 W-hr/kg and 400 W-hr/l for a Li-S battery (Fig. 2). The team believes that with further refinement and optimization, they can improve those numbers. Prof Li observed, “We think we can get to 400 watt-hours per kilogram and 700 watt-hours per liter.”

2. Shown is the electrochemical performance of the Li|HMSC (hybrid molybdenum sulfur carbon) coin cell, electrochemically active Chevrel-phase 6.1 mg/cm Mo6S8, and an electrolyte-to-active material (E/AM) ratio of 2.4 µl/mg: The charge-discharge profiles (a) and rate capability (b) at various current densities from 0.5 mA/cm2 to 6 mA/cm2; cycling life and coulombic efficiency at 1 mA/cm2 (c). (Source: MIT)

Of course, batteries in the lab and batteries in production are different situations. The researchers began with small coin cells, but they have also produced cells with three-layer pouches (a standard construction) with 1 A-Hr capacity, which is in the range of commercial cells (Fig. 3).

3. The Eg and Ev of the Li|HMSC cell: The coin-cell configuration constructed by the HMSC cathode (6.9 mg/cm2 S8 + 6.8 mg/cm2 Mo6S8) with an E/AM ratio of ~1.5 µl/mg on cycling (a); the pouch-cell configuration constructed by the HMSC cathode with E/AM ratio ~1.2 μl/mg and ~2 × Li excess (100 μm for one side) (DOD = depth of discharge) (b); the comparison of projected full-cell energy densities based on the data and representative publications (c).

This new construction does have an admitted weakness: the limited number of charge/discharge cycles it can provide before losing capacity. Li believes this is mostly a function of the overall cell design rather than the new cathode itself, and notes there are many applications—long-range drones, as one example—where such cycles aren’t as critical to success as energy density by weight and volume.

Their paper “Intercalation-conversion hybrid cathodes enabling Li–S full-cell architectures with jointly superior gravimetric and volumetric energy densities,” published in Nature Energy, provides full details, along with the Supplementary Information (an unlocked version of the paper is available here). The work was supported by the Samsung Advanced institute of Technology, the National Key Technologies R&D Program of China, the National Science Foundation of China, and MIT’s Department of Materials Science and Engineering.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.