This Week in PowerBites: Radioactive Diamond Batteries?

>> Electronic Design Resources

.. >> Library: Article Series

.. .. >> Article Series: PowerBites

Nickel-Zinc Batteries Challenge Lead and Lithium for Stationary, Industrial Apps

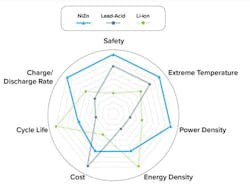

Zinc-based batteries are usually associated with the cheap but short-lived, leaky, flashlight-killing carbon-zinc primary cells. However, a new nickel-zinc-based (NiZn) battery chemistry may offer a greener, more cost-effective, solution for indoor and outdoor UPS systems, forklifts, and other specialty vehicle applications. According to ZincFive , its NiZn chemistry is similar to those used in earlier nickel-metal-hydride (NiMH) batteries, but it offers several important advantages:

- NiZn batteries have a high nominal cell voltage (1.74 V versus 1.3 V for NiMH), which requires fewer cells to produce the required output voltage. This along with the NiZn chemistry results in higher energy densities (in excess of 70 Wh/kg), significantly reducing battery footprint and weight.

- The NiZn chemistry, combined with a low-resistance cathode structure, results in substantially lower internal resistances. In turn, it produces high power densities (up to 3000W/kg) and enables rapid charge/discharge cycles with less heating and lower internal losses across a wide temperature range without the threat of damage or thermal runaway.

- ZincFive says that in most applications, NiZn batteries routinely achieve a 10+ year operating life with virtually none of the maintenance required by lead-acid batteries.

- NiZn technology is manufactured with non-toxic, widely available materials that are easily recycled, making it less hazardous for the workforce and the environment.

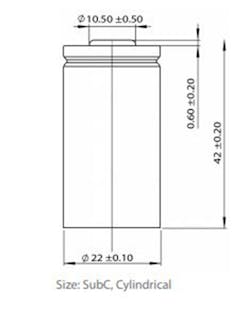

ZincFive's latest sub-C cells provide over 1800 mAh at a nominal voltage of 1.2 to 1.9 V , across a very wide temperature range. Thanks to their extremely low internal resistance, some models can support charge rates as high as 2C and discharge rates as high as 10C. For full details, click here to see the datasheet.

The company says that these and other advantages give NiZn batteries a cost per watt-hour that beats the lead-acid storage systems still lurking in the back rooms of many server farms, cell nodes, and other critical infrastructure. Just a small caveat: I suspect that they’re defining "cost competitive" in terms of total cost of ownership (TCO). So, while the cells may cost a bit more than lead-acid, their longer life, negligible maintenance, and low disposal costs make them the cell of choice for your data center (or power wall?).

Conclusion: Insufficient data at this time. I want to know about the number of discharge cycles these batteries can sustain, their suitability for Powerwall-type applications, where the battery materials come from, how they're processed, and more about their environmental footprint. Hopefully I'll be able to share the answers with you after I brief with ZincFive toward the end of the month. Between now and then, you can click here to visit ZincFive's information page.

Automotive-Rated LED Drivers Come in DFN Package with Side-Wettable Flanks

Nexperia announced a new series of LED drivers in the space-saving DFN2020D-6 (SOT1118D) package that features side-wettable flanks (SWF), thus facilitating the use of AOI (automated optical inspection). This packaging option is an industry first, according to the manufacturer. It offers equivalent performance to an SOT223 package while reducing PCB space requirements by up to 90%.

With a footprint of just 2 × 2 mm and a low profile of 0.65 mm, the new DFN2020D-6 LED drivers are available with either NPN or PNP output stages. They can deliver an output current of up to 250 mA (NCR32x types) and have a maximum supply voltage of 75 V. Their thermal dissipation capability is equal to, or better than, any other package for LED drivers in commercial use.

In addition to enabling automated inspection, the package’s side-wettable flanks also improve reliability. Studies have shown that devices with side-wettable flanks exhibit a greater resistance to shear forces, and can handle greater board flexing without cracking than similar devices in other types of packaging.

Four DFN2020D-6 LED driver products are in mass production now. More information, including product specs and datasheets, is available at www.nexperia.com/led-driver.

Wireless Power vs. COVID

Thanks to wireless power delivery, a new RFID temperature scanning system is helping businesses monitor their employees’ temperatures with a minimum of intrusion or disruption to their daily routines. The system, developed by Powercast, consists of a wirelessly powered temperature-scanning fob for each employee, an RFID reader, and a computer monitor. The fobs can easily be personalized for each employee and are small enough to fit onto a keychain.

Powercast's power-harvesting technology enables the fob to quickly charge when held near an RFID reader at the entrance to the business. Once charged, employees can use the fob to measure their temperature, which is transmitted to a central monitoring system that grants access if the reading is within the healthy range.

As shown in the video below, Powercast has already put its temperature scanning system to work at its own corporate headquarters in Pittsburgh's RIDC Park, where it took a total of 300 readings during the first 12 days of its operation:

Powering the system is Powercast's tiny, embeddable Powerharvester receiver chip, which harvests RF automatically when it's within range of an RF power source, and then converts it to direct current (dc). The chip is highly efficient at extracting usable power from even very small amounts of RF energy.

In addition to the Powercast receiver chip, each battery-free fob contains a temperature sensor, a Microchip PIC24F04KA201 microcontroller (MCU), and an RFID chip that identifies its owner. To use the fob device, an employee simply holds it in a designated power area equipped with an RFID reader antenna and a monitor. The fob the harvests the RF energy needed to power up the temperature sensor, take the reading, and transmit it to the RFID reader.

Powercast representatives say that the designer team chose Microchip's PIC24F04KA201 MCU because of its minimal power consumption and powerful development tools, which made it possible to deliver a commercially available system in less than two months.

Additional information is available from Powercast at https://www.powercastco.com/products/temperature-scanner/.

650-V MOSFETs Optimized for Resonant Topologies

A new branch of Infineon Techologies’ CoolMOS CFD7 family of MOSFETs, rated for 650-V operation, is designed to address the unique requirements of switched-mode power-supply (SMPS) designs for industrial applications. The devices' higher operating voltage and reduced RDS(on) help designers address users' demands for high efficiency and power density as well as increased bus voltages. Infineon says that the devices are best suited for resonant topologies in soft-switching applications like telecom, server, solar, and off-board EV charging.

Like all products in the CFD7 family, the new 650-V devices are optimized for LLC and zero-voltage-switching phase-shift full-bridge topologies. This includes an integrated fast body diode, improved gate charge (Qg), very low reverse-recovery charge, and excellent thermal characteristics. The 650-V CoolMOS CFD7 in TO-220, TO-247, and TO-247 4-pin packages can be ordered now. More information is available at www.infineon.com/650V-CFD7.

Virtual Prototypes Speed Compliance Testing of SIC-Based Switching Power Supplies

Designers can now perform pre-compliance testing on virtual prototypes of switched-mode power supply (SMPS) designs, thanks to an extension of the PathWave Advanced Design System (ADS) design and simulation workspace jointly developed by Keysight Technologies and ROHM Semiconductor. The companies say that the jointly created virtual prototype of ROHM's SMPS reference design (model P01SCT2080KE-EVK-001) saves time and cost by catching errors early in the design before they become a big problem.

SMPS already offer excellent efficiency, increased power density, and lower cost, with further improvements anticipated when transitioning to silicon carbide (SiC), gallium nitride (GaN), and other wide-bandgap semiconductors. Unfortunately, these new devices can also bring unwanted side effects, such as voltage spikes ("ringing") created by their higher switching speeds. Furthermore, such higher operating frequencies may make it more difficult to meet conducted and radiated electromagnetic-interference (EMI) specifications.

Pre-compliance analysis of a "virtual prototype," also referred to as a "workspace," is ideal for managing that challenge, but previously required specialized expertise to build and use the model that contains the necessary design information.

To address this, Keysight teamed with ROHM to create a virtual "twin" of ROHM's reference design. A virtualized prototype accelerates the initial evaluation and compliance testing process, and when needed, can be easily reconfigured. Thus, designers can quickly evaluate multiple "what-if" design strategies in a matter of hours. In addition, Keysight's simulation environment captures each voltage, current, and field at every spatial point in the 3D grid, at every time step in the test. It even captures data from points that are physically inaccessible in the real world, such as inside a semiconductor package.

The workspace for ROHM's SMPS reference design is available to mutual customers via Keysight's web site. Click here for more information.

Radioactive Diamond Batteries: Fact, Fiction, or Fraud?

Can radioactive diamonds be used as practical, long-lived power sources, or are they yet another "revolutionary energy" investor scam? That's what the journalists at New Atlas are trying to find out in their ongoing coverage of the so-called the nuclear diamond battery technology.

At its simplest, the technology is supposed to compress the radioactive carbon moderator elements from defunct reactors into synthetic diamonds and encase them in a multi-layered shield that contains their Beta particle emissions and converts them into modest amounts of usable electrical power. It was originally developed by a team of English researchers at the University of Bristol, who subsequently formed Arkenlight (still in stealth mode) to support its commercialization, and is now under aggressive commercialization by the California-based company NDB.

New Atlas's original story about NDB, published in August, created quite a bit of controversy on the web when NDB claimed, in a few years, it would be able to have a plug-free smartphone charger, and it would be possible to produce cells the same size as an iPhone battery that could "charge your battery from zero to full, five times an hour" for decades. Furthermore, there would eventually be plug-free electric car batteries that could provide power for the lifetime of the vehicle, or longer. Their detailed and lengthy follow-up story, published in late September, attempts to bring some clarity, balance, and scientific perspective to the issue.

While not conclusive, the story is a fascinating read. Even though some of NDB's claims appear to be overstated, the basic theory behind the technology gives the appearance of being credible, and it doesn’t resort to science-flavored "alternative facts" frequently used by techno-fraudsters like Black Light Power to swindle investors out of millions of dollars. But I'm not a physicist (although I know a few), so I remain on the fence, forming no conclusions for the moment while continuing to follow both companies.

If you have any experience with the physics behind these batteries, or its application, I'd welcome your thoughts. You can write me at: bearberg(at)gmail(dot)com.

>> Electronic Design Resources

.. >> Library: Article Series

.. .. >> Article Series: PowerBites