Members can download this article in PDF format.

Power systems employ diodes to perform a variety of functions. For example, diodes can protect against damage due to power-source reverse-polarity connections, as well as block reverse currents and transients. They also enable deployment of multiple power sources in parallel in an OR configuration to provide redundancy and load sharing.

Ideally, diodes for power systems would offer zero forward voltage drop and infinite reverse-current impedance. Although perfection isn’t achievable, several controllers and integrated devices allow you to implement ideal-diode functionality for your automotive, industrial, consumer, or other applications, thereby overcoming the limitations of the components traditionally used in power systems.

Traditional components include Schottky diodes, which, when compared with silicon p-n diodes, offer lower forward voltages. However, their forward voltage isn’t zero, and forward conduction can result significant losses at high load currents. Consequently, this often mandates the use of a heat sink, raising costs and space requirements.

In addition, the diode’s forward voltage drop cuts into the available headroom for downstream power converters, presenting a problem for automotive applications in which a battery’s voltage can drop significantly during a cold start.

As an alternative to a Schottky diode, you can use a p-channel MOSFET and a handful of other discrete components to implement reverse battery protection. However, this approach also has limitations, including poor cold-crank performance and a relatively large real-estate requirement.

Sponsored Resources:

- The basics of ideal diodes

- LM73100 2.7 - 23-V, 5.5-A integrated ideal diode with input reverse polarity and overvoltage protection

- Automotive EMC-compliant reverse-battery protection with ideal diode controllers

Ideal Diode: The Basics

To overcome the limitations of Schottky diodes or p-channel MOSFETs, you can use a reverse-polarity-protection controller such as the Texas Instruments LM74500-Q1 or an ideal-diode controller like the TI LM74700-Q1, each paired with an external n-channel MOSFET. These controllers offer significant advantages. For example, at a given power level, a solution based on the LM74500-Q1 plus an n-channel MOSFET can be one-third the size of a discrete p-channel MOSFET implementation.

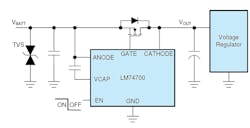

In addition to providing reverse-polarity protection, the LM74700-Q1 ideal-diode controller plus an external n-channel MOSFET (Fig. 1) provides reverse-current blocking. When the controller’s EN pin goes high, the MOSFET turns on, minimizing the voltage drop from VBAT to VOUT. Should the controller sense any reverse current, it turns the MOSFET off, and the MOSFET’s body diode blocks the reverse current while still allowing the load to draw forward current, albeit at a higher forward voltage drop.

1. When the LM74700-Q1 ideal-diode controller’s EN pin goes high, the MOSFET turns on, providing a very low voltage drop from VBAT to VOUT.

The LM74700-Q1 supports linear regulation by controlling the MOSFET’s gate voltage based on load current. At high load currents, the gate-source voltage approaches the maximum gate-drive voltage, allowing operation close to the lowest possible RDS(ON) voltage. Related TI devices offer hysteretic ON/OFF control, with the MOSFET fully turned ON or OFF based on defined voltage thresholds.

Automotive EMC Test

Power-system engineers consistently face challenges regarding electromagnetic compatibility (EMC). The automotive industry presents many examples of such challenges, with designers developing automotive front-end power systems for electronic control units (ECUs) operating at 100- to 1,000-W levels.

For EMC test, automotive engineers must comply with standards from such bodies as the International Organization for Standardization (ISO 7637-2 and ISO 16750-2) or the Society of Automotive Engineers (J1113-11), which specify acceptable automotive electrical line transient behavior. In addition, automotive OEMs have their own standards, such as LV 124, drawn up by representatives from Audi AG, BMW AG, Daimler AG, Porsche AG, and Volkswagen AG.

Tests described in LV 124 E-06 (superimposed alternating voltage) and E-10 (short interruption) are difficult to meet with Schottky-diode and p-channel FET-based reverse-battery protection schemes. The LV 124 E-06 test applies a superimposed alternating voltage while the engine is running, requiring an ac peak-to-peak ripple as high as 6 V on a 13.5-V dc battery voltage, swept from 15 Hz to 30 kHz. The LV 124 E-10 test checks whether electronic modules are immune to short interruptions—caused, for example, by bouncing relays—in the battery supply.

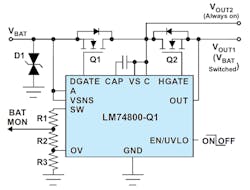

An ideal-diode controller with quick gate turn-on and turn-off time is important to achieving active rectification of a 6-V, 30-kHz peak-to-peak ac input voltage during the E-06 test and meeting class A performance during the E-10 test. To achieve quick gate times in dual back-to-back connected n-FET configurations (which offer inrush-current limiting and overvoltage protection as well as reverse-battery protection), you can employ the LM74800-Q1 ideal-diode controller with integrated dual gate drive.

As shown in Figure 2, the DGATE output drives the first FET (Q1) to replace a Schottky diode for reverse input protection and output-voltage holdup, while the HGATE output drives the second FET (Q2) to realize power-path on and off control, inrush current limiting, and overvoltage protection. A charge pump with a 20-mA peak gate current driver and short turn-on and turn-off delay times ensures a fast transient response, which helps stay within the LV 124 EMC testing limits.

2. The LM74800-Q1 ideal-diode controller features an integrated dual gate drive.

Integrated Ideal Diode

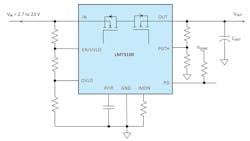

Applications including set-top boxes, smart speakers, handheld power tools and chargers, PCs, notebooks, and retail ePOS (electronic point-of-sale) terminals can benefit from the LM73100 5.5-A integrated ideal diode, which operates from 2.7 V to 23 V and requires no external FET.

Offering integrated analog load-current monitoring and a digital power-good indication with adjustable threshold, the LM73100 (Fig. 3) typically serves power-rail monitoring and protection applications. It also offers adjustable overvoltage and undervoltage protection. On top of that, it can control inrush current and protect against input reverse polarity as well as reverse-current conditions.

3. The LM73100 5.5-A integrated ideal diode operates from 2.7 to 23 V and requires no external FET.

Multiple LM73100 devices can be connected in parallel for higher current applications. In a two-device configuration, one LM73100 turns on initially to control inrush current. When its inrush sequence completes, the first device enables the second device to turn on, and the parallel combination becomes ready to deliver full steady-state current. The LM73100’s 2- × 2-mm quad-flat no-lead (QFN) footprint makes it suitable for space-constrained power ORing applications.

Conclusion

Ideal-diode devices make it possible to replace Schottky diodes or discrete p-channel MOSFET implementations in many applications, offering capabilities such as reverse-polarity protection, reverse-current protection, inrush-current limiting, and overvoltage protection while minimizing losses and real-estate requirements. In addition, they can help you meet EMC test requirements.

Sponsored Resources: