Ultrasonic Metal Welding: Empowering Advances in Battery Tech

Members can download this article in PDF format.

What you’ll learn:

- How ultrasonic metal welding meets the demand for increasingly advanced battery technologies.

- In-depth details of how the ultrasonic metal-welding technology works.

- How ultrasonic metal welding simplifies the assembly of multilayer battery designs.

- The benefits of ultrasonic welding technology in battery assembly.

As demands intensify for superior battery performance, innovative battery technologies continue to advance in remarkable ways to minimize space, maximize power density and storage capacity, as well as extend operating time and capacity. One technology that’s helped usher in such advances over the last 25 years is ultrasonic welding.

Ultrasonic metal welding, which came into broad use around 1990, lends itself extremely well to joining the often thin, fragile, and dissimilar nonferrous materials that are essential to advanced battery designs. These soft, conductive materials include copper, aluminum, nickel, brass, titanium, silver, and even gold. Today, ultrasonically welded connections perform in batteries that power cellphones, laptops, implantable medical devices, electric and hybrid vehicles, military drones, remote-control aircraft and vehicles, and even NASA’s Mars rovers, Spirit and Opportunity.

Benefits of Ultrasonic Metal Welding and Splicing

Ultrasonic metal welding and splicing has many advantages; for instance, working with a wide range of nonferrous materials. It creates a permanent, metallurgical bond between dissimilar metals.

No melting required, which means no change to chemistry or metallurgy of materials. It’s ideal for joining highly conductive alloys where reactivity of materials doesn’t matter. No intermetallic compounds, particulates, or corrosion-causing reactions are created by the process.

This approach handles bonding of thin, fragile metal films and structures and multiple methods of control enable process customization, repeatability, and statistical process control (SPC). The low energy input has 30X lower energy use compared to fusion or resistance welding, plus there are no consumables. Overall, ultrasonic metal welding and splicing has the lowest total cost per weld of any welding technology.

Ultrasonic Welding Is a Low-Energy Process

One of the critical differences between ultrasonic welding and other metal-welding processes, such as resistance or laser welding, is that ultrasonic welding is a comparatively low-energy process—it never melts the materials that are being welded. The melting caused by high-energy welding processes can be essential to joining high-strength ferrous metals. However, melting becomes a problem when it comes to joining softer, nonferrous metals because it leads to the formation of intermetallic compounds that can cause premature material, connection, and battery failures.

Melting copper and aluminum together, for example, would initially produce a connection, but it would eventually result in a galvanic corrosion reaction, causing that connection to fail. Weld-related melting also complicates the successful assembly of the multiple thin foils that must be linked to tabs in modern battery designs.

Basic Principles of Ultrasonic Metal Welding

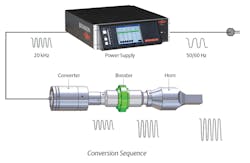

The power supply takes a standard electrical line voltage (typically 50 or 60 Hz) and converts it to the frequency required for metal welding (40 kHz for smaller and/or more delicate parts or 20 kHz for larger, thicker parts). This electrical energy is sent through an RF cable to the converter.

Subsequently, the converter utilizes piezoelectric ceramics to convert the electrical energy to mechanical oscillations at the operating frequency of the power supply. These oscillations are increased or decreased based on the configuration of the booster and horn. The amplitude, or proper degree of oscillation, typically is determined by an application engineer. Precise control of amplitude is essential for repeatable metal welding (Fig. 1).

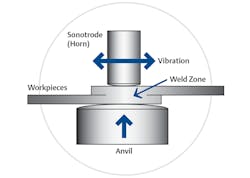

The bonding is accomplished by applying high-frequency vibration to two metal parts that are held under pressure, applied vertically by an air-powered cylinder. The lower metal part is held stationary in a piece of tooling called an anvil, and the upper part is pressed against it while subject to the motion of an oscillating horn, also known as a “sonotrode.” The sonotrode extends horizontally from the power supply of the welder and is the source of the ultrasonic energy that creates the metal-to-metal bond.

When the weld process begins, the upper part is oscillated by the horn against the lower part. Initially, this rapid, oscillating shear force disrupts surface oxidation and contaminants on the adjoining metal surfaces, creating a wide area of metal-to-metal contact. As the oscillation continues, the force breaks down surface asperities (rough areas) on the metal surfaces until a continuous weld area is produced. When the oscillation ceases, the now-welded area is characterized by atomic diffusion across the interface of the joined parts, as the metal surfaces of the welded parts recrystallize into finely grained structures, similar to the structures of cold-worked metals.

The entire process is very rapid, with welds typically completed in a fraction of a second (Fig. 2).

The friction generated by the oscillating shear force of the upper part against the lower creates heat, but not enough heat to melt either of the metals. (Typically, the heat generated equals about one-third to one-half of the absolute melting point of either material.) This solid-state process creates a strong welded bond, yet it avoids burning through thin or fragile foils or melting the materials and forming intermetallic compounds.

A Specialized Process with Precise Control

Ultrasonic metal welding is a specialized process that demands precise control in three main areas:

- Weld energy control

- Weld amplitude control

- Weld tooling quality

Weld energy control

Ultrasonic metal-welding systems offer multiple modes of control over weld quality. They can weld for a fixed length of time (time mode) or weld to a particular finished weld height (height mode), for example. However, welding in energy mode generally provides the best results. This mode, which ensures that each weld receives an identical amount of joining energy, is calculated as follows:

E = P × T

where E equals energy in joules, P equals power in watts, and T equals time in seconds. The watts of power, P, that are consumed in the weld are further broken down as P = F × A, where F equals the downward force exerted on the weld (typically by a pneumatic actuator), and A equals the amplitude of the vibrating shear force directed into the weld.

Thus, when welding in energy mode, an ultrasonic metal welder automatically compensates (using time) for commonly occurring differences in the surface conditions of the metals being joined. Put another way, adjoining metal surfaces with a greater degree of oxidation or contamination will require a longer initial period of “scrubbing” before conductivity is established and effective metal-to-metal joining takes place. Energy-mode welding readily compensates for these differences.

Weld amplitude control

In an ultrasonic metal weld, amplitude refers to the length of the oscillation delivered to the weld zone by the upper, moving metal part. Successful and repeatable ultrasonic metal-weld production demands that this amplitude be carefully calculated based on the materials being assembled. Then it must be precisely controlled throughout the production process using the capabilities of the weld power supply, converter, and sonotrode/horn assembly.

Weld tooling quality

Another major contributing factor in ultrasonic metal-welding success is the design and material composition of weld tooling, particularly the anvil and the sonotrode or horn. The anvil is essential for holding the stationary metal part firmly in place, while the horn must effectively “grip” the moving metal part, precisely delivering the oscillating shear forces through it that will establish the bond.

The ability of the horn to grip the upper part is created through a specialized machining process that produces a pattern of spherical, diamond, or serrated “knurls” (projected ridge-like patterns) on the tip of the horn. These knurls, together with the overall design of the horn, are another essential factor in the ultrasonic metal-welding process.

Critical Connections

Whether individual batteries are Li-ion cylindrical or prismatic types, or newer Li-polymer pouch designs or solid-state, ultrasonic welds are proven and reliable for interconnecting the nickel and copper tabs and foils used as anode and cathode current-collector structures.

Due to the low number of very thin foil structures being joined, welding these or other small battery structures is typically done at a frequency of 40 kHz with low amplitude. In prismatic cells, 40-kHz ultrasonic welding can join up to 20 thin copper or aluminum foils (depends on welding area), simplifying the assembly of multilayer battery designs.

When more than one battery is needed as part of a larger battery module or pack joined by a busbar structure, ultrasonic metal welds also scale up to meet these requirements. Depending on the application, ultrasonic metal welds can join conductive metal components such as battery packs, wire harnesses, and battery cables. For these larger welds, a frequency of 20 kHz with high amplitude is often employed. At this frequency, the welding process can use up to 5,500 W of available power and up to 80 µm of motion (amplitude).

Ultrasonic metal welding with a 20-kHz frequency is typically used on large battery packs for electric cars and battery packs for special vehicles (specialized mining vehicles, large drones, etc.). Depending on the welding area, applications like these might use prismatic batteries that can join foils from up to 100 layers or even more onto a single tab.

Weld Process Documentation for Diverse Global Requirements

In a growing number of industries, device assembly or manufacturing data may be needed to comply with regulations (e.g., unique device identifier requirements for medical devices), meet quality requirements, or support product warranty or service operations. Emerson’s Branson ultrasonic metal welding equipment has the capability to record weld parameters and process data as needed to comply with diverse global requirements.