Using Energy Harvesting to Develop a Self-Powered Sensor

What you’ll learn:

- New energy-harvesting technology developed by TDK is empowering the next generation of smart, battery-free sensors.

- Energy-harvesting technologies maximize the conservation of energy law.

- TDK has created a sensor that operates without the need for a separate power source, yet is able to generate a constant stream of data.

The areas of data collection and power management are both going through significant development. Emerging applications, such as autonomous vehicles, along with the more established IoT, are driving these developments. The phrase “Big Data” refers to the concept that almost anything can be monitored and used to generate data. Analysis turns that data into insights, leading to action.

In the case of autonomous vehicles, the type of sensing used to navigate the vehicle is often perception-based. Specifically, technologies such as LiDAR and radar use a medium, such as light waves or radio waves, to create a field of view. Reflections are interpreted to extract raw data that’s then analyzed.

Many of these sensing modalities experience significant false positives and negatives, thereby creating a potential unsafe outcome under adverse conditions. This abstract way of observing is typical of sensing technologies; practically all sensors work by perceiving their surroundings. Most sensors will need to send the raw data to a host processor for analysis. This creates another level of abstraction, as the raw data will probably be quantized and encoded before being sent.

In the case of tire-pressure measurement systems (TPMS), the sensor may be expected to transmit data on a frequent basis. The TPMS is fitted to the tire's valve, which means the entire assembly needs to be small. This includes the battery, so it may require replacement after short periods.

In the case of vehicles with a high utilization rate, such as taxis or delivery trucks, this means time spent out of service and, therefore, lost revenue. When these vehicles become fully autonomous, they will be in service almost constantly, so any downtime will be expensive.

One way it’s addressed by technology is to reimagine the way data and power coexist. There are numerous examples of innovative ways to deliver power and data together, such as RFID, NFC, Power over Ethernet (PoE), and power-line communications. In addition, research has increased around ways of harvesting energy from sources such as light, heat, and movement. A new technology developed by TDK takes this concept a step further, by combining energy harvesting with sensing to remove the differentiation between power and data.

Energy Harvesting in Sensing Applications

Energy harvesting is an active area of research and development, creating new ways of generating power from latent sources, such as differences in temperature, natural or artificial light, and even vibrations. The fundamental principles are well-established and a growing number of energy-harvesting solutions are able to generate enough power to operate intelligent IoT nodes for short periods of time.

What these existing technologies provide is unstable and largely unpredictable power, primarily intended to be harvested, stabilized, and regulated. At this point, the power no longer resembles its original form. It becomes anonymous, as it will no longer have any trace of how it was generated. That’s to be expected because the basic requirement is to generate simple, useful power.

However, by going through that process, any information that may have been implicit within the shape of the power waveform is lost as well. Any implicit information in the power waveform is discarded because it’s of no interest.

But what if that information wasn’t discarded, and instead turned into valuable data? That describes how the new energy-harvesting technology developed by TDK is being used. This new energy source helps empower the next generation of smart, battery-free sensors. The energy-sensor combination forms a technology that provides key insights without any form of additional power. For edge-based processing and inferencing, this opens up new opportunities.

The technology uses the piezoelectric effect to generate scalable energy, but the real innovation comes from using the shape of the power generated, as well as its energy. The oscillating waveform, which in the demonstration application can reach 70 V pk-pk, carries with it a signature of the stresses exposed to the piezo element. By analyzing that signature, the piezo element also is being used as a high-resolution motion sensor.

EH-Modules

TDK has developed a demonstration platform, called InWheelSense, that incorporates multiple energy-sensor devices, referred to as EH-Modules (energy harvesting). These modules are coupled to a processing hub that includes power-management circuits, which is itself powered by the modules. The demonstrator is designed to be fitted to a wheel, with the hub positioned in the center and the EH-Modules positioned around the wheel’s rim (Fig. 1).

Each EH-Module can generate 1 mW of dc power or 90 mW of burst power every rotation when the vehicle is traveling at a speed of 105 km/h. Unlike other forms of energy harvesting, the EH-Module’s output is also used to provide data about how fast the wheel is rotating; the direction of rotation, slip, wheel imbalance, torque, and fuel analysis; the direction of the vehicle; and even road conditions. Such data can be either stored locally on the IWCM (InWheelSense Control Module) or broadcast in near real-time using Bluetooth Low Energy (BLE) or LoRa radio.

For evaluation purposes, the demonstrator uses five EH-Modules. The outputs of three of the modules are used purely for power, while the outputs of the remaining two are used to generate data.

The Shape of Energy

It’s only through sustained innovation that this new approach to energy harvesting and edge sensing is viable. One of the underlying trends is the way the semiconductor industry is able to continually drive down the power needed to process information, or instructions per watt. This makes it possible to do more with less power, and thus move the intelligence needed to process data closer to the source of that data.

There are two positive results from the development of edge processing: It reduces the amount of data that needs to flow between the network’s nodes and the network’s core (or cloud), and, as a direct result of that, it reduces the latency between sensing raw data and deriving valuable insights. Both features will become more critical as we move closer to the concept of ubiquitous intelligence, such as fully autonomous vehicles.

Another important and related trend is the way artificial intelligence (AI) is moving closer to the network edge. The latter trend is enabled by the former. Building on this, we can expect a rapid development of higher-performance processors with dedicated AI features, which will further accelerate the adoption of edge-based inferencing.

For AI to be truly useful, it requires a steady supply of high-quality, low-latency data. Today, most sensors aren’t designed to provide this level of output, which is partly due to the power requirements involved. By leveraging these trends and adding its own unique scalable energy-harvesting technology, TDK was able to create a sensor that operates without the need for a separate power source, yet can generate a constant stream of data (Fig. 2).

Moving into the Analog Domain

Most sensors now generate digitized data, or data that’s intended to be digitized so it can be processed. This quantization is convenient, in terms of the bandwidth needed to transmit the data or the amount of memory required to store it. What it also does is discard large parts of the data that are deemed irrelevant. That may be because the system is looking for peaks, or excursions beyond predefined limits.

The piezoelectric sensor in the EH-Module is different in this respect. Instead of quantizing the data at the source (in the sensor) and only sending snapshots of what’s actually being detected, the EH-Module sends a constant, analog waveform to the hub.

In part, this is because the sensor data is also the power source for the hub’s electronics, and therefore every part of it is useful. This stream of unfiltered data is a constant analog signal containing huge amounts of useful information. The key is to process it in a way that delivers such value. It can be achieved using anything from a simple microcontroller to a highly parallel multicore processor.

As mentioned earlier, developers are porting AI technology to low-power MCUs to implement edge inferencing. This describes embedding an inferencing model that’s been developed using AI training technology based on huge amounts of data. The model is then pared down and optimized to run on a much smaller and simpler embedded MCU. This technique can be used to run something as complex as a convolutional neural network (CNN) on an ultra-low-power MCU in an application powered by EH-Modules.

A Constant Stream of Data

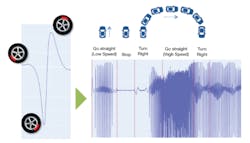

The waveform generated by the EH-Modules changes as the wheel rotates (Fig. 3). This creates a signal that accurately reflects the sensor’s experience. The IWCM developed as part of TDK’s technology demonstrator includes a BLE connection, allowing it to send data to a smartphone or other gateway. The EH-Modules developed as part of the demonstrator feature additional sensors, including an accelerometer, gyroscope, barometric pressure sensor, Hall switch, microphone, particle, and temperature sensor.

All of this sensor data can be wirelessly transmitted by the IWCM to the cloud, where it can be processed to detect road, tire, and weather conditions. These insights then may be used to provide safety features, as well as identify patterns in the way roads are used. The data could also be used to augment traffic-monitoring services.

The same sensors, using the same technology, could be employed in other applications. This might include condition monitoring for large infrastructure, such as railroads, road bridges, or wind turbines.

Conclusion

The idea of free energy has tempted engineering minds since the dawn of time. The concept of energy-free data is much more recent. Energy-harvesting technologies go some way to maximizing the conservation of energy law, but we have yet to realize its full potential. Simplifying the interface between power and data provides an important step in that direction.

The technology developed by TDK takes energy harvesting to the next level. Energy that carries actionable data demonstrates how looking at something from a different perspective can open up new opportunities.