Conductive Polymer Layer Stymies Li-ion Battery Thermal Runaway

What you’ll learn:

- How did polymer current collectors prevent thermal runaway in Li-ion 18650 cells?

- “Operando” (live) high-speed X-ray radiography provided evaluation of nail-penetration abuse experiments.

- Post-mortem 3D X-ray CT presented visual analysis of the cells after abuse.

- Explanation of the mechanism of short-circuit isolation in polymer current collectors.

The quest for safer lithium-ion batteries continues to spur advanced research, especially with concerns about the prospect of thermal runaway, with most cases of thermal runaway traced to an internal short circuit. Such a short generates an increasing amount of heat that can trigger a failure in adjacent batteries and spark fires. The temperature inside the battery has been shown to reach as high as 800°C and higher in just a few seconds.

To further understand the probe, then devise and validate a solution, researchers at the National Renewable Energy Laboratory (NREL) worked with a global team including NASA, University College London, The Faraday Institution in Oxford, National Physical Laboratory in London, and The European Synchrotron in France.

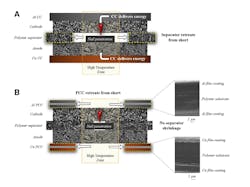

Their approach involved a materials substitution for the current collector in these batteries that conducts electricity to and from the negative and positive terminals. This structural and electrical element is usually made of either aluminum or copper. Instead, the researchers used a polymer current collector (PCC), which is a collector with an inside layer of plastic between the metal (Fig. 1). The PCC was manufactured by Soteria Battery Innovation Group and the custom 18650 batteries (18 mm diameter and 65 mm tall, a widely used, industry-standard size) were made by Coulometrics.

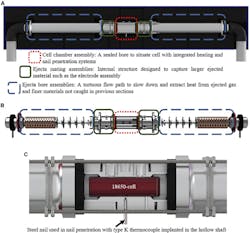

The researchers initiated a controlled and instrumented failure driving a nail into the cells to trigger a short circuit (these aren’t hardware-store nails: each had an embedded Type K thermocouple). The nail penetrated to a depth of 9 mm, an event that took between 1.1 and 1.6 seconds (Fig. 2).

Of course, the problem with “in operando” (live observation) battery testing is two-fold: You have to initiate the failure in a controlled manner and then capture the very high-speed events induced by the failure. The NREL project used high-speed X-ray imaging at 2,000 frames per second (fps) as well as post-failure analysis including additional CT scans and scanning-electron-microscope (SEM) imaging.

They concluded that their use of the PCC was a success. Repeated experiments on multiple batteries demonstrated that adding the PCC in the positive electrode was sufficient in every instance to prevent thermal runaway. The specific runaway-prevention mechanism and associated squelching was that as the temperature increased, the PCC shrank to isolate the nail from the negative terminal and thus shut down the short circuit.

As this is an NREL project, the test arrangement is sophisticated and advanced. The temperature rise and time were captured via their recently developed calorimeter and nail-penetration cell chamber, formally called the Fractional Thermal Runaway Calorimeter (FTRC) (Figure 3 and References 1 and 2).

In addition, the associated documentation is thorough, beginning with their paper “Prevention of lithium-ion battery thermal runaway using polymer-substrate current collectors” published in the journal Cell Reports Physical Science. Other available resources, including their high-speed videos, are cited in the references below, too.

Also of note: In addition to this project and its documentation, NREL just released of its Battery Failure Databank, a compilation of data generated by hundreds of abuse tests (nail penetration, thermal abuse, internal short-circuiting) conducted on lithium-ion batteries. This comprehensive databank provides information on how much heat a battery generates during thermal runaway, as well as hundreds of high-speed radiography videos of internal failure mechanisms—all of which you’d rather have someone else do rather than even try to investigate on your own.

References

1. Electronic Design, “Calorimeter Deliberately Drives Li-Ion Cells into Thermal Runaway and Explosion”

2. NASA, “Enhancing Battery Safety with Fractional Thermal Runaway Calorimetry”(excellent PowerPoint presentation); then click on “View Document” button

3. Cell Reports Physical Science, “Prevention of lithium-ion battery thermal runaway using polymer-substrate current collectors”

4. Cell Reports Physical Science, “Supplemental information”

5. NREL, “Video S1: High-speed (2000 fps) X-ray radiography of cell undergoing nail penetration where thermal runaway is observed”

6. NREL, "Video S2: High-speed (2000 fps) X-ray radiography of cell underdoing nail penetration where thermal runaway was prevented”

7. NREL, Battery Failure Databank