EMI Mitigation on NASA Spacecraft

This article is part of the TechXchange: Delving into EMI, EMC and Noise

Members can download this article in PDF format.

What you'll learn:

- Testing capabilities at NASA's Glenn Research Center.

- EMI on the ISS and a power filter to help minimize it.

- Dealing with EMI on the Mars Rover and CubeSats.

Electromagnetic interference (EMI) can be a nuisance and even approach disastrous levels in outer space. NASA engineers take every precaution to verify any kind of flight hardware that goes into space.

NASA Glenn Research Center

An EMI laboratory at NASA’s Glenn Research Center (GRC) located on the outskirts of Cleveland, Ohio, is dedicated to creating technologies that will propel us into the new millennium for space travel. This lab features many electromagnetic-compatibility (EMC) services, including EMC hardware design to meet necessary requirements in space. The lab also offers consultation during the design and development of various space systems.

The Space Power Facility (SPF) at GRC has the world’s largest thermal-vacuum test chamber that can qualify space vehicles and equipment for outer-space conditions. This interior aluminum vacuum chamber is actually a large, and electrically complex, RF cavity that has excellent reverberant RF characteristics. This is also the world’s largest EMI/EMC test facility

Testing at this lab includes intermediate testing as a specific design progresses along. It also tests for shielding effectiveness, filtering, and proper grounding, leading to final qualification tests for experiments in flight. This lab even provides testing at customer locations for items far larger to fit into the GRC EMI lab shielded room (Fig. 1).

The SPF chamber is presently testing EMI radiated susceptibility of the crew module for the Orion spacecraft, which will ultimately go to Mars.

EMI on the International Space Station (ISS)

Back in the Space Shuttle program, the contact potential between the ISS and the Space Shuttle had been monitored on all docking missions. Langmuir probes, mounted on the ISS, had monitored contact potential between the ISS and any docking vehicle. No serious EMI effects were ever noted on any ISS or Space Shuttle equipment after docking (Fig. 2).

NASA also published “Analysis of Radiated EMI from ESD events caused by Space Charging.” This effort used modeling to analyze conducted and radiated EMI caused by electrostatic-discharge (ESD) events in space. NASA engineers looked at surface charging, which could develop on the exterior of satellite surfaces, due to the interaction between those surfaces and the space plasma environment. NASA’s extensive research assessed charging mechanisms present when dielectric surfaces of any spacecraft become exposed to the space plasma environment, usually at geosynchronous Earth orbit (GEO) and POLAR orbits.

When ESD happens, stored charges are released. These create a discharge current that may generate conducted emissions, which happen when a replacement current originating as a charge is blown off a dielectric surface. This induces a replacement current flowing from a satellite or spacecraft structure.

Radiated emissions are generated by the ESD current pulse. When a rapid surface potential changes, the effect is noise induced in circuitry via capacitive coupling. Also, discharge currents can inductively induce a signal into a victim circuit. These inductive, capacitive, and field-to-circuit couplings are manifestations of transient radiated and conducted EMI.

ISS Power Filter Design for Conducted Emissions

Power-line conducted emissions also need to be controlled on the ISS to protect power quality, limit electric-field radiation, and control noise currents on vehicle structures. Because the ISS doesn’t use the radio-frequency (RF) spectrum below 100 MHz, there are no radiated emissions limits imposed on payloads below that frequency.

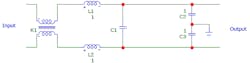

A manufacturer-designed filter (Fig. 3), prior to the publication of MIL-STD-461D, had a test source impedance using 10-mF feed-through capacitors. This filter is known as the 461B filter.

The filter design shown in Figure 4 came after the publication of MIL-STD-461D, where the source impedance had two 50-mH line impedance stabilization networks (LISNs). This filter is known as the 461D filter, which had both Y (line-to-ground) capacitors (C5 and C6) and an X (line-to-line) capacitor (C4) as its first elements, providing a mismatch with the high source impedance.

Mars Rover EMI

Power-conversion architectures on the Mars Rover include isolated dc-dc converters, point-of-load dc-dc converters, and EMI filters that power the camera system and processing on the Mars 2020 Rover.

Just about all of the data collected by NASA Mars Rovers returns to Earth through a relay link from the Mars surface to a Mars Reconnaissance Orbiter circling Mars. All of this science data comes from omnidirectional antennas for simplicity. However, this system is quite susceptible to RF interference coming from nearby science payloads and spacecraft subsystems, which downgrades link performance by a factor of 2+.

Most of the interference generates from Fourier overtones via switching power supplies, data lines, stepper motors, and clocks. This EMI on the spacecraft is pretty stable in frequency; however, the EMI tones’ complements will vary as the spacecraft operating mode changes.

An Adaptive EMI Mitigation study has developed computationally efficient algorithms that enable characterization and elimination of major tone interference. Such interference would degrade the data return performance from the Rover on the Mars surface to the relay orbiters overhead.

CubeSat Antenna EMI

Designing a monopole wire antenna is pretty simple for communication use on a CubeSat. A wire needs to be cut to a quarter-wavelength and a perpendicular half-wavelength ground plane must be created.

A 17.5-cm monopole is best for the CubeSat and will need a 35-cm ground plane formed by a parallel satellite surface. This ground plane would be too large for a CubeSat, so designers have to tune that wire antenna by cutting off small lengths until a desired return loss is achieved (monopole antennas can be very forgiving in reaching a desired return loss).

The perpendicular half-wavelength ground plane, which can be built using satellite external panels, needs to be constructed to provide electrical connectivity. Because RF current will flow through these panels, designers can expect a higher level of EMI influencing internal and external electronics for satellite operations. This influence will be most prevalent during transmission and will make sensor readings and bus voltages (especially I2C bus) unreliable. This may also affect transmitter electronics as well as microcontroller control of the transmitter. Installing proper electromagnetic shielding in place will help mitigate these effects.

Using a dipole antenna for the UHF band will provide overall better performance. However, the EMI problems will still exist if shielding isn’t properly applied.

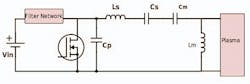

CubeSats also may have an RF power supply to drive an electrothermal plasma micro-thruster. One example of such a power supply could be a 13.8-MHz, 14-V-input, 15-W design using air core inductors (Fig. 5).

Air-core inductors are perfect for operation in a harsh environment because they don’t use magnetic cores, thus saving space. Faraday shielding is usually added to minimize radiated EMI. Conducted EMI may be minimized via a multi-resonant input filter using PCB inductors. Reference 5 goes into much greater detail for designers.

Summary

All of the vehicles that NASA sends into space must undergo extensive EMI testing. Many of the vehicles are huge while some are much smaller, but all of these electronic systems require testing in the environment in which they will operate—the cold vacuum void of outer space. NASA has constructed such test facilities to simulate this environment at their Glenn Research Center.

The space vehicles greatly vary in size from small satellites and CubeSats to vehicles such as the Mars Rover and other large launch vehicles. All of these spacecraft have electronic devices that need to operate properly in space with a very low failure rate.

Human life, of course, must be protected against any catastrophic failures that may be caused by EMI as the prime objective. The secondary objective is to protect the very expensive space vehicles against failures due to EMI radiation from electronics within these vehicles, as well as any possible EMI from spacecraft docking with other spacecraft. NASA has been very successful in these efforts.

Read more articles in the TechXchange: Delving into EMI, EMC and Noise

References

1. Electromagnetic Interference Laboratory, Glenn Research Center, NASA

2. EMI from Spacecraft Docking Systems, NASA

3. Electromagnetic Compatibility Considerations for International Space Station Payload Developers, NASA Marshall Space Flight Center

4. Analysis of Radiated EMI from ESD events caused by Space Charging, NASA

5. A compact RF power inverter with reduced EMI for a CubeSat electrothermal micro-thruster, IEEE Xplore 2017