EMI Shielding for Drones and UAVs

This article is part of the TechXchange: Delving into EMI, EMC and Noise

Members can download this article in PDF format.

What you'll learn:

- Magnetic EMI fields that affect drones/UAVs.

- Different shielding solutions for EMI/EMR.

- Types of flexible EMI shielding.

Most drones and unmanned aerial vehicles (UAVs) rely heavily on seamless communication from ground systems. Cell-phone towers, buildings and large metal structures, high-voltage power lines, and a high concentration of Wi-Fi networks in an area can cause serious electromagnetic interference (EMI) in drone performance.

EMI effects on drone operations are unpredictable. They can severely disrupt a drone’s navigation system by shifting the drone’s compass out of alignment. When flying close to large structures, EMI can degrade the quality of GPS reception of a drone. It also may disrupt the communication between a drone and its controller.

There’s a growing trend toward drones/UAVs being used to inspect utility areas such as electrical power grids and pipelines. Infrastructure like cell towers also need visual inspection. This is far less costly than a “truck roll” to a site.

A dilemma occurs when a cell-tower antenna is being visually examined by a drone/UAV. The cell-tower transmitting antennas can easily exceed the interference threshold for these aircraft. Usually the drone/UAV will return to its home base when sensing a high EMI signal.

Often, larger drones have an exterior fuselage made from a light metal or a thin aluminum foil to help prevent lightning-strike EMI damage.

This article will take a look into various types of EMI fields and some solutions to mitigate those fields to prevent failures in drone performance.

Magnetic EMI Fields Affecting Drones with Onboard WPT Systems

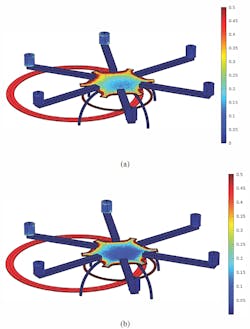

Drone chassis are typically designed with non-metallic materials to reduce the weight and size of the aircraft. Wireless power transfer (WPT) has kilohertz-frequency magnetic fields that can easily penetrate the drone body and disturb internal drone electronics. One good example of such drones with WPT is the DJI F550 drone (Fig. 1).

Three test cases for EMI were examined:

- Test case #1 had the coupled coils in free space

- Test case #2 showed that the performance of magnetic coupling to wirelessly charge the drone had poorer coupling performance due to the copper PCB. This case had a lateral misalignment of the coils equal to 200 mm.

- Magnetic shielding was employed in test case #3, which reduced any coupling problems. The system performed close to coupled coils in free space (just like test case #1). This case had a lateral misalignment of the coils equal to 200 mm (Fig. 2).

Calibrating Drone/UAV Compass Far from EMI Sources

Calibration of a drone/UAV compass will play a key role in accurate navigation. Ideally, a drone/UAV compass should be calibrated according to the Earth’s magnetic field and free from the influence of external fields. Compass calibration should be performed away from any potential sources of EMI.

In addition, users need to be sure to calibrate the compass away from urban areas. Be away from powerlines, steel girders, or rebar embedded in concrete. An open field with minimal man-made structures will work best. Finally, users must also keep mobile devices away from the drone/UAV while doing the calibration.

EMI in UAVs

Designers should be aware of testing methods for EMI/EMC susceptibility. UAV exposure to EMI/EMC is fairly unknown and could range from non-existent to over 10,000 V per meter if they fly too close to power lines. Traditional aircraft have several levels of EMI/EMC protection from the individual line replaceable units (LRUs) to the overall fuselage. Commercial UAVs will typically have minimal ability to filter out radiated noise. The true challenge for design engineers, though, is that while they’re typically trained on the EMI test method, oftentimes that’s not the case when it comes to critical low-cost design methods to avoid EMI susceptibility.

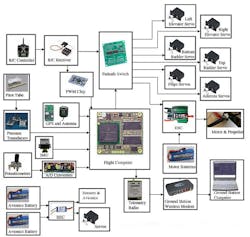

A plethora of electronic components reside in a commercial UAV. The wide variety of components in the UAV provide plenty of opportunities for failure from EMI sources both internal and external (Fig. 3).

EMR/EMI Shielding Solutions

Electromagnetic radiation (EMR) needs to be directed to a particular safe area of a Wi-Fi system, and then absorbed, with the use of proper coatings that can enhance the performance of Wi-Fi in the presence of this EMI. There are three interactive components of EMI emission: the transmitter and receiver sources of electromagnetic energy, and the path for propagating this energy.

We can separate EMI shielding into four entities depending on the frequency range and whether it’s continuous or pulse:

- EMI power spectrum shielding, which is for the range 1 to 100 kHz.

- EMI shielding is the radio frequency range 100 kHz to 1 GHz.

- The microwave, and beyond, frequency band of the electromagnetic energy.

- The electromagnetic pulse (EMP), which has a broad frequency band with high-intensity short-duration bursts of electromagnetic energy, such as in a nuclear explosion or an electric discharge.

The Internet of Things (IoT) is becoming more present in our everyday activities, from mobile phones to smart homes and even autonomous cars. Now even the ubiquitous applications for drones are beginning to feel the disruptive effects of EMI in IoT applications based on the information received by their sensors.

Embedding the sensor node into a viable case to protect against electromagnetic attacks is a solution that needs some research. A better way to implement this, especially in areas such as drones, which need low weight and small size, is to implement electromagnetic shielding to reduce the electromagnetic field (EMF) and protect sensor nodes from interference.

Designers need to reduce EMF radiation levels from the equipment they’re designing as well as mitigate sources of external disturbances to immunize their design.

A shielding effectiveness (SE) parameter describes the performance of the chosen solution and is the most important parameter in electromagnetic shielding materials. The IEEE has a standard for this known as IEEE 299-2006: IEEE Standard Method for Measuring the effectiveness of electromagnetic shielding enclosures.

Flexible EMI Shielding

Shielding layer or layers of Polyaniline (PAni)

PAni and other intrinsic conducting polymer (ICP) materials show potential to replace metal and carbon-based technologies. These flexible materials provide a lightweight, thin layer of coating to mobile-phone and Wi-Fi devices for EMI shielding and have achieved a variety of S21 shielding values. Drones and UAVs will greatly benefit from this lightweight, flexible material.

Electrically conductive EMI gaskets

Gaskets will be needed when there are imperfect mating surfaces. For EMI reduction, gaskets must be electrically conductive and flexible.

In more highly conductive gasket materials, there will likely be more susceptibility to oxidation due to the hardness of the oxides. Some oxide layers will remain thin, while others can build up in thickness quickly. This buildup forms an insulation between the gasket and flanges, but that can be overcome by using slow-oxidizing materials or coatings, like nickel, tin, or zinc.

Such EMI gaskets include metal beryllium-copper (BeCu) spring fingers, mesh gaskets, elastomeric gaskets filled with plated metal fillers, and electrically conductive caulks and sealants.

Summary

EMI can wreak havoc on flying drones and UAVs. Cell-phone towers and cell phones are ubiquitous and often are powerful sources of EMI to drones and UAVs. So how does this happen if cell phones operate at 1.9 GHz? Intermodulation is usually the primary culprit here. High-voltage lines also may interfere with drone/UAV operation. High concentrations of Wi-Fi equipment can be offenders as well. And finally, buildings and large metal structures may reflect EMI sources.

Fear not, valid solutions mentioned in this article will thwart any EMI intrusions on drones and UAVs. Careful drone/UAV design can prevent flight control errors. Even more powerful, potentially catastrophic EMI offenders can be reflected away from sensitive drone/UAV surfaces with the right design techniques discussed here.

Read more articles in the TechXchange: Delving into EMI, EMC and Noise

References

- Magnetic Field Levels in Drones Equipped with Wireless Power Transfer Technology, IEEE Xplore

- Modelling of Intrinsic Conducting Polymer for Wi-Fi Electromagnetic Interference Shielding, Science and Information Conference 2013 October 7-9, 2013 | London, UK

- EMI/EMC and Co-existence analyses of digital and RF wireless interfaces on consumer and mobile products, IEEE Xplore

- Low EMF Three Phase Resonant Magnetic Field Charger for Drone with High Q Reactive Loop Shielding, IEEE Xplore

- Improving UAV Reliability, DfR Solutions

- Flying Your Drone in Urban Areas with Heavy Signal Interference, Pilot institute

- Electromagnetic interference shielding in unmanned aerial vehicle against lightning strike, TELKOMNIKA, Vol.17, No.2, April 2019, pp. 915-919