Members can download this article in PDF format.

Battery-powered smart flow meters must record information such as gas or water consumption and periodically transmit that information to a data center, often using NB-IoT. And line-powered IoT devices may require backup power to communicate their status during rare system power outages. For both use cases, a bidirectional buck/boost converter combined with a supercapacitor can supply the high peak pulse currents needed to complete the data transmission.

Smart Flow Meters

Most smart flow meters, designed to operate over a 10- or 20-year lifetime, employ LiMnO2 or LiSOCl2 batteries. Because the LiSOCl2 features a higher output voltage (3.6 V vs. 2 to 3 V for the LiMnO2), it can better support 3-V electromagnetic valve control and has become the popular choice for smart-meter applications.

However, LiSOCl2 batteries offer limited pulse-current capability, and high load currents significantly degrade their capacities. For example, one specific LiSOCl2 battery operating at 20°C with a 200-mA load current would suffer capacity degradation of 40% compared to the same battery operating at a load current of only 10 mA. The degradation can be even more pronounced at lower temperatures.

One method to reducing this degradation is to place a hybrid layer capacitor (HLC) in parallel with the battery, with the HLC providing much of the peak current that might be needed for NB-IoT data transmission. This approach, however, provides no way to directly control the battery current, which could very easily reach a level that degrades capacity.

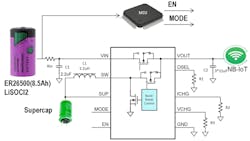

An alternative is to use a supercapacitor like Texas Instruments’ TPS61094, a 60-nA quiescent-current bidirectional buck/boost converter with a bypass mode. Working in buck mode, the TPS61094 can charge the supercapacitor at a charging rate set by an external resistor and to a voltage level set by another external resistor (R2 and R3, respectively, in Figure 1). Limiting the supercapacitor’s voltage to 2 V minimizes capacitor leakage current and extends lifetime.

In boost mode, the TPS61094 can boost and regulate the supercapacitor’s output to a voltage level set by R1. The TPS61094 doesn’t require MCU intervention—it can automatically switch between the buck and boost modes. Adding a series resistor (Rin) of about 40 Ω between the battery and the TPS61094’s VIN pin helps limit the battery discharge current during data transmission.

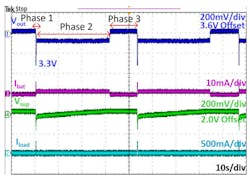

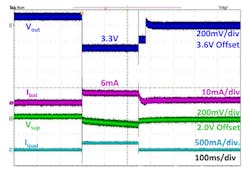

Figure 2 displays test waveforms using a 10-s/div timebase for the Figure 1 circuit driving an NB-IoT transmitter. Data transmission occurs in phase 1, where load current reaches about 250 mA for 250 ms (Fig. 3), which zooms in on phase 1 using a 100-ms/div timebase. The TPS61094 prevents the output voltage from dropping below 3.3 V and limits battery current to about 5 or 6 mA (depending on temperature), thereby assuring minimal battery-capacity degradation.

In phase 2, data transmission stops, and the TPS61094 charges the supercapacitor with a current of about 2.5 mA. Phase 3 begins when the capacitor reaches its 2-V threshold and charging stops. Phase 3 is a standby mode, in which the system waits for the next NB-IoT transmission.

Consider a flow meter’s standby-mode current drain in more detail. Standby mode consumes 5 to 10 mA of quiescent current (IQ) primarily for metrology, microcontroller, and protection circuitry. Although IQ’s absolute value is very low, it’s the main contributor to battery drain over the meter’s lifetime due to the very short durations of the transmit and charging modes. To keep that lifetime as long as possible, the IQ of any connected converter such as the TPS61094 should be in the tens-of-nanoamperes range.

For flow meters, maximizing the usable battery capacity offers several advantages. For a specific battery, the TPS61094 and supercapacitor combination will allow more frequent data transmissions or longer total operating lifetime. For applications not requiring more transmissions or longer lifetimes, it will allow the use of a smaller battery.

IoT Line-Power Backup

In addition to battery-powered flow meters, the TPS61094 and supercapacitor combination can support many IoT devices, including those that run from line power but need backup power in case of an unexpected outage. The backup power can allow the devices to shut down safely or communicate that a power failure has occurred.

A smart electric meter, for example, could transmit details about the time, location, and duration of an outage via an RF interface such as NB-IoT. An effective backup implementation transitions seamlessly between normal and backup operation and can operate through repeated outages without maintenance.

A representative circuit for implementing this backup function is like the one shown in Figure 1, but with a 5-V dc system power-rail voltage replacing the battery. When system power turns on, it powers VOUT directly through the TPS61094’s bypass FET. At the same time, the TPS61094 enters buck mode, in which it charges the supercapacitor with 500 mA of constant current. Charging stops when the voltage across the supercapacitor reaches 2.5 V, and the system power continues to power VOUT. When an outage occurs, the TPS61094 turns off its bypass FET and enters boost mode to use energy stored in the supercapacitor to deliver power to VOUT.

Conclusion

You can extend a smart flow meter’s battery life by employing a low-leakage power buffer, such as TI’s TPS61094, to limit the battery peak current to 10 mA to minimize battery-capacity degradation. A supercapacitor is able to help meet peak current demands. For line-powered IoT devices, the TPS61094 and supercapacitor combination can provide backup power during outages.