Power-Supply Subsystems for PPG Remote-Patient Vital Sign Monitors (Part 2)

This article is part of TechXchange: Power Supply Design series: Power-Supply Subsystems for Remote PPG Vital Sign Monitors

Members can download this article in PDF format.

What you’ll learn:

- Learn how to select a power-supply configuration based on PPG system requirements.

- Review the implementation of switched-mode power-supply reference circuits for both discrete (Part 1) and integrated designs (Part 2).

- See a power-supply performance test methodology that validates the system over different device use cases and transient loading conditions.

- Get a checklist to validate the implementation.

- Gain troubleshooting knowledge to address implementation issues.

A photoplethysmogram (PPG) device can be implemented to measure blood-volume changes from which vital sign information such as blood oxygen levels and heart rates are derived. In Part 1, we provided discrete power-supply circuit design solutions for best performance using the MAX86171 optical pulse oximeter and heart-rate sensor analog front end (AFE). In Part 2, we show an integrated solution for space-constrained applications using the MAX86141 optical pulse oximeter and heart-rate sensor AFE (can be used with the MAX86171 as well).

As mentioned in Part 1, Analog Devices offers power-supply subsystem circuit designs that have been pre-validated (i.e., designed, built, and tested), ensuring the signal-to-noise ratio (SNR) performance of each biosensing AFE device.

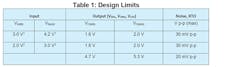

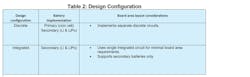

To reiterate, below are details for the power-supply circuits with each example being complemented with a validation checklist and troubleshooting guide to aid circuit designers, if needed. Figure 1 shows a standard power block diagram encountered in many remote patient monitoring applications. Table 1 reveals the design limits, and Table 2 shows the design considerations for discrete and integrated solutions.

Integrated Design Description

This dc-dc power-management integrated-circuit (PMIC) design is used to regulate three output power-supply rails for use in a remote-patient vital sign monitor subsystem. The IC features a single-inductor multiple-output (SIMO) buck-boost regulator that provides the power rails from a single inductor to minimize total solution size while maintaining high efficiency.

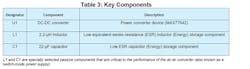

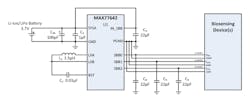

This circuit delivers proper line and load regulation while maintaining low output noise levels needed to preserve biosensor SNR performance which is powered by a rechargeable lithium-polymer battery. Figure 2 shows the PPG subsystem using an integrated power supply device and Table 3 lists the main components.

1.8-V/1.8-V/5.0-V SMPS Circuit Using a PMIC

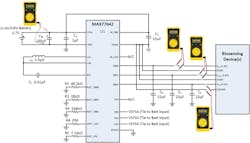

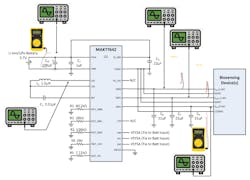

The following circuit based on the MAX77642 PMIC shows typical input and output power-supply levels for a properly operating switched-mode power-supply (SMPS) device in remote patient vital sign monitor applications. A digital multimeter (DMM) can be used to probe the input and output ports to validate the supply voltage levels (Fig. 3). The power-supply output levels can vary due to various factors such as a discharging battery or changing loads (i.e., device mode changes, devices waking up from sleep mode, etc.).

Integrated 1.8V/1.8V/5.0V SMPS and Circuit Validation Checklist

Figure 4 shows the integrated MAX77642 PMIC for remote-patient vital sign monitoring.

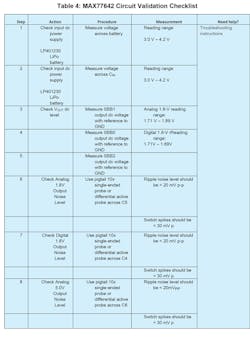

Table 4 can be used as a checklist to validate operation of the 1.8-V/1.8-V/5.0-V SMPS circuit using the MAX77642 device while connected to a biosensing circuit load.

1.8-V/1.8-V/5.0-V SMPS Circuit Troubleshooting Guide

The following circuit troubleshooting instructions (Fig. 5) will help designers if operational issues arise with operation of the 1.8-V/1.8-V/5.0-V SMPS circuit. This guide addresses the most common problems that arise in implementing these integrated switch-mode power supplies.

Troubleshooting the MAX77642 SMPS Circuit

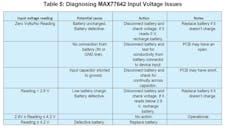

Step 1: Check the input voltage

Using a DMM with an internal impedance of 1 MΩ or larger (e.g., Fluke 87), measure the voltage across at the input to the MAX77642 device. Be sure to connect the negative “black” lead to the ground and the positive “red” lead to the input “IN” pin of the device. If the input pin isn’t easily accessible, place the leads across the input capacitor (CIN).

Use Table 5 to diagnose and fix associated problems.

Step 2: Check the inductor signal waveform

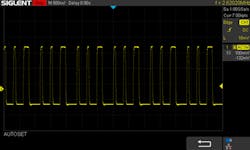

Using an oscilloscope or digital storage scope (DSO), probe the LXA pin on the MAX77642 device. If the input pin isn’t easily assessable, place the probe on the (LXA) inductor end cap. Note: It’s recommended that the oscilloscope and probes have a minimum bandwidth of 200 MHz.

If the circuit is operating correctly, the waveform should be a series of pulse waves with minimal ringing on the rise and falling edges (Fig. 6).

The pulse waveforms demonstrate the time multiplexing of three SMPS sharing a single inductor (also known as SIMO power supply).

Deviations from the ideal series of pulse waves can be used to effectively diagnose and fix many problems. Use Table 6 to diagnose and fix associated problems.

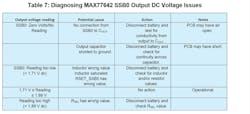

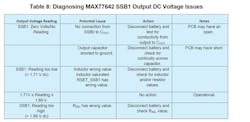

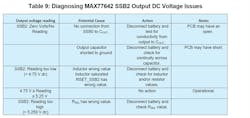

Step 3A: Check the output dc voltage

Using a DMM with an internal impedance of 1 MΩ or larger (e.g., Fluke 87), measure the voltage at the three outputs of the MAX77642 device. Be sure to connect the negative “black” lead to the ground and the positive “red” lead to the associated SSBx channel output “OUT” pin of the device. If the output pin isn’t easily accessible, place the leads across the associated output capacitor (COUT).

Use Tables 7, 8, and 9 to diagnose and fix associated SSB0 (1.8 V dc), SSB1 (1.8 V dc), and SSB2 (5.0 V dc) output problems, respectively.

Step 3B: Check the output ac voltage

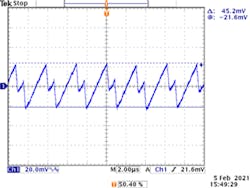

Using an oscilloscope or DSO, now measure the output ripple (ac) by probing the three outputs of the MAX77642 device. It’s recommended to use a differential technique to properly measure the output and avoid RF pickup. Note: It’s recommended that the oscilloscope and probes have a minimum bandwidth of 200 MHz.

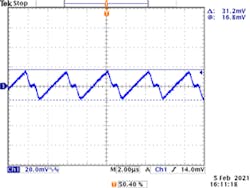

If the circuit is operating correctly, the SSB0 waveform should be a 1.8-V dc (digital) output with a small ripple waveform superimposed on it. Figure 7 shows the ripple waveform.

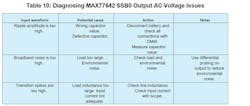

Use Table 10 to diagnose and fix associated problems.

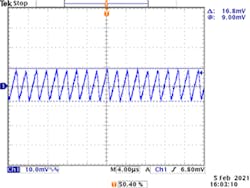

If the circuit is operating correctly, the SSB1 waveform should be a 1.8-V dc (analog) output with a small ripple waveform superimposed on it. Figure 8 shows the ripple waveform.

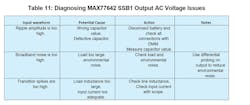

Use Table 11 to diagnose and fix associated problems.

If the circuit is operating correctly, the SSB2 waveform should be a 5.0-V dc (for LEDs) output with a small ripple waveform superimposed on it. Figure 9 shows the ripple waveform.

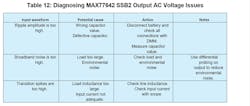

Use Table 12 to diagnose and fix associated problems.

Conclusion

This concludes the two-part series that presented pre-validated power supply circuits, both discrete and integrated, for use with the MAX86171-based and MAX86141-based PPG remote-patient vital sign monitors. While both the integrated and discrete switch-mode power-circuit designs support PPG performance, the integrated solution offers a smaller footprint and reduced part count and is recommended for size-constrained applications.

The corresponding validation test data for both discrete and integrated power-supply implementations can be found on the Maxim Integrated, now part of Analog Devices, website at “Power Supply Subsystems for Remote Patient Vital Sign Monitors.”