Mitigate EMI in Your 400-Hz Systems

This article is part of the TechXchange: Delving into EMI, EMC and Noise

Members can download this article in PDF format.

What you'll learn:

- What led to the 400-Hz generator as the answer for aviation power?

- Challenges with EMI filters.

- Topology for a 5-kW power supply targeting aircraft applications.

Modern aircraft electrical systems use a variety of ac and dc power voltages/currents. The most common voltage and frequency is 400 V ac @ 400 Hz, 115 V ac @ 400 Hz, and 28 V dc. In this article, we’ll primarily discuss 400-Hz ac and its effect on neighboring electronic systems.

Why Does Aviation Use 400-Hz Power?

When aviation began using electrical systems years ago, the industry chose dc power. When ac later became more prevalent in aircraft, the primary goal was reducing the size and weight of transformers, motors, and power supplies. Designers later opted to use a higher frequency, which would lead to lighter-weight components.

At this higher frequency, more power would be lost in the transmission lines, which would also increase cost. (The two key properties here are dielectric conductance and copper resistance that cause signal loss at high frequency; this is because they vary with frequency.) However, the length of power transmission systems within the aircraft was short, so the power loss became negligent.

Power engineers ultimately designed a unique generator that created the 400-Hz output used today. This allowed an original motor, which was fairly large and heavy, to be replaced by a far smaller and lighter version that could perform the same work. The reduced weight enabled an increase in cargo capacity and trimmed-down fuel consumption.

It was then that power at 400 Hz for aviation became successful and was ultimately used as the standard of modern ac-powered aircraft. Airports worldwide quickly standardized on this 400-Hz power system, which had a cable and plug that enabled the aircraft to land at any area of the globe to receive proper service.

400-Hz EMI Filters

The 400-Hz operating frequency creates a significant challenge for EMI filters. The main drawbacks are high leakage current and increased magnetic core losses, which will lead to heating in both inductors and capacitors. Eventually, this could cause filter failure.

In these 400-Hz applications, designers must be sure that the EMI filter will operate safely. Plenty of existing commercial filter reference designs can operate well at 400 Hz.

How can designers meet the CE101 conducted emissions to meet MIL-STD-461G? This standard has applications from 30 Hz to 10 kHz for power leads, which also includes power returns. Their power comes from other sources that aren’t part of the Equipment Under Test (EUT) in surface ships, submarines, Army aircraft (including flight line aircraft), and Navy aircraft.

The main difficulty in meeting the standard will be the low frequency content of the noise signals. Usually, the 3rd, 5th, and 7th harmonics will be the problem frequencies. So, for 400 Hz power, designers must be able to attenuate the 1,200-, 2,000-, and 2,800-Hz harmonics.

The modern aircraft power industry is moving toward the realization of the More Electric Aircraft (MEA), an all-electric aircraft. To enable MEA, it will be important to have high power density and efficient power-conversion solutions. Besides high efficiency and power density, it will be critical for power converters to comply with strict military electromagnetic-interference (EMI) standards for the MEA.

A 400-Hz Aircraft Power Supply

How does one design a 5-kW power supply for aircraft applications? A boost power-factor-correction topology, the Delta rectifier, will comply with military standards for conducted emissions (CE). The design has a front-end rectifier for a 400-Hz mains power supply. For isolation and output dc voltage regulation, a full-bridge dc-dc converter that has a 99% efficiency, along with a high-frequency transformer, could be designed (see Reference 7).

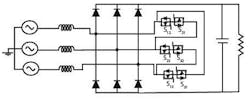

In this topology, the 3rd-harmonic injection switches are connected in a delta configuration (Fig. 1).

The Isolated DC-DC Converter

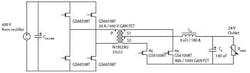

There are two converter types—resonant and non-resonant—for high-power-density dc-dc converters. Resonant converters, like LLC architectures, are usually selected because of their very high switching frequency with soft switching. But since high-power-density, high-current transformers usually operate at a far lower switching frequency, the non-resonant dc-dc converter architecture was selected (Fig. 2).

Summary

Aircraft systems chose a 400-Hz frequency based upon two key parameters: mass and volume. Transformers and rotating machines, running at a higher frequency, led to reduced volume and mass.

Furthermore, a changing ac voltage led to an advantage of using transformers to change the voltage. High voltage with low current would now be able to travel longer distances over a smaller wire, and then become transformed to a safe, lower voltage for power distribution.

Read more articles in the TechXchange: Delving into EMI, EMC and Noise

References

1. “EMC Question for 400Hz Power System,”EMC Standards.

2. “Why Do EMI Filters Fail?,” Astrodyne TDI.

3. “EMC Question for 400Hz Power System,” Interference Technology.

4. “New Considerations in the Input Filter Design of a Three-Phase Buck-Type PWM Rectifier for Aircraft Applications,” IEEE 2011.

5. “THD and EMI Performance Study of Foil-Wound Inductor of LCL Filter for High Power Density Converter,” 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia).

6. EMI 400Hz power sys a682005-214.pdf, International Journal of Circuits, Systems and Signal Processing, Volume 9, 2015.

7. “Power Supply Design Considerations For 400Hz Aircraft Applications,” EPE'20 ECCE Europe.