This Week in PowerBites: Battling BLDCs and a Profusion of Power Tools

This article is part of the This Week in PowerBites Library Series.

A Big Step Forward for Electric Aircraft

Electric aviation took a significant step toward commercial success with BETA Aviation's 1390-mile test flight of its Alia eVTOL technology demonstrator. The aircraft required only 12 hours of flight time and eight stops to recharge the aircraft’s batteries during its journey between Plattsburgh International Airport (KPBG) in New York and Bentonville Municipal Airport (KVBT) in Arkansas.

In keeping with the company's strategy of incremental development, the aircraft flew the trip configured as a conventional airplane, without the previously demonstrated vertical lift rotor system that will be incorporated into the production unit.

The production aircraft, the Alia-250, anticipated to enter service in 2024, is expected to closely resemble the prototype but with a maximum range of 200-250 nautical miles. It will be available configured as either a six-person air taxi or a cargo transport with a capacity of roughly 1400 lbs/200 ft3.

Since Electronic Design's April 2021 story about Alia achieving the first airworthiness approval for a crewed electric aircraft by the U.S. Air Force's Agility Prime Program, Beta Alia 250 is expected to enter service in 2024.

Initial customers include express delivery group UPS and operators serving the Blade Urban Air Mobility service. Development is being funded in part by United Therapeutics, a biotech startup that hopes to use the aircraft's unique capabilities to rapidly transport the synthetic organs it’s developing between existing air freight terminals and hospitals.

Additional juicy details on the Alia and its demonstration flight can be found in an excellent article recently published by Flying Magazine.

Department of Wireless Education: Overcoming the Limits of Inductive Power Transfer

"Taking Position-Free Wireless Power to the Next Level" is an informative article from Eggtronic that discusses some of the solutions being explored to overcome the power, distance, and orientation limitations of inductive power-transfer systems, such as Qi technology.

Topics include:

- Comparing inductive and capacitive wireless power transfer.

- What is the EDEN wireless-power-transfer technology?

- Future plans for EDEN based on simulations and prototypes.

Click here to download the .pdf document.

Power-Supply Controller Slashes BOM Costs, Boosts Efficiency, Plus Other Environmental Benefits

The ST-ONE, STMicroelectronics' latest power-supply controller, was designed to provide extremely high energy efficiency and power density (1.8 W/cc3) and reduce the quantity of plastics required to manufacture ac-dc adapters for USB-PD 3.1-compliant consumer products. Its support resources include the EVLONE65W reference design for a 65-W USB-C adapter that has the same size and weight (less than 70 g in a 37-cm3 housing) as a standard 20-W smartphone charger.

ST-ONE is optimized for designs based on non-complementary active-clamp-flyback topologies, such as the quasi-resonant flyback scheme, which recovers switching energy that would normally be lost in conventional circuits.

The IC contains all of the peripherals required to control the conversion, including a programmable offline power-supply controller based on an Arm Cortex-M0+ core, a high-voltage startup circuit, a synchronous-rectification controller, and USB Power Delivery (USB-PD) circuitry in one package. USB-PD communication is implemented on the secondary side using on-chip reinforced galvanic isolation.

ST-ONE comes with 64 kB of embedded flash containing pre-loaded firmware that handles both the power-conversion functions and the communication protocols for USB-PD 3.1—including an optional programmable power supply (PPS) and electronically marked cable management.

The factory settings support plug-and-play designs based on ST's MasterGaN, a highly integrated power stage featuring advanced wide-bandgap transistors and optimized drivers that enable adapters to operate at higher switching frequencies than silicon-based designs. Should your project require a different output stage, ST-ONE's firmware can be easily reprogrammed to work with other GaN-based devices.

Double Benefits

With the ST-ONE chip, manufacturers can take advantage of economic and environmental benefits. Its high level of integration simplifies circuit design by significantly reducing the number of components, enabling this type of power supply to become more robust, affordable, and more widely adopted throughout the market. In addition to delivering high energy efficiency, it enables compact designs with a minimal amount of external components.

When combined with the smaller L/C elements made possible by the MasterGaN output stage's higher operating frequencies, ST-ONE opens the door to cost-effective designs with high power densities that also reduce recycling and overall environmental costs.*

ST-ONE, in production and available now in a SSOP36 package, is priced at $3.70 for orders of 1,000 pieces. For more information, visit www.st.com/st-one

*“If every power adapter achieved at least 1% higher efficiency, which is possible using the ST-ONE energy-recovery circuit design, the world could save about 93 terawatt-hours of energy, equivalent to the output of 15 nuclear plants,” commented Domenico Arrigo, Industrial and Power Conversion Division General Manager, STMicroelectronics. “In addition, if one billion chargers worldwide were to use our technology, 0.2 million tons of plastics and raw materials could be saved.”

Integrated 3-Phase BLDC Motor Controller and Gate Driver Shrinks BOM Costs

Infineon introduced a single-package gate-driver/microcontroller targeted at designs of three-phase brushless DC (BLDC) motors for battery-powered products. Housed in a (9 × 9 mm2) VQFN package, the controller family offers fully programmable motor-control solutions that allow engineers to reduce part count and overall size of cordless products such as cordless power tools, gardening products, drones, e-bikes, and automated guided vehicles.

The MOTIX IMD70xA controller family integrates all of the MOTIX 6EDL7141 3-phase gate-driver IC’s features and adds a XMC1404 microcontroller (MCU) that’s equipped with peripherals and specifications optimized for motor control and drives. It also inherits most of the high-end peripherals found in the XMC4000 family, including PWM timers, position interface (POSIF), and serial communication modules (including CAN).

The XMC1404 MCU also includes a 96-MHz math coprocessor to support demanding real-time algorithms, such as the calculations used in sensorless field-oriented-control (FOC) systems. In addition to supporting precise FOC operation, these features enable the motor-control ICs to adjust the gate-drive slew rate to minimize system EMI.

The controllers' on-chip, programmable high- and low-side charge pumps can support many other adjustable gate-driver parameters, including adjustable gate-drive supply voltage even at low battery voltage levels. In addition, both products come with a full suite of motor-drive-specific system protection features such as OCP, UVLO, overtemperature, and locked rotor detection, offering increased reliability and robustness.

The new devices have integrated precision power-supply and current-sense amplifiers, further reducing the need for peripheral circuitry. As a result, they lower external component count, simplify routing, and reduce BOM and assembly costs.

Availability

The MOTIX IMD700A and IMD701A ICs come in a 64-pin VQFN package with exposed bottom-side thermal pads and can be ordered now. Additional details (including links to datasheet and pricing information) can be found at www.infineon.com/imd700a and www.infineon.com/imd701a.

HW/SW Solution for 3-Phase BLDC Inverters Delivers 98%+ Efficiency, Saves PCB Space

Power Integrations added three-phase FOC capabilities to its Motor-Expert 2.0 library of easy-to-use motor-control configurations and diagnostics tools for the BridgeSwitch IC family. These modules add to the existing library of code and tools for single-phase motor applications.

Included is a reference design (DER-964) that can deliver up to 300 W of output power without requiring a heatsink. It removes the shunts and op amps seen in conventional feedback measurement and is suitable for a wide range of applications, such as compressors, range hoods, and residential and commercial fans and pumps.

The reference design is based on PI's BridgeSwitch integrated half-bridge motor-driver IC, which includes a motor-current output signal that maps the current passing through the low-side FREDFET. An internal sense-FET provides lossless current sensing. It can be used with any Cortex-M0 or equivalent microcontroller to create applications that deliver up to 98.2% efficiency.

In addition, the highly integrated design requires only three components to implement current feedback circuitry (versus 30 components in typical discrete solutions). Thanks to minimized component count and other on-chip features, the reference design needs only 65 × 50 mm of board space, a reduction of more than 70% in many cases.

Power Integrations’ three-phase FOC code is MISRA C-compliant and available on any Arm Cortex-M0 at 48 MHz; a hardware accelerator block isn’t required. It works directly with the Motor-Expert's GUI and terminal emulator; thus, designers can make real-time adjustments to motor speed and torque, as well as other input parameters. In addition, a motion scope feature displays linear graphs of important controller variables that can be viewed in real time.

Availability & Resources

The complete BridgeSwitch Motor-Expert 2.0 and three-phase motor-control software solution is available today and includes a downloadable manual for the software architecture, APIs, functions, calls, and variables used in the code. Pricing for the BridgeSwitch ICs starts at $1.69 in 10,000-unit quantities.

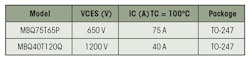

650-V IGBT is Optimized for Solar Inverters

Magnachip Semiconductor recently unveiled a new 650-V insulated-gate bipolar transistor (IGBT) for solar inverters. The new device's current density has been improved by 30% over the company's previous generation device, and it provides a minimum short-circuit withstand time of 5 µs. Its positive temperature coefficient makes it ideal for high-power designs that require parallel switching.

The 650-V IGBT also features anti-parallel diodes for fast switching and low switching loss, while guaranteeing a maximum operating junction temperature of 175°C. Based on standards issued by the Joint Electron Device Engineering Council (JEDEC), this new IGBT can be used for applications requiring strict power levels and high efficiency, such as solar boost inverters and converters, uninterruptible power supplies, and universal power inverters.

Magnachip's IGBT products for the solar-energy market:

For more information, visit www.magnachip.com.

Power Tools News

G2 Spice Models Boost Accuracy of Transient Modeling for Power Apps

A set of highly accurate G2 Spice models introduced by Toshiba Electronics will allow designers to better simulate the performance of their designs before committing to hardware. Alongside Toshiba’s existing G0 Spice models that emphasize computational speed over accuracy, the new range of G2 SPICE models simulates transient characteristics more accurately. Together, they can greatly reduce overall development time, cost, and risk.

These new G2 Spice models for discrete power devices are created using the macro model format. It combines multiple compact models to match the structure of the device, representing the electrical characteristics with a few nonlinear elements and a continuous arbitrary function.

Thanks to improved reproducibility of the high-current-domain characteristics of the ID-VDS curve, including the voltage-dependent characteristics of the parasitic capacitance, the new tools make simulations of switching events more accurate and closer to real-world measurements.

Available from Toshiba’s website, the G2 models cover low-voltage MOSFETs (12 to 300 V) and medium- to high-voltage MOSFETs (400 to 900 V). Versions are available for PSpice and LTSpice. For more company information, visit TEE’s site at www.toshiba.semicon-storage.com.

Interactive Component Search Tool Simplifies Locating the "Perfect Parts" for Your Design

With the new interactive component search tool from Kyocera AVX, users can more quickly and easily explore an extensive selection of the company’s proven portfolio of antennas, capacitors, circuit-protection devices, filters, couplers, and inductors. They also can view and purchase available stock from its authorized distributor network.

Accessible via computer, tablet, or smartphone, the portal's user-friendly interface features filtering menus that allow customers to quickly narrow down the list of suitable components and clickable product selections represented by component pictures.

Once users narrow their search to a specific product line, they will receive a list of active part numbers. Clicking one of the part numbers will reveal detailed product data including parameters; descriptive information; downloads such as spec sheets, datasheets, and product catalogs; and available product stock at authorized Kyocera AVX distributors.

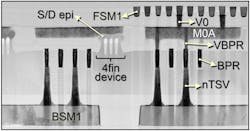

Brace Yourselves! Backside Power-Delivery Architecture May Usher in Power-Hungrier ICs

Could a new power-distribution architecture for ICs create new challenges for designers of power supplies for servers, EVs, and other high-power applications? It's very likely if a new technology recently demonstrated by imec, a Belgium-based electronics research consortium, reaches the market: The company presented a paper on the first experimental demonstration of a routing scheme for logic ICs with backside power delivery at the 2022 IEEE VLSI Symposium on Technology and Circuits.

The concept of backside power delivery allows designers to decouple the power-delivery network from the signaling metallization scheme in logic ICs, alleviating routing congestion in the back-end-of-line (BEOL) while delivering a power performance benefit. imec has been exploring several different implementations since 2019, but this one appears to be the first one to reach the demonstration phase.

At the system level, backside power delivery promises to improve the overall power-delivery performance, which increasingly suffers from a rise in power density and aggressive supply-voltage (or IR) drop.

The new power architecture is based on nano-through-silicon-vias (nTSVs) landing on buried power rails (BPRs). The BPRs connect to scaled FinFET devices, whose performance wasn’t impacted by backside wafer processing. The novel routing scheme with decoupled power and signal wiring acts as a scaling booster for future logic technologies (2 nm and beyond). It also offers a system performance benefit by improving the power delivery. In addition, imec demonstrated a performance boost by implementing a 2.5D MIMCAP in the backside.

More information about imec's backside power delivery technology is available here: Imec demonstrates backside power delivery with buried power rails for back- and frontside routing (imec-int.com)

Can Dual-Chemistry Battery Packs Cure EV Range Anxiety?

Our Next Energy (ONE), a Michigan-based energy-storage company, has signed an agreement with BMW Group to create a testbed for the company's Gemini Dual-Chemistry battery technology based upon the automaker's iX all-electric Sports Activity Vehicle. The Gemini dual-chemistry architecture, designed to give EVs an optimized mix of power density and performance, is expected to give the iX a range in the neighborhood of 600 miles.

In its announcement, ONE said that "the battery system has an energy density of 416 Wh/L (compared to approximately 245 Wh/L of the original pack) and uses a nickel-cobalt-manganese cathode and a graphite anode. The pack added an additional 331 kg in total to the original mass of the battery (and vehicle) while also adding 99.8 kWh of energy. The specific energy density of the pack we tested measured at 231 Wh/kg."

While ONE was light on any substantive details, it’s expected that the BMW testbed will use the same technology demonstrated earlier this year that enabled a Tesla Model S to travel 752 miles (at 55 mph).

The company also said that it plans to change the chemistry of its Gemini battery:

“Gemini will employ a new graphite-free anode and a nickel-cobalt-free cathode, improving energy density to approximately 450 Wh/L and 290 Wh/kg in the long term. We have 10-Ah cells on test that support the system targets above and plan to scale up these test cells to produce 1000s by mid-2022. We will integrate a full pack using Gemini architecture for pairing a LFP traction battery with a manganese-rich anode-free range extender by the end of 2022.”

With the stakes so high, the market is attracting its share of companies getting into EV batteries that are either based on badly conceived or even fraudulent technologies. That's why I'm very suspicious of any company claiming to have a "breakthrough technology”—including ONE.

But while ONE still must prove its technology is commercially feasible, the earlier Tesla demo, and a recent interview with ONE's CTO conducted by noted automotive manufacturing expert Sandy Munroe, indicate that this company has a good chance of being one of the handful of players that will still be standing in five years.