The Golden Rule of Board Layout for SMPS

Members can download this article in PDF format.

What you'll learn:

- Achieving an optimized board layout by successfully implementing the golden rule regarding traces.

- Looking at typical buck and boost regulator circuits.

This article explains the basis for achieving an optimized board layout, a critical aspect in the design of switch-mode power supplies (SMPS). A good layout ensures stable functioning of the switching regulator and minimizes radiated interference as well as conducted interference (EMI)—widely known by electronics developers. However, what’s not generally known is how an optimized board layout for a switch-mode power supply should look.

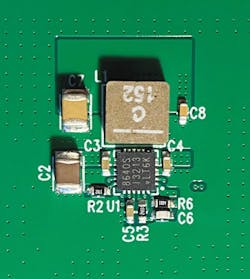

Figure 1 shows the circuit of an LT8640S evaluation board. It’s a step-down (buck) switching regulator that can tolerate input voltages of up to 42 V and is designed for output currents up to 6 A. All components have been placed very compactly.

Placing the components as closely together as possible on the board is a general recommendation. Though this statement isn’t false, it’s also not particularly suitable if the goal is to obtain an optimized board layout. In Figure 1, quite a few (11) passive components surround the switching regulator IC.

Which of these passive components have priority over the others in the placement and why?

In a switching-regulator PCB design, the most important rule is to route the traces that carry high switched currents to be as short as possible. Successfully implementing this rule will properly address a large part of the board layout for a switching regulator.

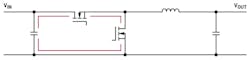

What’s the easiest way to implement this golden rule in the board layout? The first step is to find out which paths in a switching-regulator topology are critical. In these paths, the current flow changes with the switch transitions.

Figure 2 shows a typical circuit for a step-down converter (buck topology). The critical paths are shown in red. They are connecting lines in which either the full current or no current flows, depending on the states of the power switches. These paths should be as short as possible. For a buck converter, the input capacitor should be situated as close as possible to the VIN pin and GND pin of the switching regulator IC.

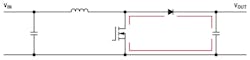

Figure 3 illustrates a basic schematic diagram of a circuit with a boost topology. Here, a low voltage is converted to a higher voltage. Once again, the current paths in which the current flow changes with switching of the power switches (shown in red).

Interestingly, the placement of the input capacitor isn’t critical at all; rather, it’s the placement of the output capacitor. It must be as close as possible to the flyback diode (or the high-side switch) as well as to the ground connection of the low-side switch.

After that, any other switching-regulator topology can be examined to yield information on how the current flow changes when the power switches are switched. The classic method involves printing out the circuit and drawing the current flow, using three differently colored pens.

One color is used to indicate the current flow during the on-time—that is, when the power switch is conducting current. The second color shows the current flow during the off-time—that is, when the power switch is switched off. And finally, the third color is used for all paths marked either only in the first color or only in the second color. The critical path, in which the current flow changes with the switching of the power switches, can then be clearly identified.

Inexperienced circuit designers often consider the board layout for a switching regulator to be black magic. The most important rule is to design the traces, in which the current flow changes with the switch transitions, to be as short and compact as possible. This can be explained easily, follows logical relationships, and is the basis for an optimized board layout in a switch-mode power-supply design.