Current Sensing: Past, Present, and Future

Members can download this article in PDF format.

What you'll learn:

- Common methods used to measure current.

- A new approach to current sensing: GaNSense technology.

For any electrical control system, input signals of both voltage and current are critical for the system to operate according to the intended design and in a safe manner. In power supplies and motor drives, for example, current is measured for control (like peak-current mode or average-current mode control in power converters), protection (like short-circuit overcurrent protection), and data-logging purposes.

Shunt Resistors

One of the simplest methods for measuring current is to add a shunt series resistor into the current path of interest, and then measure the voltage across it as a representation of that current—knowing the relationship of voltage = current × resistance, (V = I × R), and assuming a stable, or linear, resistance.

This popular method is simple and accurate. It can be used for dc or ac current measurements and is flexible for a variety of applications. While not intrinsically isolated, some vendors offer isolated amplifiers or isolated ADCs for this approach. Vendors like Allegro, Broadcom, ON Semi, Skyworks, Texas Instruments, and many others offer solutions in this area.

However, this current-sense method does introduce an additional power-loss element, especially at high current, which can be a severe limiting factor in high-power, high-efficiency systems. It also adds parasitic source inductance in the power path and gate loop of low-side switches, where it’s most unwanted, causing delayed turn-off and voltage spikes.

These resistors aren’t standard off-the-shelf components either. To carry the full rated load current, and meet typical accuracy of 1% resistance over temperature, very low on-resistance (RDS(ON)) FETs and highly optimized shunt resistors must be used. To avoid heavy losses, a variety of low- RDS(ON) FETs with large thermal package options are available from current-sense resistor providers such as Bourns, Ohmite, Susumu, Vishay, and others.

Pushing for low power loss and low voltage drop across these resistors then requires excellent op amps to gain and condition the signal properly for use. Further, to meet efficiency and thermal requirements with this added series resistance, designers also must use lower RDS(ON) and more expensive components to reduce the other power loss in the power path to compensate (for example, using even lower RDS(ON) power MOSFETs).

What started out as a simple measurement now requires multiple additional components that need to be carefully selected, designed, and powered properly, while also consuming PCB space and cost.

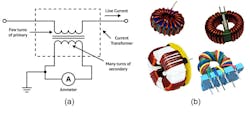

Current Transformers

Another common method of current measurement that simplifies the system when isolation is needed, or with high-power, high-efficiency systems, is using a current transformer (CT). Gain can be accomplished with the transformer turns ratio, isolation is built-in, and bidirectional current can be measured. In addition, no bias supply is required for the CT, regardless of whether it’s used in high-side (floating reference) or low-side (ground-referenced) configuration.

The downsides, though, are that dc current can’t be measured; duty-cycle limitations may prevent transformer saturation; and these CTs also are usually large components—most typically toroids like those in Figure 1, which may limit their adoption in high-density systems. LEM, Renco, Wurth, and many other magnetics vendors offer dedicated products focused on this approach.

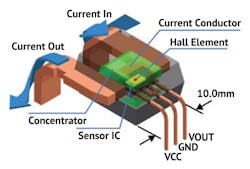

Hall-Effect Sensors

For applications at still higher power, or when dc current information is required, designers often look at sensing methods that minimize the lossy pass elements being added to the system (like shunt resistors or CT primary windings), and instead rely on measuring field effects of the system.

Considered “non-contact,” “lossless” sensors, methods like Hall-effect current sensors (Fig. 2) operate under the principle that for a given conductor (like a copper trace on a PCB) with current flowing through it, a proportional magnetic field is created around the current-carrying conductor. By measuring such a magnetic field, information on the value of the current that produced it can be obtained. The sensing element often has the PCB copper flow through the sensing-element package, and some others place the sensor above the copper trace and sense through proximity only.

Hundreds and thousands of amps can be measured with low loss because resistance and inductance isn’t being added to the system. However, the method becomes inaccurate at low current, can be made inaccurate by external fields or mechanical orientation, and often requires a zero-current offset and a concentrator to magnify the signal for a narrow range of current of interest. Furthermore, a dedicated bias power supply is required for such a measurement IC. Allegro, Koshin, Melexis, and many other vendors offer products focused on this approach.

Anisotropic Magnetoresistive (AMR) Sensing

The AMR IC is capable of sensing both ac and dc signals and offering a high-bandwidth solution up to 1.5 MHz, with an isolated output. It operates by having the current flow into the device through a low resistance “U-bend” in the leadframe, where it generates either a forward or reverse magnetic field that’s sensed by two differential current sensors.

This approach is attractive in that it’s fairly compact, resistant to external fields and noise, and has low offset error while also responding very quickly (<300 ns). Thus, it can be used in high-frequency control applications such as power supplies and motor drives using wide-bandgap semiconductors such as gallium nitride (GaN) and silicon carbide (SiC).

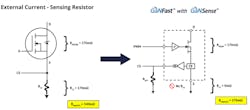

The Future: Introducing “GaNSense” Technology

With the continued push for higher efficiency, GaN-based power converters have become more popular in the market. In addition, with high levels of integration used in monolithic GaN power ICs, power converters could be pushed to higher frequency with a minimal number of external components, allowing for much smaller systems.

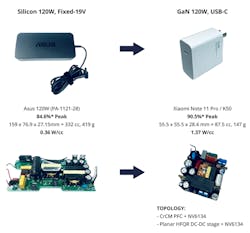

Ground-breaking products such as the latest fast mobile-phone chargers have been able to achieve power densities even 3X higher than best-in-class previous solutions. But the efforts to extract all of the capability out of GaN continued, and in late 2021, GaNSense technology offering further integration and expanded features was released.

In its simplest form, GaNSense is lossless current-sensing in-circuit, removing the shunt current-sense resistor and its associated headaches (Fig. 3). It improves the overall efficiency of the system with lower total series resistance, while also increasing robustness with fast, internal, 30- to 100-ns short-circuit protection.

This approach is “localized” in that it’s sensed and acted on locally to the current and power elements of interest. Localized control and response time allows this method to be fast and effective, while also minimizing corruption of the control signals from system noise, long traces, etc., compared to other methods. Therefore, it becomes possible to use this method not only for overcurrent failsafe and short-circuit protection, but also cycle-by-cycle current limit and current-mode control and regulation.

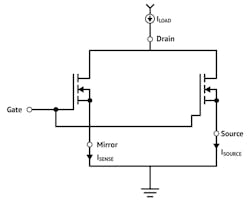

Such a self-governing power block may indeed represent the future of power-stage sensing and protection, enabling higher reliability, pushing the limits of performance, and freeing the main system controller to focus on more complicated control algorithms and responsibilities. This “lossless” current sensing in the current-sense (CS) block is implemented through a popular parallel current-mirror design technique, and further optimized to be used with high-speed GaN FETs.

As seen in Figure 4, within the CS block, the main power FET device is connected to the common drain and gate connections. For simplicity’s sake, we will show the source’s connected commonly as well. By using well-matched devices and a high on-resistance sense-FET (maybe >1000-1500X higher RDS(ON) than the main power FET), a small portion of the load current branches off to the sense FET and can be measured accurately through a variety of techniques. RDS(ON) and temperate affects are cancelled out naturally, too.

Because of the tight matching, the current is based on the ratio of the resistances of the devices only. As the sense FET has much higher RDS(ON) than the main power FET, the loss from this approach is negligible, especially compared to alternatives like shunt current-sense resistors in the main power path. The current limit is still adjustable and programmable, with the Current Sense (CS) pin and programming resistor.

All of these benefits translate to system improvements. For example, as seen in Figure 5, designers leveraged GaNSense technology to achieve an ac/dc 120-W mobile-phone charger that was 70% smaller, 65% lighter, and almost 6% more efficient than the previous production solution.

Summary

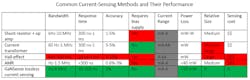

In motor drives and power supplies, voltage and current will continue to be signals that need to be monitored and measured for accurate and reliable real-time control, protection, and data logging. With a variety of applications and requirements comes multiple current-sensing approaches to meet the design goals in the most cost-effective and size-efficient manner.

A technology and approach has been discussed here with the advent of a near-ideal, lossless “GaNSense” current sensing fully integrated with the power device that’s fast, accurate, and can serve the critical functions of both control and protection with effectively zero size and cost impact. While not an exhaustive study, some of the most common methods used in industry today have been discussed and are summarized in the table above.