An energy-harvesting embedded controller developed by Renesas Electronics can eliminate the need to use, or replace, batteries in IoT devices. Based on the company’s silicon-on-thin-buried-oxide (SOTB) process technology, the new embedded controller achieves extreme reduction in active as well as standby current consumption, a combination that wasn’t previously possible to achieve in conventional microcontrollers (MCUs). Thanks to the SOTB-based embedded controller’s extreme low-current levels, system manufacturers can go one step further and completely eliminate the need for batteries in some of their products by harvesting ambient energy sources such as light, vibration, and flow.

Use of extreme low-power and energy harvesting gives rise to a new market of maintenance-free connected IoT sensing devices with endpoint intelligence for applications in industrial, business, residential, agricultural, healthcare, and public infrastructure, as well as health and fitness apparel, shoes, wearables, smartwatches, and drones. Renesas has already begun supplying the new embedded controller to beta customers.

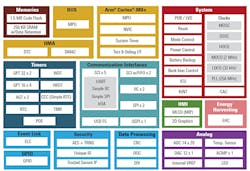

The company’s first commercial product using SOTB technology is the R7F0E embedded controller, a 32-bit, Arm Cortex-based embedded controller that operates up to 64 MHz for rapid local processing of sensor data and execution of complex analysis and control functions. Consuming just 20-μA/MHz active current and 150-nA deep standby current, approximately one-tenth that of conventional low-power MCUs, these characteristics suit the R7F0E for extreme low-power and energy-harvesting applications. Figure 1 shows a block diagram of the R7F0E.

1. Block diagram of the R7F0E.

The R7F0E overcomes many challenges faced by system designers who want to build cost-effective products with efficient energy-harvesting capabilities. A unique and configurable Energy Harvest Controller (EHC) function increases robustness and minimizes costly external components. The EHC enables direct connection to many different types of ambient energy sources, such as solar, vibration, or piezoelectric, while protecting against harmful inrush current at startup. The EHC also manages the charging of external power storage devices such as supercapacitors or optional rechargeable batteries.

R7F0E Features

Energy Harvest Controller (EHC)

- Charge management of local energy storage devices

- Startup current management – only 5 μA required from harvested energy source

CPU: Arm Cortex-M0+

- Operating voltage: 1.62 to 3.6 V

- Operating frequency: Up to 32 MHz, up to 64 MHz in boost mode

- Memory: 1.5-MB flash, 256-kB SRAM, up to 256-kB SRAM data retention consuming only 1 nA per each kilobyte

Current consumption at 3.0 V: Active: 20 μA/MHz

- Deep standby: 150 nA with real-time clock source and reset manager active

- Software standby: 400 nA while retaining core logic and 32-kB SRAM data. Real-time clock source and reset manager active

Internal Peripherals

- Analog-to-digital converter (ADC): 14-bit, 33-ksample/s operation frequency, 3-μA consumption

- Graphics: 2D graphics data conversion and Memory-In-Pixel display interface

- Security and Encryption: True random number generator, unique ID for each R7F0E device, AES encryption acceleration

- Packages: 100LQFP/144LQFP/156WLBGA

SOTB Technology

The SOTB process technology realizes extreme reduction of both active and standby current, which has typically been a tradeoff and not possible to achieve in conventional MCU process technologies. With SOTB, the silicon substrate, an oxide film (buried oxide, or BOX) is buried under a thin silicon layer on the wafer substrate. No impurities are doped to the thin silicon layer, which makes it possible to maintain stable operation at low voltages. The devices can therefore deliver high computing performance with excellent power efficiency. At the same time, the potential of the silicon substrate below the BOX layer is controlled with a back-bias circuit to reduce leakage currents to further suppress standby power consumption.

Among the key features of the SOTB technology is that it enables battery-free applications for industry, home, infrastructure, health devices, and more. It uses one-tenth the active and standby current of conventional low-power MCUs. Furthermore, SOTB manages harvested energy sources.

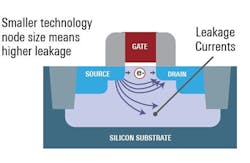

2. Illustrated is a conventional bulk transistor.

Figure 2 shows a cross-section of conventional bulk transistor and Figure 3 shows the SOTB transistor.

3. Cross-section of the SOTB transistor showing its bias control and buried-oxide insulation layer.

About the Author

Sam Davis

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.

You can also check out his Power Electronics blog.