Hydrogen Invigorates Li-Ion Battery Capacity, Durability, and Charge Speed

In recent years, graphene has been the subject of intense research in the field of high-density energy-storage systems. This is in large part because of its high thermal conductivity and electron mobility. However, the widespread use of this unique material in lithium-ion (Li-ion) batteries hinges on the ability to produce it in large quantities and at low cost.

Now, scientists from the Lawrence Livermore National Laboratory (LLNL), a national security research center in California, have discovered that treating graphene electrodes with hydrogen can actually increase the capacity and transport speed of Li-ion batteries. The research is significant because these performance gains can help lower the cost of manufacturing these batteries.

The findings, which were published in the journal Nature Scientific Reports, focused primarily on strengthening the bonds between the lithium ions moving throughout the battery and the graphene electrodes. The capacity, voltage, and energy density of the battery are determined by the binding between the lithium ions and the electrode material. However, subtle changes in the structure, chemistry, and shape of the electrodes can significantly affect how tightly the lithium ions bond to the material.

Graphene, a sheet of carbon atoms bound together in a honeycomb lattice pattern, suffers from defects in the manufacturing process. The material is produced through chemical synthesis and most methods leave behind significant amounts of atomic hydrogen. However, the effect of these hydrogen deposits on the material’s electrochemical performance has been difficult to pin down.

In a series of experiments, the scientists proved that the low-temperature treatment of defected graphene with hydrogen can actually improve the material’s electrochemical performance. The hydrogen interacts with the defects in the graphene and opens small gaps to facilitate easier lithium penetration. In addition, the hydrogen allows lithium ions to bond more easily near the electrode edge, increasingly the battery’s overall capacity.

The experiments, which were funded by the Laboratory Directed Research and Development program, could represent a significant step forward for graphene, which has languished in recent years under limited production and high manufacturing costs. It has already been proven that conventional electrode materials can be enhanced with graphene-based materials. But the LLNL research suggests that a controlled hydrogen treatment may be used to optimize lithium transport in graphene-based anode materials.

According to Brandon Wood, an LLNL scientist and a co-author of the research paper, the hydrogen treatment “results in some small changes to the graphene chemistry and morphology that turn out to have a surprisingly huge effect on performance.” The hydrogen treatment accounts for the graphene defects, allowing Li-ion batteries to have a longer lifespan, faster charging times, and greater capacity.

These qualities have long been elusive in the production of high-density Li-ion battery packs. In the case of electric vehicles and plug-in hybrids, battery prices will have to fall up to 80% before they can be competitive with gas-powered cars, according to research from the U.S. Department of Energy. The battery packs for the Chevrolet Volt and Nissan Leaf, for instance, cost about $8,000 and $12,000 respectively—a significant part of the manufacturing costs.

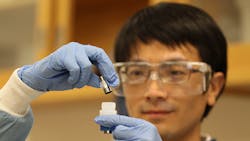

There are many potential uses for graphene materials in the field of high-density energy storage, according to Jianchao Ye, a staff scientist at the LLNL’s Materials Science Division, and the leading author of the paper. The research team used 3-D graphene nanofoam in their experiments not only because it is composed chiefly of defective graphene, but because of its wide range of applications. These include hydrogen storage, catalysis, filtration, insulation, energy sorbents, capacitive desalination, supercapacitors, and Li-ion batteries.

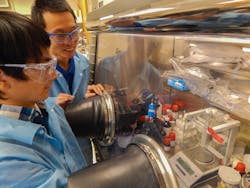

The team’s experiments involved combining heat-treatment conditions and hydrogen exposure to the graphene electrodes. The scientists monitored the electrochemical performance of the graphene nanofoam, and from these results, they “were able to trace the improvements to subtle interactions between defects and the dissociated hydrogen,” Wood says.

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.