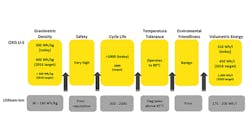

While advances in battery technology are critical for next-gen products across multiple markets, the requirements of military applications take on a different meaning in terms of safety. A new lithium-sulfur-based battery, which offers energy density greater than 300 Wh/kg, has an enhanced safety chemistry that can prevent fire yet retain functionality, even after accidents. Developed by OXIS Energy, the technology has a long lifecycle of 2000 cycles before capacity reduces to 80% of its beginning of life (BoL).

OXIS’ lithium-sulfur batteries have a potential performance five times greater than Li-ion batteries. The cells also have a 100% available depth-of-discharge, superseding previous 80% discharge ranges that left the door open to damage caused by over-discharge. The batteries’ two main features—a ceramic lithium sulfide passivation layer and a non-flammable electrolyte—help it withstand extreme abuse scenarios, another key factor for military applications.

The extremely lightweight battery suits it for soldiers and electric vehicles (OXIS is already in the planning stages to reduce its weight by a further 50%). It could also be used for automotive, solar energy storage, marine transportation, and advanced nanotechnology-enabled applications. OXIS recently received a Frost & Sullivan Award for Technology Innovation for the lithium-sulfur battery.