Modern Design Tools Measure The Invisible And Make Circuits Safer

Though we see its effects on other things, we cannot see electricity itself. So how can we measure its voltage? Oh, but we can, with modern and even old-fashioned tools. In fact, measuring something is really making a comparison. We take a known (a standard or a reference) quantity and compare it to the unknown quantity.

Related Articles

- Calibration: Needless Or A Necessity?

- Design For Power Efficiency Like A Symphony Conductor

- Turn Off Vampire Power To Save Your Money And Electronics

Mechanical Measurement Of The Visible Over Millennia

Though electricity is invisible, we can see its effects and measure them. Someone without a science background may say, for example, “What about lightning?” We do not see electricity, but we definitely see the super-heated air (plasma) glowing brightly. Also, children often place 9-V batteries on each other’s tongue as a joke. We feel the insult to our nervous system, but we cannot see anything. Doctors can probe the brain with small electrical currents, and the patient’s nervous system might “see” light flashes. In each of these examples, we can measure that invisible voltage if we have the right, highly accurate tool.

This file type includes high resolution graphics and schematics when applicable.

Measuring physical objects is easy, and it has been done for centuries. Take a measuring stick (i.e., the known quantity) and measure a box. You find that the box is three sticks wide by four sticks deep and five sticks high. Great. But how do we help someone elsewhere construct the same size box? We identify our stick as “a standard stick” and carefully make more just like it. That was the process essentially practiced by different villages and authorities since the Sumerian civilization over 6000 years ago. It is also why we have so many different measurement tools today (Fig. 1).

The value of accurate measurements has long been understood. In fact, measurements were so important that they were mandated in Biblical laws2 and they were the purview of the gods in Egypt, Greece, and Rome. Alexander could not have conquered so many countries without precisely measured military equipment. Rome could not have built its impressive system of aqueducts and far-reaching roads without precise measurement techniques. Then in 1889 the world standardized on platinum-iridium meter rods kept in a temperature-controlled vault in France. Today, our modern linear measurement unit is tied to the wavelength of a certain light. This is a major advance because it is reproducible in laboratories worldwide.3

Measuring The Invisible Over The Last 100 Years

To this point we have been reviewing the measurement of matter, substantive things like boxes, siege equipment, acreage, road dimensions, and buildings. How do we measure something invisible like electricity, specifically electromotive force or voltage? The answer is really not so different. We still compare a known (standard or reference) voltage with the unknown voltage. Simple enough, but what do we use for a reference?

Early attempts to measure voltage used specialized batteries that relied on repeatable chemistry. As with linear measurements, the reference had to be dependable, repeatable, stable with time and temperature, and, hopefully, fairly rugged. Regrettably, many of the early batteries produced varying results.

From 1905 to 1972, the Weston cell was the world’s voltage standard (Fig. 2).4 To use it, one had to compare two voltage sources or the ratio between two voltages. This cell was very delicate and required extreme care, which made it a specialized laboratory tool and not a device for popular use. Standard cells like Weston’s changed voltage when it supplied current, and the cell needed to be held at a constant temperature. As most of us have experienced, errors propagate. An error in the primary standard is a potential safety issue, as the calibration of all the secondary standards will reflect any primary errors.

Before modern electronics it was very difficult to make really high-impedance measurements, so scientists did the best they could. In the early nineteenth century the galvanometer5 emerged as a magnetic compass similar to those used to navigate using the earth’s magnetic field. The compass was placed inside a loop of wire to detect the magnetic field when current flowed. Many turns of wire in the loop increased the sensitivity.

A galvanometer was first used as a null detector. When two equal voltages were applied, no current flowed and the compass needle did not deflect. A high-resistance wire could be placed across the higher of the two battery voltages, and a contact slid up and down the wire. The voltage of the slider was then compared to a standard (lower voltage) cell using the galvanometer null. The ratio of the mechanical position of the slider on the wire was also the ratio of the two voltages. Wow. We just discovered how the potentiometer was invented and named. It measures the ratio of the electrical potential.

Weston cells were superseded by superconducting Johnson junctions,6 which are laboratory primary standards. The standards that we use today in industry are secondary standards. In the 1970s it was not unusual for engineers to bring their own mercury battery and a reference zener diode to make measurements at trade shows. Migrating from booth to booth, engineers would measure using the best voltmeters by the industry’s leading manufacturers. Friendly rivalries and bets ensued over which voltage was correct. Many such discussions (and friendly arguments) could, and usually did, continue through dinner and last into the night over drinks.

Emerging Bandgap Technologies Enhance Device Safety

So much for some fun. Then several technologies changed all that investigative work and brought very accurate voltage references to the masses. And that very same voltage accuracy introduced a new level of safety into electronics.

For just a few dollars anyone can now have buried zeners and bandgaps from the minds of pioneering leaders like Robert Widlar and Paul Brokaw. Accurate, temperature-stable, and, most important, reliable voltage references are used in many IC applications today. This increases accuracy and, thus, safety because the voltage reference determines analog-to-digital converter (ADC) and digital-to-analog converter (DAC) accuracy.

Both zener and bandgap technology are firmly rooted in semiconductor physics. Bandgap technologies evolved because engineers wanted to leverage the tasks that ICs do well. Transistors built at the same time and positioned next to each other on the same substrate match in gains, leakage, and track with temperature. Two transistors with different current densities can be trimmed and subtracted to make a voltage that varies little with temperature.

This temperature stability translates to safer precision in the ADCs and DACs used in many applications. Details about bandgap references are found in a tutorial7 that links to a free calculator emulator. Using that calculator, one can simulate the bandgap and trim curvature correction to better understand the bandgap technology. Even the bandgap’s necessary startup circuit is explained.8

State-Of-The-Art Tools For Measuring The Invisible Today

For just a few dollars we can have a voltage reference with an initial accuracy of 0.02%, a temperature coefficient of 1 part per million per °C, and 1.5-μVp-p noise. Weston would be surprised and pleased to see the changes in the state of the art that happened in just over 100 years! Today’s voltage reference is a rugged industrial tool, where the Weston cell was a fragile laboratory device that needed constant professional attention.

Voltage references can be sorted into different categories. The first category is shunt or two-terminal devices like the MAX6138A versus series or three-terminal regulators. The three-terminal references like the MAX6341 can be trimmed by a few percent or are adjustable over larger ranges.9 A programmable reference like the DS4305 acts like a sample and hold that never droops. Other voltage-reference parameters need to be considered for each application: high accuracy, low noise, low drift, low power, small packages, low cost, automotive grade, and calibration.

So how do we use a voltage reference to measure voltage? We start with the old-fashioned way: use a potentiometer like the MAX5482 to divide the reference or the voltage and then compare them. What? We advanced the state of the art to measure voltage, but we are going back 100 years now to do it?

Yes, that specialized potentiometer, developed 100 years ago, is called a Kelvin-Varley divider. It can resolve voltages to 0.1 ppm or 1 in 10 million ppm, and it is surprisingly stable and repeatable in a laboratory. Specialized potentiometers are expensive, but clearly state of the art at greater than 23 bits of equivalent resolution. A Kelvin-Varley divider was the mechanical predecessor of our current 24-bit ADCs like the MAX11201.

Today, we have gain. But like all things in engineering, we always trade one thing for another. We now fight offsets, drifts, and temperature stability, which are not insurmountable problems. It just means that we must find clever new ways to look at the issues. It seems obvious, but we must also understand what we are measuring.

What about the innovative galvanometer? It too has advanced to become devices on torsion balances, deflecting light with a mirror in a vacuum to minimize mass and stiction. There are similar advances in electronics, vacuum electrostatic voltmeters, sigma-delta ADCs (such as the MAX11202), and chopping amplifiers (like the MAX4209). In each case, we must always select the best part for the application, acknowledging the limitations and tradeoffs of each.

A Practical Example Familiar To All

Proper system design and calibration will ensure accurate voltage measurement, and that is important for safety. Consider a doctor looking at your heart. The voltage recorded has far-reaching implications. It could mean life or death. In the operating room, doctors place a pressure sensor in an artery to monitor blood pressure instantly. There is no time to inflate a cuff and wait tens of seconds. The anesthesiologist needs information in real time (the ADC’s job) and precision control (the DAC’s task) of the gas and fluids administered to the patient. When measuring the invisible, suddenly device calibration, accuracy, and good design are very personal and important.

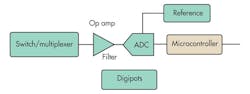

Let’s examine the functions that measure the invisible voltage and impact our safety in our example application. Figure 3 is a common application that senses a physical parameter such as temperature, pressure, flow, level, voltage, current, proximity, and light. In each of these measurements it is convenient to change the physical parameter to an analog electrical voltage and then convert it to a digital representation for a microprocessor to interpret.

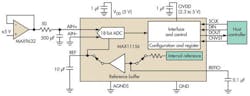

An external voltage reference like the MAX6341 is used when more accuracy and less temperature drift are needed for the ADC. The ADC in this application is a sigma-delta converter (Fig. 4) that is oversampled, which requires an RC filter (between the op amp and ADC). If the ADC is not oversampled, then a more complex filter would be necessary.

To the left of the Figure 3 circuit (not shown) would be protection for electrostatic discharge (ESD), radio frequency interference (RFI), and electromagnetic interference (EMI). A separate tutorial outlines the components for ESD, RFI, and EMI that are required for specific applications.10

Conclusion

Some sage people have said that nothing much changes over time. Well, maybe so. But it does depend on your subject. In just a few recent decades we have seen the emergence of voltage references, potentiometers, and other devices that accurately measure the invisible—voltage.

We all understand the importance of highly accurate measurements. But so often we forget how those same measurements impact the safety of the application. That is most definitely true in our example here, the heart patient. If we simply substitute our name for the word “patient,” it would certainly drive home the importance of safety when measuring invisible voltage. This is probably why there is no disputing the necessity for accurate design and calibration for safe voltage measurement.

Does this mean that we are at the end of the road in developing better measuring tools with better resolution and lower noise floors? No. Hardly the case. The human mind knows no limits and we can all proudly stand on the shoulders of technology giants who came before us and say, “With our present understanding of the laws of physics, let’s try this….”

References

1. The Greco-Egyptian god Serapis dates from the time of Ptolemy 1, who founded his new dynasty in Egypt after the death of Alexander the Great in 323 BCE. For more on the significance of Serapis, you can start at http://en.wikipedia.org/wiki/Serapis.

2. Leviticus 3:35, 36, “‘YOU must not commit injustice in judging, in measuring, in weighing or in measuring liquids. YOU should prove to have accurate scales, accurate weights, an accurate e′phah (a dry measure, 22 L [20 dry qt]), and an accurate hin (a liquid measure, about 3.67 L ([7.75 pt]).”

3. Beers, John S., Penzes, William B., The NIST Length Scale Interferometer, J. Res. Natl. Inst. Stand. Technol. 104, 225 (1999), http://nvlpubs.nist.gov/nistpubs/jres/104/3/html/j43bee.htm.

4. A voltaic cell from Edward Weston’s 1893 US Patent 494,827. For more information, go to http://www.google.com/patents/US494827.

5. Much has been written on the galvanometer. You can start a review at https://en.wikipedia.org/wiki/Galvanometer.

6. Planning Report 01-1, Economic Impact Assessment of the NIST's Josephson Volt Standard Program, Prepared by: David P. Leech TASC, Inc., for National Institute of Standards & Technology, Program Office Strategic Planning and Economic Analysis Group, July 2001, page 7, Figure 2, http://www.nist.gov/director/planning/upload/report01-1.pdf.

7. Maxim Integrated tutorial 5062, “Bandgap Reference Calculator Tutorial,” www.maximintegrated.com/AN5062.

8. Maxim Integrated tutorial 4606,“Self-Starting Can Be Hard to Do—Understanding Power-on-Reset Requirements in Regulators and Bandgaps,” www.maximintegrated.com/AN4606.

9. Maxim Integrated application note 4419, “Understanding Voltage-Reference Temperature Drift,” www.maximintegrated.com/AN4419.

10. See Figure 2 of Maxim Integrated tutorial 4645, “A Power Engineer: the Super Hero in a Design?” http://www.maximintegrated.com/AN4645. Additional reference material can be found at Maxim Integrated tutorial 4991, “Oops... Practical ESD Protection vs. Foolhardy Placebos,” http://www.maximintegrated.com/AN4991, and Maxim Integrated application note 4491, “Damage from a Lightning Bolt or a Spark—It Depends on How Tall You Are!” http://www,.maximintegrated.com/AN4491.

Bill Laumeister is an engineer in strategic applications at Maxim Integrated Products. He works with customers who use Maxim’s analog and digital integrated circuits. He has more than 30 years of experience and holds several patents.

About the Author

Bill Laumeister

Bill Laumeister is an engineer in strategic applications at Maxim Integrated Products. He works with customers who use Maxim’s analog and digital integrated circuits. He has more than 30 years of experience and holds several patents.