Even though they have around three times the energy density of lead acid and NiMH, lithium-ion batteries can be unstable. The batteries in electric vehicles have been known to catch fire following accidents. The Federal Aviation Administration has even considered a moratorium on shipping batteries for fear that they could ignite in a plane's cargo hold.

Over the last month, as the mainstream media have raised questions about their overall safety, and engineers have guaranteed that failures are extremely rare, two research projects have developed rechargable batteries with internal fail-safes to prevent the catastrophic failures that make them catch fire.

Li-ion batteries can short-circuit and overheat when severely damaged, overcharged, or contaminated by metallic dust. Too much heat triggers a chain reaction known as a thermal runaway, in which the flammable electrolyte inside the battery catches fire. Low-quality separators between the battery’s electrodes can also cause thermal runaways.

The most recent research to address these problems comes out of Stanford University. Researchers have developed a temperature sensor that can shut down the battery before it overheats, preventing a thermal runaway. In addition, the sensor is capable of restarting the battery automatically once it cools down.

Writing in the journal Nature Energy, the researchers said that they had based their design on wearable sensors for measuring body temperature. The sensor is made out of a thin film of elastic polyethelene, and embedded in the film are tiny nickel particles, or spikes, coated in graphene.

“We attached the polyethylene film to one of the battery electrodes so that an electric current could flow through it,” says Zheng Chen, lead author of the paper. “To conduct electricity, the spiky particles have to physically touch one another. But during thermal expansion, polyethylene stretches. That causes the particles to spread apart, making the film nonconductive so that electricity can no longer flow through the battery.”

The polyethylene film expands when the battery’s temperature is above 160°F, causing the spike to separate and the battery to shut down. When the temperature falls back under that threshold, the polyethylene contracts and the battery generates electricity again. The temperature threshold can be adjusted with different materials.

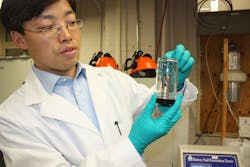

A similar study from Penn State uses sensors to shut down batteries at high temperatures. Researchers worked closely with large-format batteries—the kind used in electric vehicles and other gadgets—that require more power than smartphones and computers. The study was published in the journal Scientific Reports this month.

The team worked with a grant from the U.S. Department of Energy’s Computer Aided Engineering for Electric Drive Vehicle Batteries project, which targets batteries that can survive accidents as well as adapt to weather and temperature changes. Automakers and battery companies are working to increase battery density to extend the driving range of electric vehicles.

But at these higher densities, battery failures have the potential to cause more violent thermal runaways. Chao-Yang Wang, a professor of mechanical, chemical, and materials engineering at Penn State, notes “you are compressing more and more energy into a smaller space, and you have to careful when you do that."

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.