SEPIC-Fed Buck Converter’s Lowered Losses Elevate Efficiency

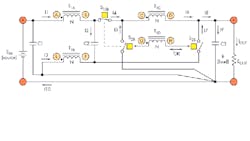

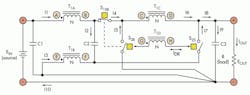

Two critical issues, efficiency and transient response, continue to tag-team the power-electronics arena. CUI takes them on with its patented SEPIC-fed buck (SFB) converter (Fig. 1). The SFB topology fundamentally improves power-conversion efficiency and transient response while retaining the simplicity and low cost of a synchronous buck converter.

Related Articles

- Optimize Your POL Buck-Converter Integration

- Fundamentals Of Buck Converter Efficiency

- Improved Power ICs Give Supply Designers More Bang For The Buck

The topology tackles both conductivity losses and switching losses. To overcome the I2OUTR losses in the buck converter, multiple energy delivery paths are made available to split the load current. It integrates a buck converter into a single-ended primary inductor converter (SEPIC) so it receives energy from the SEPIC inductors. The outputs of both deliver energy to the load in parallel.

This file type includes high resolution graphics and schematics when applicable.

When the controlling switch shared by both converters is ON, the buck portion delivers energy to the load while the SEPIC portion stores energy in the magnetic element and feeds the buck portion. When the controlling switch is OFF, both the buck and SEPIC portions deliver stored energy to the load.

An extremely fast, controlled turn-off commutation of the control switch, made possible by a gate-charge extraction (GCE) mechanism inherent in the topology, addresses the significant turn-off loss issue in the buck. Lower voltage and current stresses on the power switches also dramatically reduce their turn-on losses. On the transient response, reduced current level on the integrating inductors and increased reset voltage bring fundamentally faster response from the power stage.

The converter has a voltage-transfer ratio of EOUT/EIN = (2 – D), and it complementarily combines the characteristics of both the buck and SEPIC converters. This reduces voltage and current levels in the magnetic and switching devices, which in turn reduces conduction and switching losses. In addition, a new volt-second structure on the magnetic element boosts the power stage’s transient response.

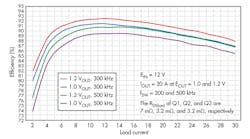

Testing results, using a prototype SFB converter at 300 and 500 kHz, revealed that despite the relatively high on resistance of the switches that were used and the additional power loss from the current transformer, the device still achieved efficiencies of 86.9% at 1 V (at 300 kHz) and 88.0% at 1.2 V (at 500 kHz) (Fig. 2).

If updated with newer devices that have an on resistance of 1.8 Ω, nearly 835 and 880 mW of conduction losses are saved at 1.0 and 1.2 V, respectively. Furthermore, if the control scheme is changed to voltage-mode control, combined power savings at the switches and transformer would increase efficiency to about 90.0% and 90.9% at 1.0 and 1.2 V, respectively.

Results also show that the efficiency difference between 300 and 500 kHz is minimal, indicating that frequency-dependent switching losses are relatively small in the SFB converter, smaller than in the buck converter.