Silicon Nanofibers Boost Electric-Vehicle Battery Performance

Conventionally produced lithium-battery anodes are made using copper foil coated with a mixture of graphite, a conductive additive, and a polymer binder. Graphite’s performance, however, has been nearly tapped out, so researchers have begun experimenting with other materials. Silicon has proven effective, but it often suffers from significant volume expansion that can degrade the battery.

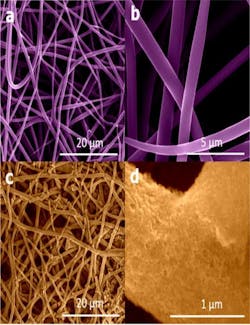

Enter a new paper-like material, developed by researchers at the University of California, Riverside’s Bourns College of Engineering, which has the potential to increase the amount of energy that can be delivered per unit weight. For use in the batteries of electric vehicles and personal electronics, the material consists of sponge-like silicon nanofibers that are 100 times thinner than human hair.

The nanofibers were produced through electrospinning, where 20,000 to 40,000 V are applied between a rotating drum and a nozzle, emitting a solution composed of tetraethyl orthosilicate, or TEOS (TEOS is a chemical compound frequently used for semiconductors). The nanofibers are then exposed to a magnesium vapor that produces the sponge-like silicon fiber structure.

The nanofiber structure created in the lab circumvents the battery-degradation issue inherent with traditional silicon—it allows the battery to be cycled hundreds of times without degrading significantly. The technology is also scalable. The team was able to produce several grams of silicon nanofibers at a time, even at the lab scale. Typical free-standing materials grown using chemical vapor deposition, such as carbon nanotube or silicon nanowires, have only previously been produced in very small microgram quantities.

According to the team, “Eliminating the need for metal current collectors and inactive polymer binders while switching to an energy dense material such as silicon will significantly boost the range capabilities of electric vehicles.” Looking toward the future, the team will implement the silicon nanofibers into a pouch-cell-format lithium-ion battery, a larger-scale battery format that can be used in electric vehicles and portable electronics.

The findings were published in the paper, “Towards Scalable Binderless Electrodes: Carbon Coated Silicon Nanofiber Paper via Mg Reduction of Electrospun SiO2 Nanofibers,” for the Nature Scientific Reports journal. It was written by Mihri Ozkan, professor of electrical and computer engineering, Cengiz Ozkan, professor of mechanical engineering, and six of their graduate students.

About the Author

Iliza Sokol

Associate Content Producer

Iliza joined the Penton Media group in 2013 after graduating from the Fashion Institute of Technology with a BS in Advertising and Marketing Communications. Prior to joining the staff, she worked at NYLON Magazine and a ghostwriting firm based in New York.