Download this article in PDF format.

Brushless dc (BLDC) motors offer multiple benefits over other types of dc motors. They’re efficient, reliable, run at high speeds, are compact for their power level, and produce little or no EMI. However, drive circuit complexity and cost have limited their adoption.

The good news is that recent developments in semiconductor drive circuits are making BLDC motors more desirable. In fact, these new drive circuits may influence you to make BLDC motors your first choice for new motor-based consumer appliances and industrial products.

Sponsored Resources:

- Meet Smart Gate Drive

- Architecture for Brushless-DC Gate Drive Systems

- Motor Drive Protection with TI's Smart Gate Drive

BLDC 101

Brushless dc motors, unlike more common dc motors, have a strong permanent magnet rotor and fixed stator windings. The windings are usually connected in a three-phase configuration requiring three different drive signals to three sets of windings. The driving signals are applied by a controller to create a rotating magnetic field that interacts with the poles on the rotor to produce a smooth continuous rotation.

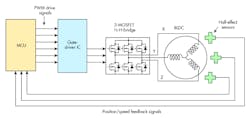

The controller gets its inputs from position sensors carefully located around the perimeter of the stator. These are often Hall-effect sensors that tell the controller when to turn the drive voltages off and on, creating the rotation. The stator windings are usually driven by MOSFET half-bridge circuits. IGBTs are used to drive larger motors with higher voltage-current needs.

Figure 1 shows a simplified arrangement. Note that a microcontroller produces the initial drive pulses that are conditioned by the gate drivers to operate the MOSFET switches connected to the windings X, Y, and Z.

1. Shown is the general configuration of a BLDC motor and its drive system.

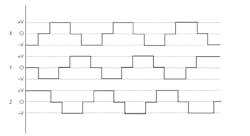

BLDC motors are sometimes called electronically commutated motors. While they’re designated as dc motors, the drive signals are a form of ac. The drive circuits are dc-to-ac inverters. Figure 2 shows the signals applied by the MOSFETs to the windings. These ac pulses are 120 degrees apart. At any instant, one pulse is positive, one pulse is negative, and the third is open (O) or floating. This sequence of pulses keeps the rotor turning smoothly.

General benefits of the BLDC include the fact that no mechanical commutator and brushes are used as in standard dc motors. Brushes wear out and shorten service life. In addition, the brush-commutator switch combination produces arcing that, in turn, causes electrical noise. The BLDC motor eliminates these problems. It’s more reliable, more efficient, and produces less EMI, plus it offers more torque and power for their size than other dc motor types.

2. The waveforms applied by the power MOSFETs to the motor windings are pulsed ac.

While the BLDC is generally superior to other dc motors, they have their issues. They’re more complex than other forms to dc motors. In addition, the MOSFET drivers require special gate-drive signals and protection from switching sequencing. Now, special gate-drive circuits are available to mitigate these problems.

Gate Drivers: The Key to Superior BLDC Motor Control

Different MOSFETs have widely differing gate-drive requirements. The gate-drive current must be exactly as needed for the chosen MOSFETs, meaning a special design. The alternative is a gate-driver IC that you can adjust to provide the desired level of drive current.

Another issue is that the MOSFETs generally need protection from several potential problems. One of these is shoot-through, a condition that occurs when the gate-drive timing isn’t right. It causes both drive MOSFETs to turn on at the same time, leading to a catastrophic short and failure. Some available drivers use a state machine to produce the drive signals that include a dead time between drive pulses, thereby eliminating the problem.

Another problem is dV/dt turn-on and the resulting MOSFET damage due to the transients. This is caused by parasitic capacitance. The problem can be mitigated by proper timing of the MOSFET switching.

Other faults are caused by external shorts, solder bridges, or MOSFETs hung up in one state or another. These can be dealt with by monitoring the gate-source drive voltage and providing feedback to correct the problem.

Texas Instruments’ Smart Gate Drive ICs are designed to deal with all of these needs. These drivers are easy to use and provide the desired protection. In addition, they integrate most components, potentially eliminating up to 24 external components generally required in discrete-component designs.

An available instructional video introduces TI's smart gate-drive technology and details its protection and ease of use features. Access it here.

The integrity and function of the power-stage MOSFETs are crucial in any motor system. The smart gate-drive technology provides protection against MOSFET failures, making your system more robust and efficient. This resource shows how.

Architecture for BLDC Gate-Drive Systems

Brushless dc motor drive systems can assume a number of different possible architectures, each with its own system implementation. An example is an alternative feedback approach that eliminates the Hall-effect sensors in favor of a sensor-less method.

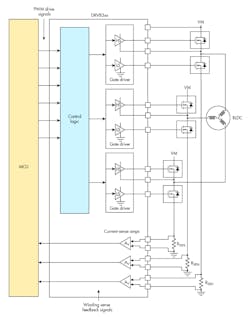

3. This simplified illustration of a field-oriented control (FOC) BLDC system shows the driver IC and the related circuits.

This method detects the back-EMF of the stator coils that’s conditioned and used to initiate the drive signals to the windings. Current-sense resistors are placed in series with the external MOSFET ½-H-bridges driving the stator windings to generate trapezoidal-shaped feedback signals processed by current-sense amplifiers (Fig. 3). This arrangement is known as field-oriented control (FOC).

With FOC algorithms implemented in the MCU, the BLDC motor runs more efficiently with higher power factor and quicker response to dynamic load or speed changes.

The DRV832x and DRV835x drive families give designers the flexibility to choose a device that meets architecture requirements, including FOC. Use the following link to access more details.

Sponsored Resources:

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.