This file type includes high-resolution graphics and schematics when applicable.

Piezoelectricity was discovered by two French scientists’ brothers, Jacques and Pierre Curie, in 1880. They found out about piezoelectricity after first realizing that pressure applied to quartz or even some certain crystals creates an electrical charge in that certain material.1 They later referred to that strange and scientific phenomenon as the piezoelectric effect.

The Curie brothers soon discovered the inverse piezoelectric effect. It was after they verified that when an electric field was enforced onto crystal leads, it led to the malformation or disorder to the crystal lead—now called the inverse piezoelectric effect.

The term piezoelectricity comes from the Greek word piezo meaning to squeeze or press. Interestingly, electric in Greek means amber. Amber also happened to be a source of electrical charge.2

Many electronic devices today use piezoelectricity. For example, when you use some type of voice-recognition software, or even Siri on your smartphone, the microphone that you’re speaking into is probably using piezoelectricity. That piezo crystal turns the sound energy in your voice, and changes it into electrical signals for your computer or your phone to interpret.3 That all becomes possible with piezoelectricity.

The creation of various more-advanced technologies can be traced to discovery of piezoelectricity. For example, the powerful sonar “sonobuoy” small sensitive microphones, and the ceramic audio tone transducer, were made possible by piezoelectricity. Today we’re seeing the development of ever-more piezoelectric materials and devices.

The piezoelectric effect is the ability of certain materials to generate an electric field in response to applied mechanical stress. Those materials include crystals, ceramics, polymers, wood (cellulose fibers), and a host of other synthetic and composite materials. Initially discovered in 1880 by the Curie brothers, the piezoelectric effect has found its way into everyday electronics we rely on for everyday use, including smartphones, laptops, sensors, LEDs, and more.

Some of these devices, like the electronic toothbrush, use piezoelectricity to create physical vibrations, which causes the toothbrush to vibrate and makes it easier to clean your teeth. The same with the microphone in a smartphone, which translates the sound from a person’s voice into electronic signals that can be read by an embedded processor to interact with certain apps and functions.

Piezoelectricity can be used in a variety of ways, including sensing change in pressure, force, and temperature. Generating electricity by converting motion into energy, producing ultrasonic sounds, controlling acoustics in speakers, and even generating electrical signals in pacemakers are just a few examples of how piezoelectricity can be harnessed.

Direct Piezoelectric Effect

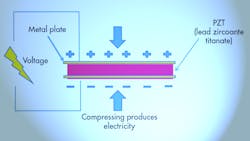

As stated, compressing a piezoelectric material produces electricity (piezoelectricity). Figure 1 explains the concept.

Piezoceramic material—non-conductive piezoelectric ceramic or crystal—is placed between the two metal plates. For piezoelectricity to be generated, it needs that material to be compressed or squeezed. Mechanical stress applied to piezoelectric ceramic material generates electricity.

As shown in Fig. 1, there’s a voltage potential across the material. The two metal plates sandwich the piezo crystal. The metal plates collect the charges, which creates/produces voltage (lightning bolt symbol), i.e., piezoelectricity. In this way, the piezoelectric effect acts like a miniature battery, because it produces electricity. This is the direct piezoelectric effect. Devices that use the direct piezoelectric effect include microphones, pressure sensors, hydrophones, and many other sensing types of devices.

Inverse Piezoelectric Effect

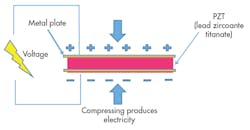

The piezoelectric effect can be reversed, which is referred to as the inverse piezoelectric effect. This is created by applying electrical voltage to make a piezoelectric crystal shrink or expand (Fig. 2). The inverse piezoelectric effect converts electrical energy to mechanical energy.

Using the inverse piezoelectric effect can help develop devices that generate and produce acoustic sound waves. Examples of piezoelectric acoustic devices are speakers (commonly found in handheld devices) or buzzers. The advantage of having such speakers is that they are very thin, which makes them useful in a range of phones. Even medical ultrasound and sonar transducers use reverse piezoelectric effect. Non-acoustic inverse piezoelectric devices include motors and actuators.

Piezoelectric Materials

Piezoelectric materials are materials that can produce electricity due to mechanical stress, such as compression. These materials can also deform when voltage (electricity) is applied.

All piezoelectric materials are non-conductive in order for the piezoelectric effect to occur and work. They can be separated into two groups: crystals and ceramics.4

Some examples of piezoelectric materials are PZT (also known as lead zirconate titanate), barium titanate, and lithium niobate. These man-made materials have a more pronounced effect (better material to use) than quartz and other natural piezoelectric materials.

Compare PZT to quartz. PZT can produce more voltage for the same amount of applied mechanical stress. Conversely, applying voltage to PZT instead of quartz provides more movement. Quartz, a well-known piezoelectric material, is also the first known piezoelectric material.

PZT is created and produced (under high temperatures) with two chemical elements—lead and zirconium—and combined with a chemical compound called titanate. PZT’s chemical formula is (Pb[Zr(x)Ti(1-x)]O3). It is commonly used to produce ultrasounds transducers, ceramic capacitors, and other sensors and actuators. It also evinces a special range of different properties. In 1952, PZT was manufactured by Tokyo Institute of Technology.5

Barium titanate is a ferroelectric ceramic material with piezoelectric properties.6 For that reason, barium titanate has been used as a piezoelectric material longer than most others. Its chemical formula is BaTiO3. Barium titanate was discovered in 1941 during World War II.7

Lithium niobate is a compound that combines oxygen, lithium, and niobium. Its chemical formula is LiNbO3.8 Also a ferroelectric ceramic material it’s just like barium titanate in that it has piezoelectric properties, too.9

Piezoelectric Devices

Sonar

Sonar, which arrived in the 1900s, was invented by Lewis Nixon. He initially developed sonar to help detect icebergs. Interest in sonar rose during World War I, though, to help locate submarines underwater. Of course, sonar has many purposes and uses today, from locating fish to underwater navigation and so on.

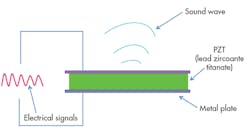

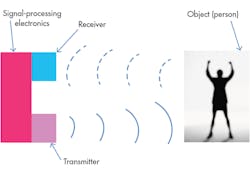

In Figure 3, sonar is sending out, via transmitter, a sound wave (signal) to search for objects ahead. The transmitter uses inverse piezoelectric effect, which is when the transmitter will use voltage to help it send out a sound wave. Once the sound wave hits an object, it will bounce back. The sound wave that bounces back will be detected by the receiver.

The receiver, unlike the transmitter, uses the direct piezoelectric effect. The receiver piezoelectric device gets compressed by the returning sound wave. It sends the signal (voltage) to the signal-processing electronics, which will take that bounced-back sound wave and begin processing it. It will determine the object’s distance by calculating the timing signals from the transmitter and the receiver.

Piezoelectric Actuators

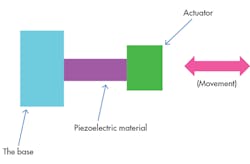

Figure 4 shows the operation of a piezoelectric actuator. The base stays still and acts like the metal plate that sandwiches the middle piezoelectric material. Then voltage is applied to the material, which expands and contracts from the applied voltage’s electric field. The piezo crystal moves very little, whether forward or backward. Once the piezo material or crystal moves, it slowly pushes and pulls the actuator.

The piezoelectric actuator has many uses and applications. For example, knitting machinery and braille machines use these actuators, since they have such a small amount of moving parts and a very simple design. They can even be found in video cameras and cellular phones, because they are proven most proficient as an auto-focusing mechanism.10

Piezoelectric Speakers and Buzzers

Piezoelectric speakers and buzzers use the inverse piezoelectric effect to generate and produce sound. When voltage is applied to speakers and buzzers, it creates sound waves (Fig. 2, again). An audio voltage signal applied to the piezoelectric ceramic of speakers or buzzers will cause the material to vibrate the air. That vibration produces sound waves, which come out of the speaker.

Piezoelectric speakers are commonly used in alarm clocks or other small mechanical devices to generate simple, high-quality audio sounds. That’s because they are limited to a small amount of frequency response.11

Piezo Drivers

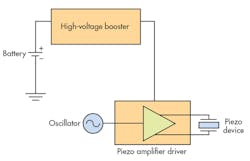

Piezo drivers can convert low battery voltage into high voltage to power piezoelectric devices. Piezo drivers are very important, because they help engineers produce more voltage to create larger sine waves.

Figure 5 is a block diagram that illustrates piezo-driver operation. Piezo drivers will take low battery voltage and use a booster to convert it to higher voltage. The higher voltage is then used to power the amplifier. The oscillator will input small sine waves, which the amplifier will change into larger voltage sine waves. The amplifier drives the piezo device.

The table below lists of several different companies that sell and produce various kinds of piezo drivers.

Conclusion

What does the future hold for piezoelectricity, and what might that future look like? One of the more popular ideas is to utilize the effect for energy harvesting. Imagine charging smartphones while walking or exercising with the same efficiency as rapid charging. Embedding piezoelectric systems underneath roads and highways could power infrastructure such as city and traffic lights. It could even be used as ultrasonic motors for advanced optics, medical sensors within the body, and electricity-generating tires.

The future of piezoelectricity is very promising. This technology is constantly evolving and becoming more efficient and less expensive. There are many potential applications for piezoelectricity, and it's expected that this technology will continue to grow in popularity in the years to come.

Originally published September 16, 2016.

References

1. http://www.piezo.com/tech4history.html

2. https://en.wikipedia.org/wiki/Piezoelectricity

3. http://www.explainthatstuff.com/piezoelectricity.html

4. http://www.piezomaterials.com/

5. https://www.americanpiezo.com/piezo-theory/pzt.html

6. https://en.wikipedia.org/wiki/Barium_titanate

7. http://ceramics.org/wp-content/uploads/2009/03/elec_division_member_papers1.pdf

8. https://en.wikipedia.org/wiki/Lithium_niobate

9. http://www.inradoptics.com/products/non-linear-crystals/lithium-niobate-linbo3

10. https://www.americanpiezo.com/piezo-theory/actuators.html