Wood as a Transducer for Energy Harvesting of Low-Grade Heat?

>> Website Resources

.. >> Library: TechXchange

.. .. >> TechXchange: Power Management

.. .. .. >> Topic: Energy Harvesting

Although it may seem counterintuitive to even consider wood as having a functional role in electronics, researchers demonstrated that it’s possible to use extensively modified wood as the transducer for harvesting useful energy from low-grade (also called low temperature) sources such as body heat. A team based at the University of Maryland has transformed this common material so that it can use a low temperature value to efficiently generate ionic voltage.

Of course, it’s not a simple process, nor is the final appearance of the wood close to its original state, as if it was just cut from a tree or a beam. Wood consists of three main components: cellulose (which turns the wood brown and makes it stiff and strong), hemicellulose (which winds around the layers of cells and binds them together) and lignin (complex polymers that give woody plants structure, strength, and rigidity).

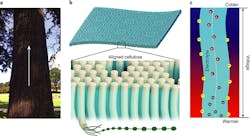

To produce a cellulose-based membrane, they chemically extracted the lignin and dissolved the hemicellulose from the wood. After this treatment, the naturally aligned cellulose nanofibers were the remaining component of the wood structure (Fig. 1). (The researchers used basswood, which is a fast-growing tree with low environmental impact.)

1. Schematic of the ionic conductor composed aligned cellulose nanofibers: The cellulose fibers are naturally aligned along the tree growth direction (white arrow) (a). Cellulose exhibits a hierarchical alignment, where the nanofibers consist of aligned cellulose molecular chains (b). Schematic of the ionic device after infusing (infiltrating) electrolyte into the nanofluidic cellulosic membrane (c). Under a thermal bias (temperature differential), the surface-charged nanofibers regulate ionic movement via nanofluidic effects (the overall effect created by a high degree of confinement and the charged walls of the cellulose nanochannels).

They next infused (what they call “infiltrated”) this cellulosic membrane with NaOH (sodium)-based electrolyte to construct a nanofluidic, ionic conductor of aligned tubes, which was then sandwiched between two platinum electrodes for testing purposes. By imposing a temperature difference across the membrane, they were able to develop a differential thermal voltage.

The team reported a thermal gradient ratio (analogous to the Seebeck coefficient of thermoelectricity) of 24 mV/K, which they maintain is more than twice the highest value previously reported. The differential thermal voltage originates from the ionic selectivity of the negatively charged cellulose nanofibers and the resulting development of surface-charge-governed ion transport, where a natural asymmetry numerical density of positive and negative ions occurs in the nanochannel.

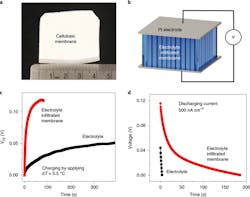

For evaluation, the sealed device was exposed to an external temperature difference of 5.5°C and the charging/discharging behavior was compared against those parameters of the bulk electrolyte (Fig. 2). The electrolyte-infused cellulosic membrane (red curve) was charged to 0.118 V with a response time of ~70 seconds, while its bulk counterpart (black curve) was charged to 0.050 V with a much longer response time of ~380 seconds.

2. Thermal charging behavior of the electrolyte-infiltrated cellulosic membrane: Digital image of the oxidized, aligned cellulosic membrane (a). Schematic of the testing setup for the nanofluidic ionic device, where the oxidized cellulosic membrane is infiltrated with polymer electrolyte and sandwiched between two platinum electrodes (b). Charging (c) and discharging (d) behavior of the polymer electrolyte with and without the oxidized cellulosic membrane.

As with most electrochemical processes, scalability and manufacturing are major challenges. Nanofluidic devices are typically fabricated either via a sequence of bottom-up assembly of low-dimensional structures or top-down nanolithography to pattern nanochannels. The researchers say that their approach avoids these costly micro/nanofabrication processes by using the naturally aligned cellulose nanofibers of wood.

To demonstrate the scalability to some extent, they fabricated a 10 × 10 cm2 nanofluidic membrane that remained flexible largely due to the inherent properties of wood. Their process could enable low-grade energy harvesting of electricity from body heat when wrapped around a hand, as one example.

The work is presented in their paper “Cellulose ionic conductors with high differential thermal voltage for low-grade heat harvesting” published in the journal Nature Materials (behind a paywall, but an open-access copy is available here). There’s also an array of published Supplementary Information material. The actual benefits of using extensively processed wood as a basis for an energy-harvesting transducer may not be immediately clear, but the project and its results are certainly thought-provoking.

>> Website Resources

.. >> Library: TechXchange

.. .. >> TechXchange: Power Management

.. .. .. >> Topic: Energy Harvesting

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.