Test Systems: Hands-off testing key to ICs and solar

If you wanted to learn about automated test equipment (ATE) but only had a couple of days in which to do so, how would you spend your time? Certainly, there’s a lot of material online, but for sheer information-overload, you can’t beat attending major trade shows.

This year’s SEMICON West Business and Technology Conference and Expo boasts about 700 exhibitors and has been established the longest of the four shows running simultaneously July 12-14 at San Francisco’s Moscone Center. The largest of the other three, InterSolar North America, anticipates hosting an additional 550 exhibitors. Co-located with InterSolar are SOLAR 2016, the American Solar Energy Society’s conference; and the Electrical Energy Storage (ees) North America show, which last year hosted 74 exhibitors.

According to a press release issued by the InterSolar and ees show organizers, “The ees exhibitions and accompanying conferences are focused on storage solutions for renewable energy, from residential and commercial applications to large-scale storage systems for stabilizing the grids. ees also features energy management, electric transportation, and uninterruptible power supplies.”

Automation has long been associated with semiconductor manufacturing and is well-represented at this year’s SEMICON West. Test systems have many facets extending from initial wafer handling and probing to final test with burn-in, and they all use ATE. Moving up the food chain from individual devices to assemblies, automated test of a different type addresses the inverters and energy storage products associated with solar power.

Semiconductor manufacturing

As the SEMICON West website states, “Everything is changing…. SEMICON West has been retooled to keep pace with the industry’s realignment. It’s built around disruptive trends driving the market…. We’ve deepened our reach across the full electronics manufacturing supply chain to connect you with more key players….” Smart manufacturing is one of the trends specifically mentioned.

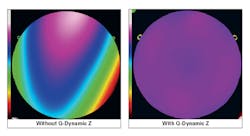

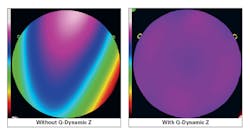

Addressing silicon wafer defect detection, Sonoscan has developed the Quantitative Dynamic-Z surface tracking feature (Figure 1) for scanning warped wafers. According to a press release, “The tool acquires data from the scans that not only reveals the features inside the wafer, but also measures the warpage. The warpage information is used during the scan to instantly adjust the height of the transducer above the wafer surface and maintain the critical focus inside the wafer over its entire area.”

Courtesy of Sonoscan

Moving on to device testing, National Instruments (NI) will be highlighting the Semiconductor Test System (STS) in its three configurations: T1 with one 18-slot PXI chassis, T2 with two chassis, and T4 with up to four 18-slot PXI chassis internally. All STS models use NI’s TestStand test executive software. An STS brochure explains, “Its ‘tester in a head’ design houses all the key components of a production tester including system controllers; DC, AC, and RF instrumentation; device under test (DUT) interfacing; and device handler/prober docking mechanics.” This means the STS is equally adept at wafer sort or final test after dicing and packaging.

The brochure continues, “The STS is available with RF port expansion modules for multiport RF test. The core of this subsystem is the vector signal transceiver (VST), which provides up to 200 MHz of real-time bandwidth for RF signal generation and analysis.” Multiple VSTs can be configured to test a broad range of RF ICs, such as RF front-end ICs and RF MEMS devices.

NI and Optimal+, a global big-data-analytics provider for the semiconductor industry, have collaborated to enable the entire suite of solutions from Optimal+ to be supported by NI’s STS via the Optimal+ Proxy.

The Proxy is a full-featured agent with the capability to acquire test data events in real time, independent of the test datalogging format or system. From a control perspective, Proxy is able to send control commands to TestStand to adaptively resequence tests to achieve the best possible throughput while maintaining full test coverage. Running in the background of the STS, the Optimal+ Proxy gives users the power of adaptive testing, escape prevention, real-time data analytics, and globally consolidated data.

NI’s Ron Wolfe, vice president of semiconductor test, said, “With each new deployment, the NI STS continues to prove its capability to lower costs and decrease time to market. Helping customers gain additional value and insight from their test data through the collaboration with Optimal+ is a natural complement to NI’s open, platform-based approach.”

Also exhibiting a tester, Marvin Test Solutions will be showing its PXI-based TS-900 Series product line, which includes the TS-960 semiconductor test platform. Featuring the GX5296 PXI digital subsystem, the TS-960 offers subnanosecond edge placement, timing per pin, multiple time sets, and a PMU per pin—making the TS-960 suitable for both digital and mixed-signal test applications. The TS-960 supports up to 512 high-performance digital channels in a single chassis, and its compact footprint and receiver interface easily adapt to handler/manipulator configurations.

With the release of the TS-960, MTS has upgraded the company’s software tools for semiconductor test to include:

- expanded file translation tools that support popular digital files formats including STIL, VCD/eVCD, WGL, and Teradyne’s ATP format;

- advanced waveform display and edit tools supporting the features of the GX5296 digital subsystem;

- automated TDR pin deskew tool; and

- enhanced shmoo tool (part of MTS’ ICEasy test library) supporting the features of the GX5296.

Featuring RF capabilities, Roos Instruments will be exhibiting the Casini 16 ATE test system (Figure 2) complete with 40-, 60-, and 80-GHz high-frequency instruments. With 16 instrument slots, the Casini 16 supports typical power amplifier test requirements with four independent DC supplies, a 10-MHz to 20-GHz digitally modulated RF source in an auxiliary rack, an RF/microwave receiver with 50-MHz to 20-GHz time- and frequency-domain capture, a 4-GHz to 40.5-GHz power measure/multiport VNA, and a 0 to 20-GHz RF combiner for RF mixing in multitone tests. Other common configurations address transceiver, SoC, automotive radar, cellular infrastructure, and military aerospace applications.

Courtesy of Roos Instruments

For manufacturers with unusual test needs or for those that prefer to construct their own test systems, switching is an essential part. Pickering Interfaces will be exhibiting new products within its Series 40-760 50-Ω, 600-MHz PXI RF multiplexers. Available configurations include dual, quad, and octal SP4T; single, dual, and quad SP8T; single and dual SP16T; and single SP32T. All of the multiplexers have versions with automatic terminations to manage VSWR effects, which could degrade the performance of a test system. Each version exhibits low insertion loss and VSWR through the use of modern RF relay technology, with each path having a nominally equal insertion loss.

Also on display will be the new 40-520 family of one-pole high-density PXI matrix modules. There are 22 different configurations and up to 256 crosspoints to suit a large variety of user requirements. The choice of six bus widths (x16, x12, x8, x6, x4, x2) enables competitively priced solutions. All models use Pickering Electronics’ instrumentation-quality reed relays, which offer very long life with good contact resistance stability and low-level switching performance. The modules come with built-in relay self-test (BIRST) and the company’s eBIRST switching system test tools.

Burn-in with test systems provide an important step in the manufacture of high-reliability parts, and Micro Control will likely exhibit one or more of its products. For the LC-2 Logic and Memory Burn-in System, up to 64 burn-in boards (BIB) can be powered with each DUT having individual temperature control with up to 50-W dissipation. With 16 user-defined pattern and power zones, different tests as well as different device types can be accommodated.

The HPB-5C increases the allowable power dissipation per DUT to 150 W maximum and the amount of test vector memory available per DUT to 32M. A total of 384 devices can be tested at temperatures up to 150°C with an 800-MHz clock rate. The HPB-4A increases the maximum power per device to 600 W and includes a liquid-cooled heatsink for each DUT. A total of 112 devices can be tested—eight devices on each of 14 BIBs, each BIB capable of providing 2,060 A. This model also features programmable clocks with leading and trailing edges per pin, 1-ns resolution, and eight on-the-fly timing sets.

PV-related test at InterSolar

The efficiency of any system is defined as the ratio of the output to the input. For PV installations, the input is the direct normal irradiance (DNI)—the solar radiation arriving at the earth’s surface. According to a Campbell Scientific white paper,1 “… [DNI] is a difficult parameter to measure and one of the most expensive measurements in the field of broadband solar and infrared radiation measurements.”

The company’s CR6 smart datalogger was programmed to perform a multistep calibration routine of an Eppley AHF cavity radiometer. After calibration, the automated test routine measured DNI values. As the white paper explains, “The calibration time is four min; series measurement time is 21 min; and the time interval between measurements is 30 s. This means a user can collect up to 42 solar irradiance measurements every 25 min.”

Campbell also features a range of solar monitoring stations, such as the Solar1000-SCE shown in Figure 3, typically used by solar energy producing utilities and based on the company’s CR6 measurement and control datalogger. The unit features an uninterruptable power supply and sensors for air temperature, relative humidity, diffuse radiation, total global plane of array irradiation, total global horizontal irradiation, solar altitude and azimuth angle, precipitation, and back of module temperature. Communications choices such as TCP/IP, RS-485, fiber, cellular, satellite, and radio are supported. Although offered as a turnkey unit, almost all aspects of the Solar1000-SCE are customizable.

Courtesy of Campbell Scientific

Electricity produced by a PV installation has to be consumed on the power grid or stored. With products that address both aspects, NH Research is likely to feature the 9200 Series Test System that can be used to emulate any energy storage system and the 9410 Grid-Simulator, which is used to verify a product’s AC performance.

The NHR 9410 Grid Simulator can provide a 1Φ, 2Φ, or 3Φ simulated utility connection while allowing per-phase controls for amplitude, wave shape, and the relative phase angle relationship. These features allow testing of any number of AC conditions including phase imbalance, voltage sag, frequency changes, and harmonic injection. The integral measurement system removes the need for additional power meters, DMMs, oscilloscopes, or spectrum analyzers.

The 9200 Battery Test System features a charge mode, a discharge mode, and a battery emulation mode, allowing a battery to be tested or electronically emulated. Because battery emulation replaces a real battery, it avoids risks associated with a battery failure and facilitates faster and more consistent testing by eliminating battery-related preparation time, operator errors, and result variations due to temperature or aging.

Reference

- Singh, A. and Perry, M., Development of a new controller for absolute cavity, cavity calibration, and solar irradiance measurement, Campbell Scientific, White Paper, September 2015.

For more information

About the Author