January 2020 Industry Report

ADLINK Teams with Intel and AWS to Offer AI at the Edge

The ADLINK AI at the Edge solution closes the loop on the full cycle of machine-learning model building—from design to deployment to improvement—by automating edge-computing processes so that customers can focus on developing applications. The ADLINK AI at the Edge solution features:

Intel Distribution of OpenVINO toolkit, which optimizes deep learning workloads across Intel’s architecture;

Amazon Sagemaker, a fully managed service that covers the entire machine learning workflow;

AWS Greengrass, which extends AWS to edge devices so they can act locally on the data they generate, while still using the cloud for management, analytics, and durable storage;

The ADLINK Data River, offering translation between devices and applications to enable a vendor-neutral ecosystem; and

The ADLINK Edge software suite, which builds a set of deployable applications to communicate with end-points, devices, or applications.

“We’ve worked on multiple industrial use cases that benefit from AI at the edge, including a smart-pallet solution that makes packages and pallets themselves intelligent so they can detect where they’re supposed to be, when they’re supposed to be there, in real-time,” said Toby McClean, VP, IoT Innovation & Technology, at ADLINK. “This enables warehouse customers to yield improved logistics and productivity, while also decreasing incorrectly shipped packages and theft. And this use case can be replicated across verticals to improve operational efficiency and productivity.”

The EMC Shop acquires Arris facility, launches testing & design division

The EMC Shop has acquired the facility, test chambers, and talent of the former ARRIS facility in Nevada City, CA, thereby allowing The EMC Shop to offer services for testing DFS (essential for 5 GHz Wi-Fi), EMC, antenna pattern measurement, and environmental product evaluation necessary for regulatory compliance. In addition, design, development and testing services for antennas and embedded Wi-Fi products are also available. A fully anechoic 3-m chamber, antenna test chamber, and other enclosures will allow The EMC Shop to immediately provide the above test and design services.

The talent and experience that was retained from ARRIS include an EMC test engineer, a hardware design engineer, an antenna design engineer, a test engineer, and a software engineer. Each engineer will support the core business of The EMC Shop, provider of custom test solutions, as well as the Testing & Design Division.

Utilizing test systems and assets from The EMC Shop’s Roseville location, testing capabilities already include RF and electromagnetic immunity and emissions testing for automotive, commercial, medical, military, and aerospace products. The devices under test can be up to 1 m3 in size, with power handling capacity supported up to 100 A, 3 Phase. Utilizing the experience of ARRIS engineers, customers are able to make in-lab adjustments and re-design to get the most out of their lab time.

Companies join forces to advance integrated photonics

Keysight, FormFactor, and CompoundTek have jointly developed an advanced photonics on-wafer testing solution that delivers industry-first capabilities including automated alignment as well as simultaneous optical-optical and optical-electrical device tests.

The joint solution, to be offered by CompoundTek, includes

Keysight’s PathWave software platform, which provides a consistent user experience as well as common data formats and control interfaces; and

FormFactor’s SiPh software that enables automated calibrations and alignments and simplifies integration with Keysight’s PathWave software platform, as well as optical instrumentation, to ensure ease of use.

Silicon photonics also delivers benefits for industrial segments such as intra-datacenter communication and datacenter interconnects (DCI), telecom, 5G and automotive connectivity, high-performance computing, light detection and ranging (lidar), as well as sensing and medical applications.

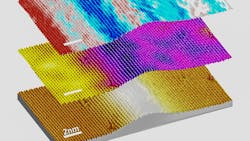

Scientists discover ‘ripple’ in flexible material that could improve electronic properties

Two-dimensional materials—those either only an atom or layer thick—display a number of interesting properties and could form the foundation for a range of new devices. One of these materials, molybdenum disulfide (MoS2), has shown an unusual flexibility that could make it attractive as a semiconducting component of bendable electronics.

After straining a film of the material grown on graphite, the researchers noticed that the formerly two-dimensional sheet of MoS2 would slip, relaxing the strain. This, in turn, formed a rippled pattern at a larger scale that translated into an altered electronic structure within the individual atoms.

“You can think of it like stretching a rubber band,” said Argonne nanoscientist Saw-Wai Hla, an author of the study. “After you release the tension, the rubber band snaps back together even more tightly than its initial position.”

The ripple pattern remains after the strain is removed and leaves the material looking like a rug that has been bunched up as the material loses its total two-dimensionality. Introducing the ripple through strain could be either deleterious or helpful to the functioning of an actual flexible electronic device, according to Hla, who explained that while an unintentional strain relaxation would likely impair the material, a directed strain response could achieve precisely targeted electronic behavior in MoS2.

A paper based on the study, “The effects of atomic-scale strain relaxation on the electronic properties of monolayer MoS2,” appeared in the July 3 issue of ACS Nano. Additional collaborators on the study included Argonne’s Yuan Zhang and Temple’s Fabrizio Bobba, Xiaoxing Xi, and Maria Iavarone.

AR enters agreement with NEXIO in North America for EMC solutions

Amplifier Research (AR) announced that it has added a significant component to its offerings for the EMC market. The company said it has been appointed an exclusive distributor of NEXIO products and services when incorporated as part of a turnkey solution. With the addition of this suite of NEXIO products, AR said, it is now a 1-stop total solutions provider for the electromagnetic compatibility testing market.

As a specialist in EMC and RF testing, NEXIO serves laboratories worldwide in the commercial, automotive, and aerospace and defense market sectors with a range of test automation software, EMC test engineering, and simulation-analysis services.

“The arrangement with AR represents the first step to global collaboration. NEXIO is excited to participate in an alliance consisting of industry-leading companies working together to deliver optimal customer solutions,” explained Frederic Amoros-Routie, president of NEXIO.

Cadence, NI enter into strategic alliance agreement

National Instruments on Dec. 2 announced a “system innovation strategic alliance to create an integrated design-to-test flow, leveraging reusable data and test IP from electronics design and verification to validation and production test for electronic system and semiconductor companies.” The expressed intent in a press release from National Instruments is “to provide customers with a seamless flow from pre-silicon development to post-silicon test, leveraging design, verification, and analysis data between Cadence and NI technologies.”