The urgency for change: Are traditional DRC debug flows enough?

Physical verification engineers know all too well the reality of debugging massive integrated circuit (IC) designs. For years, the physical verification process—including design rule checking (DRC)—has been a labor-intensive, iterative cycle. With every process node shrink and every new design architecture, the number and complexity of DRC errors multiply, so even the brightest engineering teams can feel like they're drowning in violations.

Traditional tools deliver thousands to millions of errors in large, plain-text files. Engineers manually sort through unwieldy results, hoping to find real root causes among endless repetitions and exceptions. This approach is increasingly unsustainable.

Today’s advanced nodes and 3D IC integration demand not just more checking, but smarter checking. That’s where artificial intelligence-driven debug solution steps in. The Calibre Vision AI tool from Siemens EDA is more than an incremental upgrade. It represents a fundamental shift, empowering engineers to triage the full-chip DRC results rapidly, and distributing the workload to the block owners.

Classic DRC debug: Manual, repetitive, and slow

To appreciate the impact of Calibre Vision AI, let’s revisit the classic debug cycle. An initial DRC run generates an ASCII file, usually with a limited number of violations flagged to control the file size. Engineers spend days, even weeks, wading through errors, categorizing, cross-referencing and deciding what to fix first. This approach is tedious and prone to overlooking critical root causes, especially when error patterns are buried in noise. Figure 1 illustrates the traditional DRC debug cycle using Calibre tools.

Figure 1. The classic DRC debug cycle, highlighting the overwhelming flow of raw error data.

Designers can continue using RVE/ASCII for final or block-level debug but now leverage Calibre Vision AI and OASIS for “dirty” SoC-level passes, when violation counts overwhelm manual or script-based processes. This flexibility ensures teams always have the right tool at each verification stage.

Calibre Vision AI redefines the full-chip DRC workflow

Calibre Vision AI dramatically compresses and organizes errors using AI algorithms. Instead of handing off a raw list of violations, Calibre Vision AI sorts billions of errors into prioritized Signal groups—each representing a unique pattern or class of issue. The AI-driven approach isolates root causes, highlights systemic issues and provides actionable grouping for rapid resolution. Figure 2 illustrates the new workflow.

Figure 2. The Vision AI flow: Calibre nmDRC writes results to OASIS, which loads in seconds into Vision AI’s GUI. Designers use AI-guided Signal analysis to focus on systemic issues.

Unleashing the power of prioritized Signals

The secret to the productivity boost is the use of “Signals”—intelligent groupings of related error data. Calibre Vision AI identifies and categorizes seven core Signal types using AI-guided pattern recognition. These include layout hotspots, systematic layout context issues, design rule pattern clusters and others. By navigating error review by Signal rather than individual violations, engineers can understand underlying causes in minutes and eliminate whole classes of errors at once.

Signal types include broad groupings—likeFailsEverywhere and FailsLocally—that help designers quickly recognize systematic problems or isolated hotspots.. Four of the seven groups are further categorized as Signature Signals, capturing recurring failure patterns across the die. Level1 and Level2 groups are created using spatial and density unsupervised clustering techniques, leading to very tight check clusters that target specific root causes Figure 3 shows the seven Signal groups.

Figure 3. Signal types in Vision AI reflect dominant check patterns and failure characteristics.

Real-world transformation of the debug cycle

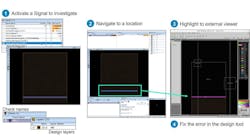

With Signals, debug becomes a streamlined, fault-finding mission rather than a hunt for needles in haystacks. Engineers step through prioritized Signal groups, visualizing the density and impact of each, and immediately navigating to associated locations in the design. Errors can be cross-probed in external design tools (such as place and route), helping engineers in quickly visualizing and addressing specific failures in the golden design database—closing the loop between analysis and fixing. Figure 4 shows how Signal-guided debug works.

Figure 4. Signal-guided fixing with Vision AI: from analysis in the GUI, highlight issues in the design tool, and accelerate iterative closure.

This approach turns the debug process from a slow marathon into a focused sprint. Instead of wasting days jumping from violation to violation, teams can resolve entire groups of related errors in one pass, leading to faster time-to-fix and a sharper path to signoff.

Proven results at scale

Calibre Vision AI has proven its value at scale with production-ready deployment across advanced IC projects. In measured flows, the error result files are fifty times smaller than with legacy workflows—while including five times the number of errors and loading in under a minute. These outcomes mean less time wasted on file parsing, dramatically reduced memory and storage demands, and a reduction in DRC iteration through AI-assisted debug.

Physical verification teams adopting Calibre Vision AI can outpace silicon complexity. More errors caught early, more time freed for engineering innovation, and fewer late-stage surprises. All this while integrating seamlessly into established Siemens EDA flows and 3rd party design tools—no disruption, only acceleration.

Pioneering the AI evolution in EDA

Calibre Vision AI does not operate in isolation; it is part of a broader trend—Siemens EDA uses industrial-grade generative and agentic AI across its toolset for semiconductor design. In this system, AI acts less as a bolt-on aid and more as a fundamental enabler of next-generation design. As IC design moves further into system-of-systems, heterogeneous integration and aggressive time-to-market demands, engineers need AI as a trusted collaborator—amplifying insight, not just automating routine work.

Calibre Vision AI is leading this revolution for DRC debug. It offers physical verification engineers and design teams a chance to reset expectations: by moving past brute-force error review and jumping forward to intelligent, scalable verification workflows. The key result for users is the ability to find and fix critical design violations in half the time of existing methods.

The future of IC physical verification is AI-driven—and it’s here today

While no physical verification flow comes with an “easy button”, Calibre Vision AI provides value to design teams by enabling radically faster throughput. As yesterday’s debug limits give way to AI-powered insights and workflows, engineers can finally keep pace with their silicon ambitions. The era of smarter physical verification has arrived.

About the Author

James Paris

James Paris is a Principal Product Engineer at Siemens EDA focused on Calibre Vision AI

Priyank Jain

Priyank Jain is a Product Manager at Siemens EDA overseeing Calibre interface products.