E-Glove for Prosthetic Hand Senses Pressure, Temperature, Moisture—and Warms Itself

A conventional prosthetic hand may enable functions such as the ability to grip, but it lacks qualities of softness, warmth, appearance, and sensory perception, including detection of pressure, temperature, and hydration. To improve the cold, unfeeling hand, a team based at Purdue University in collaboration with researchers at the University of Georgia and the University of Texas developed a slip-on flexible electronic glove (e-glove) that adds both sensory capabilities as well as skin-like softness and even warmth.

In the video below, project leader Chi Hwan Lee, an assistant professor at Purdue, provides an overview of the project rationale, fabrication steps, and capabilities:

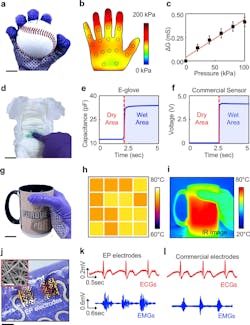

The e-glove uses thin, flexible electronic sensors and miniaturized standard ICs on standard flexible glove (Fig. 1). It’s connected to a specially designed wristwatch, allowing for real-time display of sensory data and remote transmission to the user for post-data processing.

Fabrication of the e-glove begins with a commercial stretchable nitrile glove, layered with an adhesive layer and active sensing elements, and with a screened-on mesh of silver threads for conductivity (Fig. 2). Other layers were added, including an elastomer silicon layer for skin-like “softness.”

Some of the steps were repeated to stack multiple layers to include different types of sensors. Among these was a capacitive hydration sensor, pressure-sensing layers, electrodes for the recording of electrocardiogram (ECG) and electromyogram (EMG) signals, and temperature sensors. They also incorporated a scheme that uses the stretched conductive mesh for resistive heating of the glove to create a human-like warmth—an asset when shaking hands, for example.

For the wristwatch-like control unit, they used 3D printing and a tiny printed circuit board on which they mounted the microcontroller circuitry, analog components, and multiplexer. The entire structure was attached to commercial wristband using epoxy adhesive.

Among the electronic functions was a 100-μA constant-current source for the sensors, and a 32-channel multiplexer used to switch among sensors while the voltage drop is measured across the elements. The changes in the sensed voltages—corresponding to external stimuli such as pressure, temperature, and more—were measured by a 16-bit analog-to-digital converter, displayed on the control wristwatch unit, and transmitted to an external device (commercial smartphone or tablet) via Bluetooth. The system is powered by a 3.7-V, 350-mAh rechargeable Li-ion polymer battery that provides operation between 15 hours (~71 mW dissipation with continuous display) and 70 hours (~16 mW, on-demand display only).

In addition to detailed finite element analysis (FEA) for mechanical and thermal modeling, they performed both fixture-based and real-world tests using the glove to grasp a baseball, touch a wet diaper, and handle a cup of hot water, all while monitoring the pressure exerted across the whole palm area with an array of 20 pressure sensors (Fig. 3). They also evaluated the “warmth profile” of the glove compared to a human hand.

“We developed a novel concept of the soft-packaged, sensor-instrumented e-glove built on a commercial nitrile glove, allowing it to seamlessly fit on arbitrary hand shapes,” noted Prof. Lee. “The e-glove is configured with a stretchable form of multimodal sensors to collect various information such as pressure, temperature, humidity, and electrophysiological biosignals, while simultaneously providing realistic human hand-like softness, appearance, and even warmth.”

Full details on the concept, design, modeling, simulation, fabrication, and results are provided in their comprehensive paper “Soft-packaged sensory glove system for human-like natural interaction and control of prosthetic hands,” published in NPG Asia Materials (Springer). The linked Supplementary Information provides further details and results, including a schematic and full bill of materials (BOM), plus links to several videos showing the glove in use.

Further work may even include incorporating “fingerprints” into a next-generation version. Purdue is looking to patent some of the technology and seeking partners to collaborate in clinical trials as well as experts in the prosthetics field to validate the use of the e-glove and to continue optimizing its design.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.