Flexible Electronic “Tattoo” is Versatile, Dual-Signal Heart-Monitor Patch

Modern materials science and fabrication techniques are enabling diverse avenues for innovation in the area of medical sensors that go beyond established basics. A multidisciplinary team based at the University of Texas (Austin) Cockrell School of Engineering has developed and tested a flexible, comfortable, long-lasting, piezo-driven wearable electronics tattoo (e-tattoo) that can be placed on the skin, and it captures cardiac health-related data in two ways.

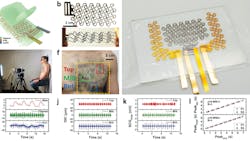

First, it captures the well-known electrocardiograph readings (ECG or EKG). Simultaneously and time-correlated, it also provides less-known seismocardiograph (SCG) readings. SCG is a measure of chest vibrations associated with heartbeats and provides additional information. When combined with ECG data, it helps assess the accuracy of the ECG readings. “We can get much greater insight into heart health by the synchronous collection of data from both sources,” noted project leader Nanshu Lu, an associate professor in the departments of Aerospace Engineering and Engineering Mechanics and Biomedical Engineering.

The e-tattoo made of polyvinylidene fluoride, a piezoelectric polymer, is remotely powered by a smartphone. The UT team claims it’s the first ultra-thin and stretchable technology to measure both ECG and SCG. Furthermore, although it’s not the first ECG-sensing tattoo, the others are fabricated from non-stretchable materials, making them bulky and uncomfortable for wear beyond short periods. This sensor can be worn for several days while providing constant heart monitoring, a major advantage over brief, “at the doctor” hookups and readings.

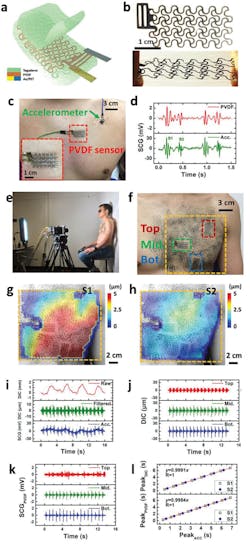

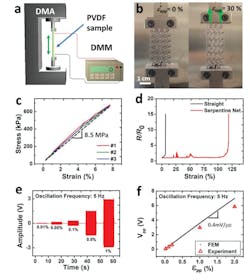

The sensing patch consists of a 28-μm-thick polyvinylidene fluoride (PVDF) film with 80-nm thick Cu-Ni electrodes on the top and bottom surfaces. This piezoelectric polymer was patterned into a serpentine mesh by a mechanical cutter plotter for a final mesh size of 38.1 mm × 18.1 mm (Fig. 1). To test the patch itself and establish baseline specifications for applied stress versus resultant strain output, they used a tensile-testing load frame and instrumentation (Figs. 2 and 3).

The project involved more than just fabricating a sensor and attaching it to a subject’s chest area. Piezoelectric sensors are subject to unwanted motion artifacts (which appear as noise), so the team minimized those by using a pair of identical tattoos placed adjacent to each other and then looking at their difference, in effect filtering out the common-mode signal (Fig. 4).

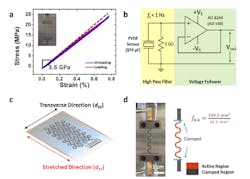

Even placement of the e-tattoo is an issue, so they painted the chest of an adult male with a random speckle pattern (using a pet brush!) and used a pair of cameras set at a 30-degree angle to capture the surface of the chest for 16 seconds at a 500-Hz frame rate. Three independent PVDF e-tattoos were attached at different locations on the chest to determine the location dependency and optimum placement of the ECG/SCG sensor.

Full details on the project, including rationale, principles, materials, fabrication, electrical schematic diagrams, test arrangements, captured waveforms, processing algorithms, and analysis of results are in their paper “A Chest-Laminated Ultrathin and Stretchable E-Tattoo for the Measurement of Electrocardiogram, Seismocardiogram, and Cardiac Time Intervals” published in Advanced Science (Wiley), along with a Supporting Information posting. The research was funded by the Office of Naval Research, the Air Force Office of Scientific Research, the National Science Foundation, the National Institutes of Health, and Texas Health Catalyst at Dell Medical School.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.