“Linear” PTC Thermistors Overcome NTC Temperature-Sensing Shortcomings

Temperature is the most widely measured physical variable and designers have many sensing options, among them thermocouples, RTDs, solid-state current-output sensors, and thermistors, to cite just a few. Among these, negative-temperature-coefficient (NTC) thermistors are widely used for temperature sensing in industrial, automotive, medical, instrumentation, and consumer applications due to their low cost, wide range, and relative ease of interfacing.

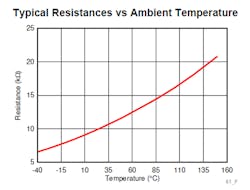

However, NTC thermistors do have well-known drawbacks. Along with their large temperature coefficient of resistance (good), they have a highly nonlinear (albeit smooth) curve of resistance versus temperature (not good). As a result, circuit and system designers must implement one or more strategies to deploy them effectively. Such techniques include multipoint calibration, employing multiple thermistors with overlapping ranges, lookup tables (often aided by interpolation), or performing correction calculations based on the standard Steinhart-Hart equation (or a simplified regression polynomial), which models their transfer function.

Recognizing both their attractiveness and shortcomings, Texas Instruments (TI) has introduced a family of silicon-based positive-temperature-coefficient (PTC) thermistors—the complement of NTC devices—with what they maintain is 50% higher accuracy. For example, the TMP61 is a highly linear PTC thermistor with 10-kΩ nominal resistance at 25°C, with ±1% maximum nonlinearity from 0 to 70°C and a –40 to +125°C operating range (Fig. 1).

It offers consistent sensitivity across the temperature range with a temperature coefficient of resistance (TCR) of 6400 ppm/°C at 25°C and 0.2% typical TCR tolerance across the operating range (the similar TMP63 has 100-kΩ nominal resistance at 25°C, as does the 47-kΩ TMP64). Compared to NTC devices, the thermistors require little or no linearization circuitry or software, require only single-point calibration, have less resistance-tolerance variation, and offer higher sensitivity at high temperatures.

TI claims that by eliminating the need for additional linearization circuitry or redundant NTC thermistors, these PTC thermistors simplify design, lower system cost. and reduce printed-circuit-board (PCB) layout size by at least 33% when compared to NTC thermistors.

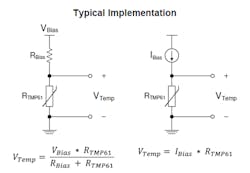

As with all devices, and especially temperature sensors that are often in hostile environments, failure is indeed an option and possibility. Thermistors can be driven by a voltage or current source (Fig. 2), and while there are pros and cons to each drive approach, a short circuit could have system-wide implications. For this reason, the TI devices include a built-in “fail-safe” in the event of short-circuit failures.

Of course, physical sensor size is a factor in temperature sensing, as sensor thermal mass affects both response time and ability to site the sensor close to the point of interest. Among the available packages, the TMP61 is offered in 0.60- × 1.00-mm (0402 footprint compatible), 4.00- × 3.15-mm (TO-92S), and 0.80- × 1.20-mm (SOT-5X3) packages; the TMP63 comes in a 0.60- × 1.00-mm package, and other TMP packages are available. In addition, the 10-kΩ TMP61 and 100-kΩ TPM63 are available in automotive-grade versions. Prices begin at US$0.05 in 1,000-unit quantities.

For test and evaluation, TI offers the TMP6EVM evaluation kit, which is powered via a USB connection or a CR2032 coin-cell battery (Fig. 3). This standalone module includes the company’s TMP116 digital sensor for local temperature reference along with two analog channels. The sensor section of the circuit board can be separated from the main board to emulate a system where the sensor is remotely located from the host controller (a common situation), while the LCD displays real-time streaming of temperature measurements at a 2-Hz update rate.

Full product details, including links to individual datasheets, access to a thermistor-design tool, and a short video, are available here, while details on the TMP6EVM are posted here. There’s also a useful, highly readable tutorial and application white paper “Temperature sensing with thermistors.”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.