Tiny TEC Regulator Module Merges Precision Control Loop and Source/Sink Capability

Thermoelectric coolers (TECs) based on the Peltier effect can be used for general cooling, but more often they’re applied to maintain a precise temperature for subsystems and components. And unlike fans, they can heat as well as cool (the TEC designation is somewhat misleading, as many of these TECs can also provide some heating). Such thermal management that goes beyond just simplistic device cooling is critical where performance is sensitive to temperature shifts. Thus, it requires a high degree of stabilization, more so than absolute accuracy.

For example, the output characteristics (wavelength, power) of laser diodes are closely tied to their temperature. Shifts away from the target operating point can dramatically impact system performance. A closed-loop temperature-control stabilization scheme based on a co-located temperature sensor and a Peltier module for cooling (and heating) is therefore often used to provide the required temperature-control function.

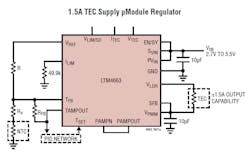

To implement this control loop, Analog Devices announced the LTM4663, a complete 1.5-A sink/source thermoelectric cooler (TEC) regulator in a 3.5- × 4- × 1.3-mm LGA package (Fig. 1). This highly integrated µModule includes a TEC controller, linear power stage, switching regulator, inductor, and nearly all support components; only external input and output capacitors are needed. The module supports independently programmable heating- and cooling-current limits for asymmetric thermal control, and the TEC voltage and current can be monitored in real-time.

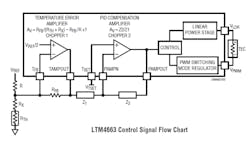

Operating over a 2.7- to 5.5-V input-voltage range and with a default (but adjustable) 2-MHz switching frequency, the LTM4663 also includes two zero-drift, rail-to-rail chopper amplifiers serving as the thermistor input amplifier and the temperature-feedback control loop. These two self-correcting, auto-zeroing amplifiers linearize the thermal sensor input to form an analog temperature feedback control loop. With the zero-drift chopper amplifiers, extremely good long-term temperature stability is maintained via an autonomous temperature-control loop.

Usable in an analog or digital PID control loop, the module includes provision for loop compensation. The two half-bridge power stages, pulse-width-modulation (PWM) switching-mode regulator, and linear power stage control the current flow (in or out) of the connected TEC device (Fig. 2).

In almost every tight, accurate temperature-control scenario, accurate modeling of thermal situation is essential. Among its many performance and application details, the comprehensive LTM4663 datasheet discusses this design aspect beginning with a graphical representation of the many internal and external thermal resistances (Fig. 3; the blue resistances are contained within the µModule regulator while the green resistances are external to it).

The LTM4663 is compatible with both NTC and PTC thermistors as well as resistor temperature detectors (RTDs), and it can deliver 1% accuracy using its 2.5-V internal reference. It’s priced at around $6 in 1000-piece lots.

References

Simple design equations for thermoelectric coolers

Simple Design Equations For Thermoelectric Coolers (Revisited)

CUI Devices, “How to Select a Peltier Module”

CUI Devices, “Reliability Considerations for Peltier Modules”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.