How to Select the Right Motor Driver

Members can download this article in PDF format.

What you'll learn:

- Different types of motors need different types of drivers.

- Requirements for a variety of applications.

Selecting the right motor driver is crucial to achieving the required functionality and performance for a given application. In addition to parameters such as voltage and output current, other key factors depend on not just the type of motor selected, but its intended application.

Type of Motor

Brushed dc motors usually require a reversible driver and often need pulse-width-modulation (PWM), brake, and forward/reverse modes. Ideally, a motor driver for a brushed dc motor should also include a current-limiting function and may need to support a high-speed drive.

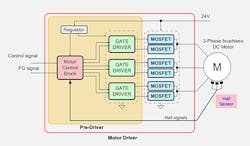

Drivers for three-phase brushless motors, typically used in applications such as paper feeding or fans, often need to be compatible with either a sensorless motor and/or a motor equipped with Hall sensors. Different commutation angles may be involved, and sinusoidal commutation can ensure low noise and vibration (Fig. 1).

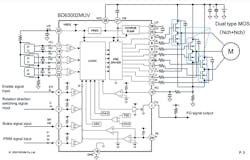

Stepper motors are used when the position and holding torque are more important than rotation or general movement. For stepper motors to run quietly, they often use a mixed-decay function. They usually require two power sources as well as overvoltage and overcurrent protection functions. Various drive methods are employed for stepper motors—often, the method is directly related to how the motor will be used (Fig. 2).

Basic Motor-Driver Parameters

Once the type of motor is established, attention must be given to certain key parameters related to that motor, including:

- Output current

- Application voltage (3.3/5, 12, 24/36, 250, 600 V)

- Rated power dissipation

- Number of outputs

These parameters are extremely important and will significantly narrow down the available choices for the motor driver.

Application Requirements

Motors are a crucial part of printers, vacuum cleaners, cameras, and CNC equipment, not to mention air conditioners, washing machines, and refrigerators. Each of these products requires multiple dc motors to function, with each motor having its own set of requirements. Once the motor and the motor-driver parameters are established, the focus should be shifted to the specific requirements related to the application.

Paper Movers

Paper movers in printers use either a stepper motor or dc brush motor, and, depending on the objective of the printer, the design may require high precision with minimal vibration. The motor type and requirements will vary according to the type of printer (i.e., industrial printer, thermal printer, inkjet printer, or multifunction printer). Some battery-powered thermal printers may need highly efficient control solutions to conserve power, while others, such as inkjet printers, might require highly accurate positioning (Fig. 3).

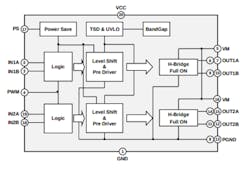

Multifunction printers, for example, often use a three-phase BLDC-motor driver or a stepper-motor driver (either one channel or two channel) for the paper mover. The tray and ink motors normally require a monolithic H-bridge driver. A one- or two-channel H-bridge with two dc-dc buck regulators is the most commonly used design for the system motor driver.

Robot Vacuums

Robot vacuums require separate motors for suction, rolling, rotating drum, and side brushes. While all of the motors are normally three-phase brushless motors, two different general motor-driver categories are used: three-phase BLDC motor drivers and discrete H-bridge dc brush motor drivers. The motor driver that’s used depends on the motor’s purpose within the vacuum (Fig. 4).

Robotic vacuum units are powered by rechargeable batteries, making efficiency a major concern while requiring significant power for the suction motor. In addition, vacuum motors are expected to run quietly, which is another key characteristic that impacts the choice of motor driver (Fig. 5).

Cameras

Essential to the functionality of modern cameras (including SLRs, drone cameras, and security cameras) are motor types such as dc brush motors and stepper motors. Dual H-bridge drivers most often control camera motors. Requirements like high efficiency and compact size are common when camera motors are involved, and drivers that support highly accurate and precise positioning with minimum vibration are important (Fig. 6).

Pan/rotate/tilt functionality in a camera depends on either a low-voltage dc brushed motor with a one-channel H-bridge driver or a stepper motor with a compact high-speed H-bridge motor driver that’s either one- or six-channel. Fully integrated camera drivers are available, as are compact high-speed H-bridge stepper-motor drivers for camera and lens motors (including focus, zoom, and shutter). Auto-focus lens motors most often depend on voice coil motors with open-loop auto-focus drivers.

CNC Motors for Small Machines

A wide variety of small machines depend on CNC (computer numeric control) motors, including laser cutters, vinyl cutters, 3D printers, small milling machines, lathes, and grinders. High-current, compact, and single-channel bipolar stepper-motor drives are the most common choice for CNC products.

Keep in mind that these applications involve multi-axis positioning and, therefore, multiple motors working together. Therefore, the motor drivers chosen must be able to support highly accurate, precise positioning, often requiring micro-stepping precision. In addition, space can be at a premium in these designs.

Motor-Driver Considerations

When choosing a motor driver, the type of motor and basic driver parameters are the correct starting points, but other factors must be taken into account. And considering that each application may require multiple motors, it’s critical to look at the specific purpose of each motor in the system.

ROHM, for instance, has an extensive line of motor drivers engineered for specific applications. All dc motor drivers are designed to provide high reliability with internal protection capabilities and optimized drive waveforms to reduce noise and vibration. In addition, the motor drivers maintain high-efficiency drive control algorithms.

About the Author

George Hariman

Systems Architect, Rohm Semiconductor

George Hariman is currently a Systems Architect at Rohm Semiconductor, where he works to design-in the company’s broad portfolio of analog and power products into end-customer applications. His previous power-management and power-electronics experience includes design of integrated circuits for point-of-load voltage regulators, LED drivers for display, lighting and camera flash products, and other power-management circuits. He holds a Bachelor of Science in Electrical and Computer Engineering from the University of California, San Diego, and a Master of Science in Electrical Engineering from Stanford University.