Merck to Spend $1 Billion to Boost Supply of Chip Materials in U.S.

Merck KGaA of Darmstadt, Germany, which supplies raw materials used in chip fabs, is investing $1 billion in its U.S. operations and partnering with Palantir Technologies to create software that aims to address the supply chain woes in the chip industry.

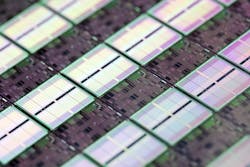

The company—whose North American electronics business is known as EMD Electronics—supplies a wide range of chemicals and other materials used by chip vendors and display panel makers. These range from photoresist, a polymer paired with a photomask to imprint transistors on a silicon wafer, to materials used in many other phases in the chip-making process, such as deposition and etching.

Merck's move comes as the U.S. works to approve the CHIPS for American Act, which would roll out $52 billion in subsidies to lure more chip fabs to the U.S., which would, in turn, hike demand for raw materials.

The company plans to spend $1 billion through 2025 to expand its production capacity for materials and chemicals at sites in Arizona, California, Texas, and Pennsylvania. The funds will also fuel its research and development.

A global shortage of chips and other parts has been devastating auto production for about the last year. One of the bottlenecks in the supply chain is raw materials, ranging from blank silicon wafers, the fundamental building block of all chips, to chemicals and gases used to treat them. In addition, production snags have also hit the global supply of substrates and resins used in packages, raising prices for chip makers.

"The chip shortage needs industry-wide cooperation to resolve the supply chain issues consumers are currently facing," said Kai Beckmann, CEO of Merck's electronics arm, in a statement.

Merck also said it was forming a new venture with Palantir Technologies. The company, called Athinia, aims to create software tools that can collect data on fab operations and coordinate it with data from material and chemical suppliers. Athinia said it will leverage artificial intelligence and big data to aggregate and analyze the data to improve efficiency and give chip firms more transparency into their supply chains.

Merck CTO Laura Matz, who will lead the partnership as Athinia's CEO, said chip firms and materials suppliers have trade secrets and other intellectual property assets they want to keep secret. As a result, they have long been reluctant to share information. Athinia plans to protect the data they communicate to each other by keeping it all anonymous as well as managing it all in a way to prevent contamination, Matz said.

Matz said Athinia is addressing a gap in the electronics supply chain. Previously, there was "no platform for multiple players to share data in a secure way without IP issues," she said, adding that Athinia customers will maintain complete control of their data.

Merck said Athinia would also leverage AI to assist chip firms in improving quality and reducing the time it takes to ramp up production lines. The software, Matz said, could be used to compare a chip's performance against data on the materials and chemicals used to manufacture it. Athinia said suppliers could then use the feedback to improve their materials, while chip firms could use the insights to increase chip quality or yields.

Manufacturing chips is one of the most complex processes in the world, and even slight variations in the compounds, chemicals, gases, and other raw materials that go into chips can impact their quality.

"Quality improvement rates will be rather incremental, as the big levers are already known," Matz told Electronic Design. "However, even these small sub-percentage improvements are very important."

Athinia will be housed within Merck's EMD Digital subsidiary and remain separate from its electronics unit.

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.