Piezo Fibers Transform Fabric into Sensitive Microphone

What you’ll learn

- How piezoelectric fibers can be used for acoustic sensing and audio output.

- The test arrangements employed to assess performance from different perspectives.

- The results of some of the tests along with links to more detailed information.

There’s lots of interest in using textiles and fabric as transducers, whether for energy harvesting or as biosensors, and with good reason: Fabric is unobtrusive, ubiquitous, and part of daily life. In fact, there’s so much activity that the IPC has developed an array of defining and relevant standards.

Now, a team at MIT working with collaborators at Rhode Island School of Design (RISD) has developed an “acoustic fabric” that works like a microphone, converting sound first into mechanical vibrations, then into electrical signals (as well as the reverse function).

The fabric operates as a sensitive audible microphone while retaining the traditional qualities of fabrics, such as machine washability and draping. It’s composed of piezoelectric textile yarns woven into the weft of a cotton warp to transform extremely small pressure waves at audible frequencies into lower-order mechanical vibration modes.

The highly sensitive piezoelectric fiber is produced by a sophisticated process to produce a thermally drawn composite that conforms to the fabric as it converts mechanical vibrations into electrical signals. Key to the fiber sensitivity is an elastomeric cladding that concentrates the mechanical stress in a piezocomposite layer with a high piezoelectric charge coefficient of approximately 46 picocoulombs per newton (pC/N).

The result is a fabric that captures sounds ranging from a whisper to heavy road traffic, and it can even determine the precise direction of sudden sounds like hand claps. However, its uses are highly “local” as well: When woven into a shirt’s lining, the fabric can detect a wearer’s subtle heartbeat features. The fibers can even be directed to a generate sound, such as a recording of spoken words, which another fabric can detect.

A Fabric “Ear”

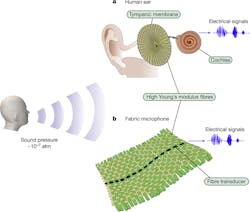

Inspired by the human auditory system, the team sought to create a fabric “ear” that would be soft, durable, comfortable, and able to detect sound (Fig. 1). Their research led to two important discoveries:

- Such a fabric would have to incorporate stiff, high-modulus fibers to effectively convert sound waves into vibrations.

- They would have to design a fiber that could bend with the fabric while also producing an electrical output.

1. Design and principles of fabric microphones: (a) The tympanic membrane is a four-layer construct consisting of circumferentially and radially oriented high-modulus collagen fibers, which are key for sound conduction. The tympanic membrane motion is ultimately transmitted to the cochlea through the ossicular chain, wherein short cilia fibers convert pressure waves into electrical signals (ionic), which are picked up by the nervous system. (b) In the acoustic fabric, high-modulus Twaron yarns and cotton yarns are oriented at right angles, mimicking the construction of the tympanic membrane. This results in a fabric capable of operating as a sensitive microphone that detects weak sound signals (for example, human speech) as low as 10⁻⁷ atm.

They developed a layered block of materials called a preform, made from a piezoelectric layer as well as ingredients to enhance the material’s vibrations in response to sound waves. The resulting preform, about the size of a thick marker, was then heated and pulled like taffy into thin, 40-meter-long fibers.

The details of the material, development, and fabrication of piezoelectric yarns and associated fabric are involved. However, the Electronic Design audience is likely just as interested in the test arrangement and results.

Testing Takeaways

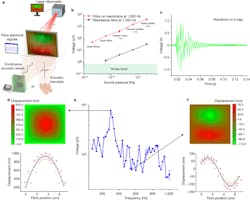

The researchers first tested the fiber’s sensitivity to sound by attaching it to a suspended sheet of Mylar and used a laser to measure the nano-vibrations of the sheet—and by extension, the fiber—in response to sound played through a nearby speaker (Fig. 2). The fiber vibrated and generated an electric current proportional to the sound over a wide range of intensities (Fig. 3).

2. Acoustic fibre-on-membrane characterization: (a) The continuous sound waves are generated from a speaker and the impulse is generated from a clap. (b) The output voltage versus sound pressure of the fiber-on-Mylar system at 1,000 Hz. (c) The output voltage of the fiber-on-Mylar system in response to a clap, after it has been amplified 68X. (d) Measured vibrational (1, 1) modes together with z-displacement (perpendicular to membrane surface) of the membrane (top) and fiber (bottom) at a resonance frequency of 300 Hz. (e) Measured frequency response of the sample from 80 to 1,000 Hz. (f) Measured vibrational (1, 2) modes together with z displacement (perpendicular to membrane surface) of the membrane (top) and fiber (bottom) at an anti-resonance frequency of 550 Hz.

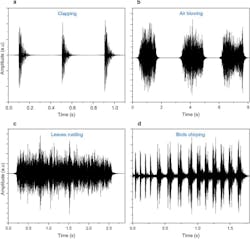

3. Audible sound detection using the fiber-on-membrane system, with time-dependent waveforms of a clap (a), air blowing (b), leaves rustling (c), and birds chirping (d).

They also went from a formal test arrangement to application scenarios:

- They wove the fiber with conventional yarns using a standard loom to produce panels of drapable, machine-washable fabric with the feel of a lightweight jacket—lighter than denim, but heavier than a dress shirt. They then sewed one panel to the back of a shirt and tested the fabric’s sensitivity to directional sound by clapping their hands while standing at various angles to the shirt. “The fabric was able to detect the angle of the sound to within one degree at a distance of three meters away,” noted team member Grace Noel.

- They stitched a single fiber to a shirt’s inner lining, just over the chest region, and found it accurately detected the heartbeat of a healthy volunteer, along with subtle variations in the heart’s S1 and S2, or “lub-dub,” features.

- Finally, the researchers reversed the fiber’s function from sound detector to sound source, operating as a loudspeaker. They fed a recording of spoken words to the fiber and the fiber converted the electrical signals to audible vibrations, which a second fiber was able to detect.

Of course, a fabric that’s not washable is of little practical use in consumer situations. For this reason, they also ran the fabric through 10 wash cycles and assessed changes in capacitance—a key metric for piezoelectric activity and consistency—as well as voltage output versus frequency (Fig. 4).

4. The washability of the acoustic fabric: (a) Snapshot photographs of the acoustic fabric being washed in a washing machine at room temperature. (b) The constant capacitance with washing cycles (left), and the voltage versus frequency of the acoustic fabric before it’s washed and after it’s washed for 10 cycles (right).

Their analyses goes well beyond devising, fabricating, and evaluating fibers and woven textiles. It also includes detailed theoretical stress/strain analyses from various material-science perspectives.

The work is detailed in their paper “Single fibre enables acoustic fabrics via nanometre-scale vibrations” (with 18 authors) published in Nature. While the paper itself is behind a paywall, the first page of the paper and its many figures with their extensive captions are available here, and they tell much of the story as well. The paywalled site does include open links to Extended Data Figures and Tables and a lengthy Supplementary Information file that also includes videos.

This research was supported in part by the U.S. Army Research Office through the Institute for Soldier Nanotechnologies, the National Science Foundation, and Sea Grant NOAA (a national network of 34 university-based programs and the National Sea Grant Library).

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.