Papertronics: Biodegradable R-C-FET Amplifier Fabbed on Paper Substrate

What you’ll learn:

- How a paper substrate and biodegradable circuitry can be used for basic circuits.

- How the researchers fabricated and connected active and passive devices literally “on paper.”

- Details of their first, basic amplifier circuit.

The push to make electronic products more environmentally friendly has several perspectives. One is to look at what can be done to reduce to impact of single-use devices and sensors, which are often used to evaluate human health and monitor environmental conditions, and for other specialty situations.

To address this concern, a team based at the Binghamton University (State University of New York) devised a technique to fabricate and connect passive and active electronic components that are fully paper-based and integrated on paper-based printed circuit boards, thus providing a realistic and practical solution for green electronic platforms.

Dubbed “papertronics,” their prototype circuit board is made of a sheet of paper with fully integrated electrical components, and it can be left to degrade harmlessly. Applications include point-of-care diagnostics, logistics tracking, and environmental and food testing.

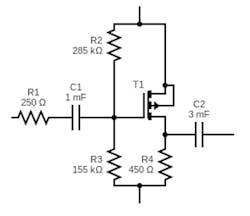

The team designed a basic paper-based amplifier-type circuit that incorporated resistors, supercapacitors, and a field-effect transistor (Fig. 1). (Yes, it’s simple, but you have to start somewhere—after all, Jack Kilby’s first IC was a basic analog amplifier.)

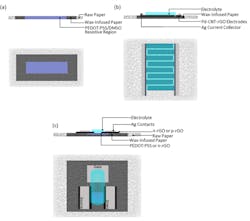

Using a 3D printer, they began by using wax to print channels onto a sheet of paper in a simple pattern, somewhat analogous to the use of resist in conventional semiconductor manufacturing (Fig. 2).

After melting the wax so that it soaked into the paper, the team printed semi-conductive and conductive inks, which soaked into the areas not blocked by wax. The researchers then screen-printed additional conductive metal components and “cast” a gel-based electrolyte onto the sheet.

Each component type had its own layered structure (Fig. 3).

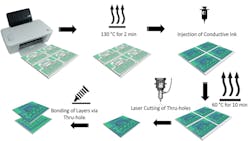

Tests confirmed that the resistor, capacitor, and transistor designs performed as modeled. The final circuit was very flexible and thin, just like paper, even after adding the components. They also anticipated how their scheme could be scaled up somewhat via a small-scale batch-processing scenario (Fig. 4).

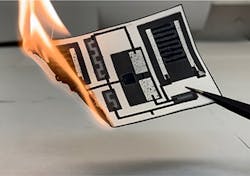

To further demonstrate the quick degradability of the circuit, they showed that the entire unit soon burns to ash after being lit on fire (Fig. 5).

Seokheun Choi, Professor in the Department of Electrical & Computer Engineering and project mentor, noted that “papertronics will be suitable for disposable wireless sensor networks (WSNs) through the Internet of Things, named the Internet of Disposable Things (IoDT). The novelty in the IoDT is that its WSNs can be constructed with small, compact, disposable, functional, but inexpensive packages that can connect until the job is done and then be readily thrown away.”

Funding for the work came from the National Science Foundation. The project, including specifics on the materials and fluids used, is detailed in their paper “Integrated Papertronic Techniques: Highly Customizable Resistor, Supercapacitor, and Transistor Circuitry on a Single Sheet of Paper” published in American Chemical Society’s Applied Materials & Interfaces. Their brief Supporting Information file adds more graphs and tables showing the electrical characteristics of the individual resistors, p- and n-type FETs, and various interdigitated millifarad-range capacitors they fabricated.

References

AZO Materials, “Papertronics: Disposable Electronics on a Single Sheet of Paper.”

Binghamton University, “A passion for papertronics: Graduate’s research published in prestigious journals.”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.