Precision Current Monitor, Hot-Swap/Ideal-Diode Controller Meet Automotive Standards

The “electrification” of numerous functions within automobiles and related vehicles continues, and that trend applies to all vehicle types—those with internal combustion engines (ICE), hybrid electric vehicles (HEV), or pure electric-only EVs. Consequently, and perhaps with some irony, this increased complexity is also driving the need for relatively simple, single-function, tightly focused analog/power ICs that meet the unique and expanding needs of the added electrical functions.

An additional benefit comes via the “law of unintended consequences,” as designers of non-automotive systems can also use these high-reliability devices. After all, their functionality is fairly universal. Two recent introductions typify the continuing rollout of such components.

Diodes Inc.’s New Current-Shunt Monitors

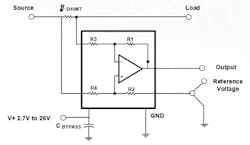

From Diodes Inc., the ZXCT21xQ series high-precision current-shunt monitors measure a low voltage drop (10 mV nominal) across a small-value shunt resistor with minimal error (Fig. 1). These single-stage instrumentation amplifiers are designed to accurately measure very small sense voltages across a wide range of common-mode voltages.

Applications include current sensing of power rail/load currents in BLDC motor control, high-power dc-dc converters, real-time reporting of state-of-health in critical equipment, and battery-charging equipment.

Qualified to automotive AEC-Q100 Grade 1, these monitors enable measurement of higher-current values with high accuracy, at common-mode voltages from −0.3 to 26 V. Their low offset voltage (±30 μV) combined with a zero-drift core (typical ±100 nV/°C) enables current sensing across the shunt with maximum full-scale voltage drops as low as 10 mV.

Thus, lower-value sense resistors can be used to monitor those large currents, which reduces the unavoidable power loss caused by the resistor-based measurement arrangement and consequential IR drop.

These devices can be utilized for unidirectional current measurement, such as power flowing to a load. They can also be configured for bidirectional current sensing, needed for a battery-management system (BMS) where current is measured as the battery is being both charged or discharged. Versions with different part numbers are available with fixed gains of 50, 75, 100, 500, and 1000 V/V.

The ZXCT21xQ operates from a single 2.7- to 26-V power supply with a maximum of 100 μA of supply current from −40 to +125°C, and comes in a SOT363 package. The 14-page datasheet provides detailed specifications as well as graphs, and application details.

ST’s Hot-Swap and Ideal-Diode Controller

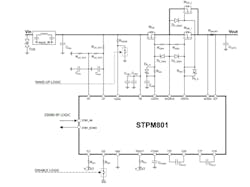

Supporting another aspect of automotive electrical subsystems, STMicroelectronics claims its STPM801 is the first automotive-qualified, integrated hot-swap and ideal-diode controller classified for functional-safety applications. In addition to the integrated hot-swap function, it includes soft-start and ORing protections (Fig. 2).

The IC protects loads from high-voltage transients, limiting and regulating the output during an overvoltage event, such as load dump, by controlling the voltage drop across an external N-channel MOSFET. Application areas include zonal/body ECUs, advanced driver-assistance system (ADAS) electronic control units (ECUs), high-performance computing ECUs, infotainment ECUs, redundant power-delivery systems, and dual-battery systems.

It offers a set of features to support applications that need to fulfill functional-safety requirements as defined by Automotive Safety Integrity Level (ASIL) A-B-C-D depending on the application’s Technical Safety Requirements (TSR).

The IC’s ideal-diode controller drives an external MOSFET replacing a Schottky diode conventionally used for reverse-input protection and output-voltage holdup. The ideal-diode controller circuit also provides power ORing to switch between a main and backup battery to ensure uninterrupted supply to safety-critical equipment such as autonomous driving and ADAS. The STPM801 also monitors the input supply to protect in case of overvoltage and undervoltage conditions.

The reduced voltage drop across the external MOSFET reduces power dissipation during normal operation, compared to the forward voltage of the Schottky diode. When a reverse-voltage event occurs, in case of faults like power source failure, brownout, or input short-circuit, turning off the MOSFET blocks the associated reverse-current transients.

The integrated hot-swap controller also drives a second external N-channel MOSFET to protect loads during hot-swap events. A soft-start function controls the turn-on transient of this second MOSFET by charging a capacitor of known value connected to its gate at constant current to avoid high inrush currents. The overvoltage and undervoltage pins cut off the output voltage whenever the input voltage is not within specified thresholds.

The STPM801 also includes protection features and monitoring suitable for applications that meet functional-safety requirements for systems up to ASIL D according to ISO 26262. The features are packaged within a 5- × 5-mm VFQFN-32 footprint, saving PCB space and minimizing demand for external components.

The device operates from a 4- to 65-V supply voltage, with just 25-µA quiescent current. As a result, the STPM801 withstands automotive electrical hazards and minimizes battery drain when the vehicle is turned off. The STPM801 is in mass production now and available starting at $3.00 each (1,000-piece orders). It’s supported by a comprehensive 38-page datasheet.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.