This file type includes high-resolution graphics and schematics when applicable.

Back in 2011, Jeff Hamilton contacted Bob Pease, asking for Bob’s experience with the classic 555 timer IC. Jeff wrote Pease, “As part of celebrating a part with 40 years in the market, I thought you might have a story about the 555 that you would be willing to share. Any story, from your first experience with the device to perhaps a clever application or entertaining abuse of the device would be appreciated.”

Pease replied in his characteristically straightforward way. He noted:

“Hi, Jeff H., I have almost never used a 555. Maybe never? I use op-amps, LM324's, LM311's, LF356's. I use 74HC04's and 74C14's but not 555's. I've used ECL fast logic, and discrete transistors. But the 555 just does not do anything precise, or even semi-precise, that I need done. So that's one thing I can "share" - my favorite circuit to use a 555, is: a blank piece of paper. Never touch the things. Go ahead and print that. / rap”

I agree with Pease, and have always regarded the 555 timer as more of a hobbyist IC. By that I mean it can get you in trouble in any volume application where repeatability and consistent performance is critical. Pease’s comment about the 555 not being precise is true. Not only is accuracy limited by the components you hang around it, the part-to-part variance is pretty bad.

Furthermore, maybe you designed in the knock-off CMOS version, and the purchasing agent decided to be a hero and substitute some third-world-sourced, original bipolar part. After all, both parts have 555 in the part number, so they both must work, right? Purchasing agents should know that a different company’s 555 is a different die, and sometimes a different IC process, and it will need to be qualified like any other part change.

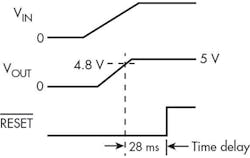

The first time I was burned by a 555 was back in the 1980s, when I tried to use one as a reset generator in a military communication system (Fig. 1). When I applied power, there was nothing consistent about the one-shot pulse out of the 555. Fortunately, Electromagnetic Systems Laboratories (now TRW) had some “greybeard” analog guys that could school me. They explained no IC with latches and such could be trusted to behave consistently on power-up. It’s a digital chip at heart. Things would go wrong depending on how fast or slow the power rail came up. There was always the fun of power spikes caused by relays or switches that apply the power. There was also the condition of rapid power cycling that would make the performance of the IC unpredictable.

When I asked them what was I to do, they all replied, “You have to make a reset circuit out of a few discrete transistors and capacitors and resistors, and you have to intimately understand how it works under all those conditions.” Thankfully, since those early days, companies like Maxim have developed entire portfolios of reset ICs that do behave very predictably and can save space and cost over a discrete circuit (Fig. 2). Please pay Maxim whatever they ask rather than think you can cheap-out with a 555 timer.

Other problems I have had with 555s involve their power-supply sensitivity. Now when Hans Camenzind designed this famous part, he did make it insensitive to the power supply in the first order. But the frequency of operation or pulse-width time will change a little with power amplitude. Other part deficiencies are input transients causing problems, or temperature sensitivity that changes the frequency or pulse widths.

Then there are the problems we create with the components in our 555 circuits. If you use high-value resistors, you start to get problems with leakage. When it’s in production and goes to a humid location, the frequency changes with the weather. Low-value resistors use a lot of power. If you use low-value capacitors, you get problems with stray capacitance on the board. It becomes a proximity sensor that changes frequency when your hand gets near it.

If you use large-value polarized capacitors, well, they not only have high leakage, but they are also very poor in reliability. Ceramic capacitors are microphonic; they will change the circuit frequency when you tap on them. The acoustic nature works both ways—the ceramics will emit sound if the circuit frequency is in the audio range.

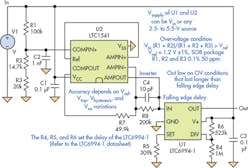

Thankfully, just like Maxim solved your power-on reset problems, Linear Technology has solved your 555 timing problems with its line of TimerBlox chips. Indeed, LTC says you can use TimerBlox for doing power-on reset as well (Fig. 3). Leave it to analog companies to understand the transistor-level operation of their parts, as opposed to some IBIS approximation of digital behavior.

And blissfully, the TimerBlox circuits don’t require any capacitors, so all of the headaches with leakage or stray capacitance or microphonics or reliability go away. My pal Tim Regan (Fig. 4) was application manager at Linear Tech when the TimerBlox came out. Tim developed an Excel spreadsheet to help you use TimerBlox chips. Tim is retired now, but when I asked about TimerBlox, he noted:

“I think Pease would have liked the TimerBlox for their simplicity and no need for big capacitors to do really long timing functions. What he wouldn't like is that they don't need any of his requisite sprinkle of diodes and small capacitors around the circuit addressing the 4th- or 5th-order effects that only he would always consider. He also wouldn't be impressed with the 2% accuracy (although better than a 555), and limited 1-MHz frequency range. He was a VCO [voltage-controlled oscillator] purist at heart.

“Doing the TimerBlox datasheet application circuits was both easy and challenging. Easy because the parts are so simple to set up and they do what they are supposed to do. Kind of like a logic gate, I would tell folks. The apps section was challenging because when you consider timing requirements in just about any system, the specific applications are innumerable. There are always conditions where there is a specific time that something must happen, or not happen. When a timing situation befalls you, it is nice to have a simple device available to come in and make things happen when they should.

“As for my spreadsheet design tool, my successors have made it much slicker than I ever did. Check out the landing page for any of the TimerBlox. Try the LTC6993 one-shot. They have the design tool running online now. It is definitely the way to go these days. I always had an issue with the Linear FAEs [field applications engineers] who all used Macs while I only knew PC's. They couldn't run my spreadsheet which used elements that Microsoft and/or Apple never got around to making work on both platforms. Now that it works online, anyone can use it to knock out TimerBlox circuits in just seconds.

“I just now remembered that Pease showed me a temperature-to-frequency converter he was working on [when I was at National Semiconductor]. It had a fancy PTAT [proportional to absolute temperature] circuit and all. I suggested that he consider doing the opposite, frequency-to-temperature. Just put in a square wave, crank up the frequency, and watch the sucker get hotter than hell. He was really amused with the complete uselessness of such a device. I enjoyed accommodating his sense of humor!”

Now this is not to say you should never use a 555. Life is analog and there are places where a cheap 555 might do the trick for a little one-off test box, or maybe you don’t need anything precise, stable, robust, or repeatable. As that book notes, “Every Hun has value — even if only to serve as a bad example.”

One real value of the 555 is teaching the principles of electronics. For that we have the fantastic 555 kit built out of discrete transistors (Fig. 5). This kit will let you probe all of the internal nodes to understand how the chip really works. Note this is based on the bipolar transistor 555, not the CMOS version from Intersil.

When I expressed these frustrations I had with the 555 to Pease, he remarked, “I think you and I did a good job to throw a wet blanket over the poor old '555. Should I mail a copy to Uncle Hans Camenzind? Naw, I'll save 44 cents and let someone else do it. Thanks for cutting me in on the fun. / rap”

Thing is, both Bob and I do respect Hans Camenzind, and his early creation of a system-on-a-chip that has sold more than any other IC. The billion parts sold every year must be good enough for a lot of engineers and more power to them. One thing I loved about Hans is when he told me how he had to fight marketing people who saw no use for the chip.

This jibes perfectly with the observations of Clayton Christensen, who noted in his famous book, Innovator’s Dilemma, how marketing departments rarely saw new markets, they just wanted to sell something cheaper to the existing market they were serving. He noted it was the technical people that would invent something new, for a new market. Hans sure did that, and I will always respect him for that, even if Pease didn’t use his part.

About the Author

Paul Rako

Creative Director

Paul Rako is a creative director for Rako Studios. After attending GMI (now Kettering University) and the University of Michigan, he worked as an auto engineer in Detroit. He moved to Silicon Valley to start an engineering consulting company. After his share of startups and contract work, he became an apps engineer at National Semiconductor and a marketing maven at Analog Devices and Atmel. He also had a five-year stint at EDN magazine on the analog beat. His interests include politics, philosophy, motorcycles, and making music and videos. He has six Harley Sportsters, a studio full of musical instruments, a complete laboratory, and a video set at Tranquility Base, his home office in Sun City Center Florida.