IC Trio Makes Non-Magnet Inductive Sensing Easier and More Accurate

What you'll learn:

- Where non-magnetic inductive sensing is an attractive approach.

- The challenges of configuring these sensors.

- How a new trio of sensor-interface ICs and coil-optimizer tool simplify the challenge.

It may be news to keyboard warriors who spend their time figuring out how to work AI into everything and anything, but out in the real world, systems doing useful work often require sensing of physical variables such as position, velocity, or temperature. Further, being able to do so with greater accuracy and consistency, and with less cost, are markers of a good design.

Addressing this issue, Renesas Electronics introduced a trio of magnet-free inductive position-sensor (IPS) ICs. They can be fully customized for various coil designs for a wide range of industrial applications, such as robotics, medical and healthcare, smart buildings, home appliances and motor commutation (Fig. 1).

Built for high resolution, precision, and robust performance, the RAA2P3200, RAA2P3226, and RAA2P4200 sensor ICs offer cost-effective alternatives to traditional magnetic and optical encoders, which can be bulky, expensive, and require maintenance. Renesas also launched a web-based design tool that allows customers to easily create custom sensing elements to meet their specific system needs.

How Do These Sensors Operate?

Leveraging non-contact coil sensor technology, these devices use a simple metallic target and dual-coil or single-coil configurations to detect absolute rotary, linear, or arc positions. They’re designed to maintain stable operation despite elevated temperatures (−40 to 125°C), particulate matter, moisture, mechanical vibration, and electromagnetic interference.

Moreover, unlike magnetic- or optical encoder-based sensors, they’re immune to stray magnetic fields and require no maintenance. If you’re not familiar with non-magnet coil-based sensing, see “Principle of Magnet-Free Inductive Position Sensing” below.

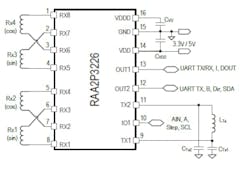

All three products offer high precision in detecting target positions, with accuracy better than 0.1% of the full-scale electrical range and operating from a single 3.0- to 5.0-V supply. The internal complexity of these 16-lead TSSOP package devices (4.4 × 5.0 mm) is transparent to the user, as seen in the internal block diagram (Fig. 2).

The three similar yet distinct devices have common features as well as unique ones. Their durability and low upkeep make them a reliable and cost-effective sensing solution for motor drives, actuators, valves, service robots, and infrastructure applications, where reliability and long-term performance are critical. Standard features include automatic calibration and linearization to simplify integration and improve system-level performance.

Breaking Down the Three ICs

The RAA2P3200 is optimized for high-speed motor commutation with low-latency for motor commutation, E-bikes and industrial robots/cobots:

- Output interfaces: SPI, UART, ABI, UVW, or Step-Dir

- Automatic gain control (AGC) to compensate for air-gap variations

- 16-point linearization feature to improve accuracy

- Rotary on-axis and off-axis, arc, and linear implementations possible

- Operate at 600K RPM (electrical) with propagation delays under 100 ns

The advanced RAA2P3226 provides the high-precision performance required for robotic applications:

- Supports dual-coil sensing up to 19-bit resolution and 0.01-degree absolute accuracy (integrated Vernier)

- Output interfaces: UART, ABI, Step-Dir, I²C

- AGC to compensate for air-gap variations

- 16-point linearization feature to improve their accuracy

- True-power-on position information at startup

- Rotary on-axis and off-axis, arc, and linear implementations possible

- Operate at 600K RPM (electrical) with propagation delays under 100 ns

The RAA2P4200 targets low-speed applications such as medical devices and power tools:

- Output interfaces: Analog, PWM, I²C

- AGC to compensate for air-gap variations

- 16-point linearization feature to improve accuracy

- Rotary on-axis and off-axis, arc, and linear implementations possible

- Overvoltage, reverse polarity, and short-circuit protection

Completing the Design

Designing with inductive position sensors typically involves integrating a printed circuit board, an IC with passive components, and a metal target mounted to the moving part. The most complex part is the external sensing element, such as the transmitter and receiver coils, which must be precisely configured to realize accuracy and customized to the system’s mechanical and environmental requirements.

For this reason, Renesas offers a web-based Inductive Position Sensor Coil Optimizer tool that addresses the challenge by automating coil layout, simulation, and tuning, thus significantly reducing the learning curve for developers. With this tool, engineers can also obtain accurate performance estimates and overcome manufacturing constraints by optimizing the coil layout (Fig. 3).

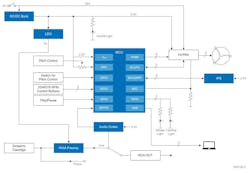

Each sensor-interface IC is supported by a highly detailed, comprehensive datasheet (50-, 43-, and 35-page datasheets, respectively). For those who need to get “hands-on” quickly, Renesas has combined the RAA2P3226 with other compatible devices to develop two winning combinations. They’re technically vetted system architectures from mutually compatible devices: a Mini BLDC Servo and a Turntable System (Fig. 4). Of course, there’s some irony in using this leading-edge sensor interface with that “ancient” music-playback system, one which is currently undergoing somewhat of a trend revival.

Principle of Magnet-Free Inductive Position Sensing

There are many ways to sense position through use of optical, magnetic, and resistance techniques. A magnet-free inductive-position sensor works by detecting the position of a simple metallic target using the principle of eddy currents. It utilizes a set of coils (one transmitter, two receivers) to generate a changing magnetic field.

When the metallic target moves, eddy currents are induced in it, which in turn generate their own magnetic field that interferes with the sensor's receiver coils. The sensor detects this change in magnetic field to determine the target's position. The output is often a ratio of the sinusoidal signals from the two receiver coils. The ratiometric approach is used to minimize the influence of variations in the air gap between the coils and the target and cancels many internal error sources, just like a Wheatstone bridge.

There are many advantages to this non-magnet approach:

- The elimination of the need for a magnet, of course, and immunity to stray magnetic fields.

- High accuracy and resolution, even under harsh environmental conditions.

- Contactless operation and immunity to environmental factors like temperature, moisture, and vibration contribute to high reliability and low maintenance.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.