Magnetic Current Sensor Handles Up to 50 A from DC to 5 MHz

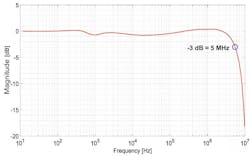

Featuring DC to 5-MHz bandwidth, Allegro MicroSystems' galvanically isolated, high-accuracy magnetic current-sensor IC with zero current reference (ACS37030), and overcurrent fault with internal pull up (ACS37032) option, protect wide-bandgap GaN devices by sensing current over the industry’s widest frequency range for automotive, industrial, and consumer applications. Featuring a narrow or widebody design, the device is 5X faster and 40% to 70% smaller than existing solutions.

The ACS37030 uses two signal paths: a Hall-effect element path to capture DC and low frequencies, and an inductive coil path to capture high frequencies. The two paths are combined internally to allow for sensing of a wide frequency band with a single device.

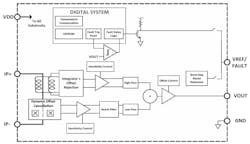

Despite the internal complexity, the component features a single analog output proportional to the current across the entire bandwidth. No customer configuration is required to operate this device, as shown in a typical application circuit (Fig. 1).

The internal construction (Fig. 2) provides high isolation by magnetically coupling the field generated by current flow in the conductor to the fully monolithic Hall and coil IC. The current is sensed differentially by two Hall plates and two coils that subtract out interfering common-mode magnetic fields.

The IC has no physical connection to the integrated current conductor and delivers a 3,500 V RMS (LZ) and 4,242 V RMS (MY) isolation voltage between the primary signal leads. These high ratings provide a basic working voltage of 905 V RMS (LZ) and 1,000 V RMS (MY) isolation voltage between the primary and secondary signal leads of the package.

The ACS37030 fills a critical performance gap at the intersection of traditional current transformers, shunt resistors, and traditional magnetic current sensors. Current transformers are incapable of accurately measuring low-frequency DC currents due to their operating principles. This can necessitate an additional sensor (a shunt or magnetic current sensor), which requires the system controller to make multiple measurements from different sources for different purposes.

The new sensor eliminates the need for the designer or system engineer to design a current transformer or other circuits to measure low-frequency currents, which otherwise would require extra time to define the target phase shift at a specific frequency. In addition, because of their inherently larger size, current transformers are, in many cases, the tallest component in the system— and they often determine the overall size of the power-supply module.

System designers benefit from the significantly smaller size of the ACS37030. For example, server designers can use the space savings to increase data-center power-supply density (measured in kW/in3). Battery electric vehicle (BEV) designers can reduce the weight of EV power-conversion systems to improve range.

Shunts and traditional magnetic current sensors have their own set of shortcomings. They are too slow to protect wide-bandgap devices. Moreover, shunts require isolation circuitry to prevent common-mode voltages that could interfere with or damage sensitive measurement instruments. That increases design size, complexity, and cost. The single-chip ACS37030 integrates isolation circuitry and measures both high and low bandwidth.

Performance advantages:

- Highest bandwidth: DC to 5 MHz with a 40-ns response time (Fig. 3).

- Smallest widebody package (6-lead custom SOIC surface mount): Power supplies for AI data-center servers are exceptionally space constrained due to increasing power-density requirements and fixed server-rack sizes.

- Noise (50-mA RMS input-referred noise): 2X lower noise compared to competing sensors and 4X lower noise than a typical magnetic current sensor. Low noise is critical in high-speed sensing by accurately detecting and reporting GaN overcurrent events without “tripping on the noise” and causing false overcurrent events. Low noise also enables high efficiency at light loads; the sensor still has an accurate output when currents are much lower, and any control loop can respond appropriately.

Unlike current transformers, shunt resistors, and traditional magnetic current sensors, the ACS37030 current sensor, as mentioned, is 40%-70% smaller and achieves a 40-ns response time that enables it to detect and report an overcurrent event well before it damages the GaN device. The device senses both AC and DC, enabling it to measure and report an overcurrent. In addition, the sensor can operate as a low-speed control loop for applications like motor drives and DC-DC output voltage regulation by detecting reduced current.

The ACS37030/32 is provided in two six-lead custom SOIC surface-mount packages; these packages are low resistance, <1 mΩ with fuse-lead current conductors. The LZ package has a resistance of 0.6 mΩ with a creepage/clearance of 4.1 mm, while the MY package has a resistance of 0.9 mΩ with a creepage/clearance of 8.5 mm. The leadframe is plated with 100% matte tin, which is compatible with standard lead-free, PCB assembly processes. Internally, the device is Pb-free as well.

Bare evaluation boards are available, offering a method for evaluating Allegro current sensors in a lab environment. Figure 4 shows the LC/LZ/OL Package Bare Evaluation Board. The board (ACSEVB-LC8-LZ6, TED-0004110) is intended for use with any LC, OL, or LZ package (custom 6- or 8-pin SOIC) Allegro Hall-based current sensor.

Devices are normally stocked at distributors with pricing around $6. We've provided a datasheet here for your convenience, but strongly suggest picking up the latest revision datasheet and design resources from Allegro before starting design.

A quick review of the devices' salient characteristics is contained in the following video:

Features overview of the Allegro ACS38030 DC to 5-MHz current sensor

To keep up with Electronic Design’s latest automotive-related articles, please subscribe to our Automotive Electronics bi-weekly newsletter.

About the Author

Andy Turudic

Technology Editor, Electronic Design

Andy Turudic is a Technology Editor for Electronic Design Magazine, primarily covering Analog and Mixed-Signal circuits and devices and also is Editor of ED's bi-weekly Automotive Electronics newsletter.

He holds a Bachelor's in EE from the University of Windsor (Ontario Canada) and has been involved in electronics, semiconductors, and gearhead stuff, for a bit over a half century. Andy also enjoys teaching his engineerlings at Portland Community College as a part-time professor in their EET program.

"AndyT" brings his multidisciplinary engineering experience from companies that include National Semiconductor (now Texas Instruments), Altera (Intel), Agere, Zarlink, TriQuint,(now Qorvo), SW Bell (managing a research team at Bellcore, Bell Labs and Rockwell Science Center), Bell-Northern Research, and Northern Telecom.

After hours, when he's not working on the latest invention to add to his portfolio of 16 issued US patents, or on his DARPA Challenge drone entry, he's lending advice and experience to the electric vehicle conversion community from his mountain lair in the Pacific Northwet[sic].

AndyT's engineering blog, "Nonlinearities," publishes the 1st and 3rd Tuesday of each month. Andy's OpEd may appear at other times, with fair warning given by the Vu meter pic.