Auxetic 3D-Printed Pressure Sensors Offer Capacitive, Resistive Modes

What you'll learn:

- Why auxetic materials offer some unique advantages in sensor fabrication.

- How additive manufacturing was used with autextic materials to create unique pressure and force sensors.

- The structure and performance of the capacitive- and resistive-sensing devices that were developed based on these materials and fabrication techniques.

Advances in metamaterials and materials processing via additive manufacturing (3D printing) are being used individually and jointly to develop new components including sensors. An interesting example comes from the Seoul National University of Science and Technology (SEOULTECH). Researchers are seeking to improve the sensing range and sensitivity of tactile sensors that convert external stimuli, such as pressure and force, into electrical signals.

Their efforts began with auxetic mechanical metamaterials (AMMs) — meaning they have a negative Poisson’s ratio— that enable inward contraction and localized strain concentration upon compression. These counterintuitive behaviors make them promising options for designing sensors and actuators with favorable properties.

What's an Auxetic Material?

An auxetic material or structure has a negative Poisson's ratio, meaning it gets thicker when stretched and thinner when compressed, which is the opposite of most common materials. This unusual behavior, which stems from a specific internal micro- or macro-structure, results in properties such as increased impact resistance, higher density under stress, and improved damping, making them useful in applications from running shoes to biomedical devices to protective armor. Auxetic materials are present in a wide variety of industrial and even consumer products.

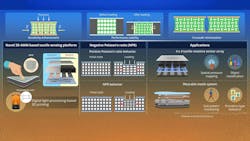

However, existing AMM technology has fabrication and integration challenges. To overcome this, the team devised two sensors based on a cubic lattice with spherical voids that they fabricated using 3D printing and digital light processing: an AMM-based 4×4 tactile array for spatial pressure mapping and object classification, as well as a wearable insole-system sensing platform for monitoring (Fig. 1).

Applying 3D-Printed Auxetic Metamaterials

Their tactile-sensing platform uses 3D-printed auxetic metamaterials in both capacitive- and piezoresistive-sensing modes. While the sensor responds to pressure via electrode spacing and dielectric distribution modulation in the first mode, the latter mode leverages a conformally coated network of carbon nanotubes (CNTs) that alter resistance under load.

The researchers note that unique negative Poisson's ratio behavior in their technology induces inward contraction under compression, concentrating strain in the sensing region and enhancing sensitivity.

Beyond this fundamental mechanism, their auxetic design further strengthens sensor performance in three critical aspects: sensitivity enhancement through localized strain concentration, exceptional performance stability when embedded within confined structures, and crosstalk minimization between adjacent sensing units.

Unlike conventional porous structures, their design minimizes lateral expansion, improving wearability and reducing interference when integrated into devices such as smart insoles or robotic grippers. Furthermore, the use of digital light-processing-based 3D printing enables precise structural programming of sensor performance, allowing for geometry-based customization without changing the base material.

Capacitive Sensing

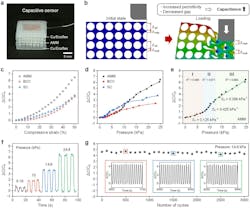

For capacitive sensing, the fabricated capacitive sensor incorporates an AMM core as the sensing layer between two Cu/Ecoflex electrodes (Fig. 2). (Ecoflex is a low viscosity, very soft, strong, and “stretchy" silicone-rubber film.)

In the initial state, the AMM maintains a defined electrode separation with air occupying the voids. Under compression, the electrode gap is reduced and internal air is displaced by the solid elastomeric material, thus increasing the permittivity of the dielectric layer. This dual effect of gap reduction and dielectric densification synergistically contributes to the observed capacitance change, in accordance with the capacitor parallel-plate model.

Resistive Sensing

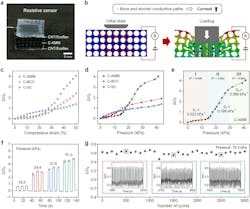

For resistive sensing, they implemented a resistive-type tactile sensor using the same AMM architecture (Fig. 3). To enable piezoresistive sensing, the AMM surface was coated with conductive CNTs, forming a pressure-responsive network. The resulting C-AMM sensor is composed of a CNT-coated AMM core sandwiched between two CNT/Ecoflex composite electrodes, forming a through-thickness conduction pathway.

Upon compression, the AMM exhibits inward contraction due to its negative Poisson ratio, which concentrates deformation toward the structural core and increases the proximity between CNT-coated ligaments. This facilitates the formation of additional micro-contact sites and shortens the inter-electrode distance, collectively enhancing conductivity under load.

For test and evaluation, the team constructed some sensor arrays and other test “objects.” The voluminous details of their project, including concept, analysis, fabrication, and test setups and results can be found in their lengthy and somewhat “intense” paper with informative graphics “Additively Manufactured 3D Auxetic Metamaterials for Structurally Guided Capacitive and Resistive Tactile Sensing” published in Advanced Functional Materials.

The researchers believe that auxetic-structured 3D-printed tactile sensors could be key to next-generation wearable electronics, enabling continuous, high-fidelity monitoring of human movement, posture, and health metrics. Their structural adaptability and material independence could enable creation of custom-fit, application-specific sensors for personalized medicine, advanced prosthetics, and immersive haptic feedback systems. It’s a very extensive and ambitious list!

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.