Elastic-Wave Technology Takes on Touch-Sensing Chores

Check out more TechXchange Talks videos.

What you’ll learn:

- What is elastic-wave touch sensing?

- How does elastic-wave touch sensing compare to capacitive touch sensing?

- How Taifang is using TAIPS on cars.

Capacitive touch sensing is ubiquitous, but it’s only one of many technologies that can be used to determine when someone or something has made contact. Though capacitive touch offers many advantages, it has limitations as well. For example, it’s unable to work in some harsh environments, or the type of touch being detected can be more challenging, such as when a person is wearing a glove.

Some instances of capacitive touch sensing address these challenges. However, alternatives like elastic-wave technology offer many advantages, including the ability to detect the amount of pressure involved in touching a surface.

I talked with Taifang’s Bob Yang about their elastic-wave technology and the Taifang Automobile Intelligent Perception System (TAIPS) (see the video above). Unlike touch sensing for a smartphone screen, TAIPS is designed to address contact with almost any surface on a car.

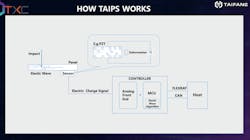

Elastic-wave sensing technology uses a sensor attached to a surface (Fig. 1). This can be used to detect the amount of pressure and the position of the contact. For devices such as touchscreens, it can detect gestures.

The system architecture is similar to a capacitive touch system with a controller that interfaces with the sensors. The main difference is that the elastic-wave technology is passive with the sensor detecting the pressure waves. The controller determines where and how hard the contact is based on the sensor input.

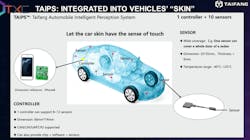

The Taifang Automobile Intelligent Perception System (TAIPS) isn’t set up to detect touch gestures on the surface of a car, but it uses the same elastic-wave sensing technology to determine when something comes in contact with a car, such as a collision (Fig. 2).

Sensors would be placed on surfaces all around the car, from doors to bumpers. The technology can determine the location and pressure involved. One use case would allow a car rental company to determine when damage might have occurred from a major collision to a minor scrape.

Elastic-wave technology works on detecting contact pressure from some object with a surface. This includes any type of object, from a person wearing a wet glove to an exposed finger. The ability to determine where the contact is made enables a system to detect gestures and movement. The accuracy, latency, and pressure sensitivity varies depending on the surface, sensor, and controller.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.