Gas Gauge IC Monitors Lead-Acid Battery State-Of-Health, State-Of-Charge

The bq34z110 gas gauge IC from Texas Instruments provides accurate operating data for lead- acid batteries, a capability not available from other sources. This 14-pin IC (Fig. 1) is the industry’s only scalable gas gauge device that supports multi-cell lead-acid battery packs with battery voltages of 4 V, 12 V, 24 V, 48 V and higher.

Until recently, it has been difficult to accurately measure and report a lead-acid battery’s current capacity. This could frustrate the end user, and require more batteries to ensure an adequate output load. The bq34z110 solves this problem by employing T.I.’s proprietary Impedance Track algorithm that uses voltage, current, temperature measurements, and battery characteristics, to assess battery state-of-charge within 1% error over normal operating conditions.

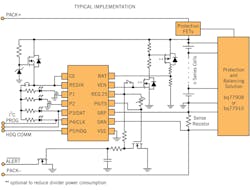

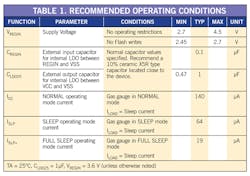

Fig. 2 shows a typical bq34z110 circuit implementation. The bq34z110 gauge continuously informs the user about a lead-acid battery’s state-of-health and state-of-charge and maintains up to a 95-percent accurate capacity measurement for the battery’s entire life. This information prevenqts premature shutdown and increases longevity of the battery and end equipment. An associated host processor can interrogate the gas gauge to obtain cell information, such as remaining capacity, full charge capacity, and average current. Table 1 lists the recommended operating conditions.

Standard Commands in the bq34z110 access battery information, with additional capabilities provided by an Extended Commands set. Both sets of commands are used to read and write information contained within the IC’s control and status registers, as well as its data flash locations. Commands are sent from the host to the fuel gauge IC using HDQ or I2C serial communications engines that can execute during application development, pack manufacture, or end-equipment operation.

The 2-byte Standard Commands consist of two data bytes. Two consecutive HDQ or I2C transmissions must be executed to initiate the command function and to read or write the corresponding two bytes of data. Also, two block commands are available to read the manufacturer name and device chemistry.

Also included in the bq34z110 are 32 bytes of user-programmable, non-volatile data flash memory, accessible via its data flash interface. The data flash memory contains initialization, default, cell status, calibration, configuration, and user information. Cell information is stored in this non-volatile flash memory. Many of these data flash locations are accessible during application development and pack manufacture. They cannot, generally, be accessed directly during end-equipment operation. Access to these locations is achieved by either use of companion evaluation software, through individual commands, or through a sequence of data-flash-access commands.

Most data flash locations, however, can only accessible in UNSEALED mode by use of the evaluation software or by data flash block transfers. These locations should be optimized and/or fixed during the development and manufacture processes. They become part of a Golden Image File and can then be written to multiple battery packs. Once established, the values generally remain unchanged or get updated by the gauge algorithm during end equipment operation.

Two security modes control data flash access permissions:

•Public Access refers to those data flash locations that are accessible to the user.

•Private Access refers to reserved data flash locations used by the bq34z110.

FUEL GAUGING

The bq34z110 measures cell voltage, temperature, and current to determine the battery state of charge (SOC) based on the Impedance Track algorithm. It monitors charge and discharge activity by sensing the voltage across a resistor (5 mΩ to 20 mΩ , typical) between the SRP and SRN pins and in-series with the cell. By integrating charge passing through the battery, the cell’s SOC is adjusted during battery charge or discharge.

When an application’s load is applied, cell impedance is measured by comparing its Open Circuit Voltage (OCV) with its measured voltage under loading conditions. The total battery capacity is found by comparing states of charge before and after applying the load with the amount of charge passed. When an application load is applied, the impedance of the cell is measured by comparing the OCV obtained from a predefined function for present SOC with the measured voltage under load. Measurements of OCV and charge integration determine chemical state of charge and Chemical Capacity (Qmax).

The bq34z110 can use an NTC thermistor (default is Semitec 103AT or Mitsubishi BN35-3H103FB-50) for temperature measurement, or can also be configured to use its internal temperature sensor. It uses temperature to monitor the battery-pack environment, which is used for fuel gauging and cell protection functionality.

To minimize power consumption, the bq34z110 has three power modes: NORMAL, SLEEP, and FULL SLEEP. The bq34z110 passes automatically between these modes, depending upon the occurrence of specific events. Multiple modes are available for configuring from one to 16 LEDs as an indicator of remaining state of charge. More than four LEDs require the use of one or two inexpensive SN74HC164 shift register expanders. A SHA-1 or HMAC-based battery pack authentication feature is also implemented on the bq34z110. When the IC is in UNSEALED mode, authentication keys can be (re)assigned. Alternatively, keys can also be programmed permanently in secure memory. A scratch pad area receives challenge information from a host and also to export SHA-1/HMAC encrypted responses.

The bq34z110 has two flags accessed by the Flags() function that warns when the battery’s SOC has fallen to critical levels. When RemainingCapacity() falls below the first capacity threshold, specified in SOC1 Set Threshold, the [SOC1] (State of Charge Initial) flag is set. The flag is cleared once RemainingCapacity() rises above SOC1 Clear Threshold. All units are in mAh. When RemainingCapacity() falls below the second capacity threshold, SOCF Set Threshold, the [SOCF] (State of Charge Final) flag is set, serving as a final discharge warning. If SOCF Set Threshold = –1, the flag is inoperative during discharge. Similarly, when RemainingCapacity() rises above SOCF Clear Threshold and the [SOCF] flag has already been set, the [SOCF] flag is cleared. All units are in mAh.

The bq34z110 has two additional flags accessed by the Flags() function that warn of internal battery conditions. The fuel gauge monitors the cell voltage during relaxed conditions to determine if an internal short has been detected. When this condition occurs, [ISD] will be set. The bq34z110 also has the capability of detecting when a tab has been disconnected in a 2-cell parallel system by actively monitoring the state of health. When this condition occurs, [TDD] is set. Lead-Acid gauging in the charge direction makes use of four Charge Efficiency factors to correct for energy lost due to heat. Lead-Acid charge efficiency is not linear throughout the charging process, as it drops with increasing state of charge.

X10 MODE

The bq34z110 supports high current and high capacity batteries above 32.76 Amperes and 32.76 Ampere-Hours by switching to a times-ten mode where currents and capacities are internally handled correctly, but various reported units and configuration quantities are rescaled to tens of milliamps and tens of milliamp-hours. The need for this is due to the standardization of a two byte data command having a maximum representation of ±32767.

When the X10 bit (Bit 7) is set in the Pack Configuration register, all of the mAh, cWh, and mWh settings will take n a value of ten times normal. When this bit is set, the actual units for all capacity and energy parameters will be 10 mAh or Wh. This includes reporting of Remaining Capacity. This bit will also be used to rescale the current reporting to 10 times normal, up to ±327 A. The actual resolution then becomes 10 mA.

It is important to know that setting the X10 flag does not actually change anything in the operation of the gauge. It serves as a notice to the host that the various reported values should be reinterpreted ten times higher. X10 Current measurement is achieved by calibrating the current gain to a value X10 lower than actually applied. Because the flag has no actual effect, it can be used to represent other scaling values.

VOLTAGE DIVISION AND CALIBRATION

The bq34z110 is shipped with factory configuration for the default case of 2-series lead-acid cell. This can be changed by setting the number of series cells in the data flash configuration section.

Multi-cell applications, with voltages up to 65535 mV may be gauged by using the appropriate input scaling resistors such that the maximum battery voltage, under all conditions, appears at the BAT input as approximately 900 mV. The actual gain function is determined by a calibration process and the resulting voltage calibration factor is stored in the data flash location Voltage Divider.

For two-cell applications, an external divider network is not required. Inside the IC, behind the BAT pin is a nominal 5:1 voltage divider with 88 KΩ in the top leg and 22 KΩ in the bottom leg. This internal divider network is enabled by clearing the VOLTSEL bit in the Pack Configuration register. This ratio is optimum for directly measuring a dual cell lead-acid cell where charge voltage is limited to 5 V max.

For higher voltage applications, an external resistor divider network should be implemented as per the reference designs in this document. The quality of the divider resistors is very important to avoid gauging errors over time and temperature. It is recommended to use 0.1% resistors with 25 ppm temperature coefficient. Alternately, a matched network could be used that tracks its dividing ratio with temperature and age due to the similar geometry of each element.

AUTO CALIBRATION

The bq34z110 provides an auto calibration feature that will measure the voltage offset error across SRP and SRN from time-to-time as operating conditions change. It subtracts the resulting offset error from normal sense resistor voltage, VSR, for maximum measurement accuracy.

The gas gauge performs a single offset calibration when (1) the interface lines stay low for a short time. The bq34z110 can act as a SHA-1 and HMAC authentication slave by using its internal engine. Sending a 160-bit SHA-1 challenge message to the bq34z110 causes the IC to return a 160-bit digest, based upon the challenge message and hidden plain-text authentication keys. When this digest matches an identical one, generated by a host or dedicated authentication master (operating on the same challenge message and using the same plain text keys), the authentication process is successful.

EVALUATION MODULE

The bq34z110EVM evaluation module (Fig. 3) is a complete evaluation system for the bq34z110 wide-range fuel gauge for lead-acid chemistries when combined with an EV2300 USB adapter and Windows®-based PC software, downloadable from the TI.com website.

The circuit module includes one bq34z110 integrated circuit (IC) and all other components necessary to monitor and predict capacity in 2 or more series cell Lead Acid battery packs. The circuit module connects directly across the battery.

With the EV2300 interface adapter and software, it is possible to read the bq34z110 data registers, program the chip for different pack configurations, log cycling data for further evaluation, and evaluate the overall functionality of the bq34z110 solution under different charge and discharge conditions.