How to make bus A/C more efficient: Add a CVT

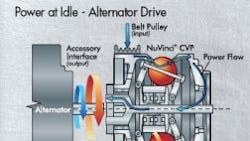

Fallbrook Technologies Inc. says it was able to replace a 330 cc AC compressor with a smaller 210 cc unit by coupling the compressor to its NuVinci Delta Series continuously variable planetary (CVP) transmission. The unit sat inside a bus made by Chengdu, Ltd.in China.

The company says the main benefit of adding its CVP tranmission is that the compressor need no longer be sized to handle worst-case conditions at low engine speed.

Fallbrook says transit buses, government trucks and commercial vehicles share a common air conditioning problem – namely that a belt-driven AC compressor is undersized for the refrigerating capacity desired because available space in the engine compartment limits compressor size. The NuVinci compressor drive is designed to deliver the right compressor speed all the time – optimizing AC operation and performance and thus increasing system efficiency.

Unlike conventional gear and clutch transmissions, the NuVinci CVP uses a set of rotating and tilting balls positioned between the input and output components of the transmission that tilt to vary the speed of the transmission. Tilting the balls changes their contact diameters and varies the speed ratio. As a result, the NuVinci CVP offers a seamless and continuous transition to any ratio within its range.

The company presented its simulated drive test findings as well as the technical specifications for its AC and alternator accessory drive products at the Society for Automotive Engineers' Commercial Vehicle Engineering Congress in Rosemont, Ill.

More information is available at http://www.fallbrooktech.com/03_CVAD.asp.

http://machinedesign.com/article/a-cvt-in-a-compact-efficient-package-0616