Programmable Linear Hall Sensor Exhibits High Stability

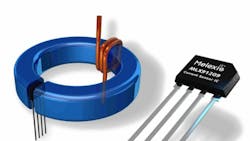

Melexis has introduced a linear Hall sensor for use as a current sensor. With its fast response time and improved stability over operating temperature and over lifetime, the MLX91209CA is optimized for demanding current sensing applications.

Measuring electrical current in a conductor is critical to many systems. Classic measurement techniques use shunt resistors, current transformers or magnetic field sensors. Hall Effect sensors are frequently the choice when measuring DC currents. However the new, improved MLX91209CA can be applied in all current sensing situations. This versatile, high speed Linear Hall IC, which features a programmable sensitivity range from 5 to 150 mV/mT, is suitable for measuring DC and AC currents up to 200 kHz.

The MLX91209CA's strong thermal and lifetime stability provides design engineers with fully programmable critical characteristics - allowing one single part to meet a wide variety of current sensing applications. Parameters such as sensitivity and offset are stored in an internal EEPROM memory. Calibration is done using Melexis' well-established, proprietary PTC (Programming Through Connector) protocol. This modulates the supply voltage and does not require any additional pin for programming, enabling the most efficient production flows. A linear analog output permits use of the sensor in applications where a very fast response of 3 µs is required.

Custom calibration is best performed in-situ after the sensor is fixed with respect to the current conductor and ferromagnetic core so that a calibrated current sensitivity is achieved. Typical accuracy of a current sensing system based on the MLX91209 is better than ±0.5% at room temperature or ±2% over the full temperature range (from -40 °C to 125 °C) when applying in-circuit end of line calibration. The device is supplied in a 4-pin SIP, RoHS compliant lead-free package.

Demand for current sensing solutions is growing rapidly with the increased proliferation of alternative vehicles, like Hybrid Electric, Electric and Start/Stop equipped 'Mild Hybrids'. Battery management systems rely on accurate and stable current sensing to control the charge/discharge cycles. Proper management of the current in and out of modern batteries is essential for safety, battery service life and, in full electric vehicles, predictable range calculation.

Continued investment in Solar Power generation and other grid connected energy sources demand accurate and stable monitoring to safely operate on the rapidly expanding 'Smart Grid'. Here, once again, current sensing is key to the control systems, for the effective integration of small to medium scale power generation systems.

In addition, current sensing is instrumental in the management of power in more traditional electronic systems. Power distribution systems in large scale server installations rely on current sensing to deliver high levels of up-time and predictive maintenance.